Impact Factor : 0.548

- NLM ID: 101723284

- OCoLC: 999826537

- LCCN: 2017202541

Emin Taner Elmas*

Received: July 26, 2024; Published: August 05, 2024

*Corresponding author: Emin Taner Elmas, Assistant Professor Dr., Vocational School of Higher Education for Technical Sciences, Division of Motor Vehicles and Transportation Technologies, Department of Automotive Technology, Iğdır University, Turkey & Graduate School of Natural and Applied Sciences - Major Science Department of Bioengineering and Bio-Sciences, Iğdır University, Turkey

DOI: 10.26717/BJSTR.2024.58.009087

This article gives a general information about the Combined Cycle Power Plants which is an energy production

system allowing to produce Steam, Heat and Electricity together in an energy efficient way. Combined cycle

is the alternative power generating system which provides maximum efficiency and minimum impact on the

environment. Off all processes available today for power generating in industry and utilities, there is no doubt

that the combined cycle system offers the best prospects for the future. [1-27]

Combined cycle system has great development potential in the fields of technology and application and features

above all; environmental compatibility, greater fuel efficiency, lower investment costs with a faster rate of

amortisation. The present state of gas turbine technology featuring a wide range of outputs allows for a great

variety of applications in many different fields. These include; smaller in-plant power supply units for factories

needing process heat for production, industrial power plants, utilities for district heating. Here, of course we

are referring not only to building new power or heat facilities but also to upgrading or retrofitting existing ones.

[1-27]

Keywords: Combined Cycle Power Plant, Waste Heat Recovery Boiler, WHRB, Heat Recovery Steam Generator, HRSG, Co-generation, Electricity, Three-Pass Fire Tube Boiler, Steam Generator, Steam, Hot Water, Superheated Water, Energy, Energy Efficiency, Energy Transfer, Heat Energy, Thermodynamics, Fluid Mechanics, Heat Transfer, Mathematics, Energy Production Systems., Gas Turbine, Gas Motor, Motor, Thermal Energy, Energy Economy

The most important reason for the extension works on a power station is the need to reduce emissions to meet statutory requirements. A combined cycle unit is installed which not only to accomplish this but also to improve efficiency. As an example, the 25 MW gas turbine supplies exhaust gas heat to a water tube heat recovery boiler with refinery gas supplementary firing to generate 120 t/h superheated steam at 135 bar and 535°C. The unfired steam production is approx. 40% of the nominal output. The superheated steam thus generated drives the steam turbine [1-27]. For combined cycle projects, designing and installation of the main components, such as the steam and heat generators is the most important stage. In each case, the boiler is “tailor-made” to match the given process and plant conditions in every aspect. Designing and installation of combined cycle units for new plants where overall efficiency of the in-plant energy supply and emission control are top priorities, as well as upgrading industrial power plants using the existing boilers or turbines. The combined cycle is the name given to a power generating block consisting of a gas turbine, a boiler and a steam turbine. The boiler provides the link between the two turbines. The gas turbine combined cycle consists of a gas turbine linked up to a steam or hot water generator which, in most cases, is also fitted with supplementary firing [1-27].

A general overview of rated outputs as; gas turbine output – steam / heat generation is stated at Table 1 as below. Turbines linked up to the power boiler steam and hot water generators are suitable for most of existing thermal power plants. Gas turbines are so highly developed nowadays that they can operate cost effectively whilst keeping emissions down to a minimum. The main fuel used to drive the combustion engine (gas turbine) is natural gas. Diesel or naphtha is also possible. Gas turbines today, depending on model and size, reach efficiency levels of about 30%. NOx levels are below the statutory requirements. Further reductions are partly possible by modifying the combustion chamber or by steam or water injection. The turbine exhaust with temperatures ranging from 460 – 560°C and an oxygen content of approx. 15%, provides a valuable source of energy. This is the basic principle of the gas turbine function in combined cycles for generating the electricity supply and processing heat required in an industrial plant. Figure 1 shows the various arrangements for combined cycles [1-27].

The following alternatives can be realized for utilizing the exhaust

gases.

1. Using only the tangible heat of the exhaust until it is reduced

to the outlet temperature. This depends on the medium

(pressure and temperature) used in the secondary process.

2. Using the tangible heat and the oxygen content of the exhaust

to provide the oxygen supply necessary for the supplementary

firing unit.

As a general description, “Combined Cycles” mean the electricity

generation with gas turbine steam or hot water production with a

Waste Heat Recovery Boiler / Heat Recovery Steam Generator (WHRB

– HRSG).

The general arrangements may be summarized as follows:

1. Gas turbine – heat recovery boiler

2. Gas turbine – heat recovery boiler with supplementary firing

3. Gas turbine - heat recovery boiler with supplementary firing

and FD fan

4. Electricity generation with both a gas and a steam turbine /

process steam from steam turbine

5. Gas turbine – heat recovery boiler with / without supplementary

firing – steam turbine

6. Gas turbine – heat recovery boiler with / without supplementary

firing – steam turbine providing process heat

7. Gas turbine – heat recovery boiler with supplementary firing

and FD fan – steam turbine with or without process heat [3].

Boilers with natural circulation, forced circulation or with multiple-

pressure configurations are used. Water-tube boilers, fire-tube

boilers or boilers with a combination of both systems to suit requirements

such as output, pressure, the medium used and site conditions,

can be supplied. For simple combined cycles, each heat recovery

boiler is tailored to accommodate the gas turbine. The boilers are

supplied in shop assembled modules with a fixed range of boiler capacities.

For complex combined cycles the boiler is designed specifically

to accommodate both the gas and the steam turbine. In general,

maximum shop assembled boilers of 100 t/h steam output in one

unit or in appropriately large sections can be obtained. This allows

shop assembly under continuous quality control instead of costly,

time-consuming field assembly. Combined cycles do not rely on any

special make of turbine. All internationally proven turbine models are

used [1-27]. Hardly any other energy conversion process apart from

pure heat generation, achieves fuel combustion efficiency levels of

90°C comparable with combined cycles generating process heat. Less

fuel means lower operating costs and lower emissions. A comparison

clearly shows the high efficiency levels which typify combined cycle

processes, as below.

1. Gas turbine operation solely for generating electricity = approx.

30%

2. Conventional power station with condensation steam turbine

= approx. 40%

3. Combined cycle with gas turbine and condensation steam

turbine = approx.52%

In the last case, the “tailor-made” boiler is a highly important factor

and is decisive for the efficiency of the entire plant. Figure 2 shows

the heat power flow for combined cycle [1-27]. As an example of retrofit

work of a conventional industrial power plant in the chemical industry

and install a combined cycle unit to increase efficiency, reduce

emissions and meet the higher demand for process heat. The 1.3 MW

gas turbine with a directly fired water tube heat recovery boiler (with

dual drum design) is installed. The boiler is designed to raise 27 t/h

superheated steam at 32 bar and 325°C. This can be increased to 40

t/h by switching on the forced air fan in conjunction with supplementary

firing by natural gas. Unfired boiler operation (approx. 25% of

boiler output) is possible. Higher efficiency means faster amortisation.

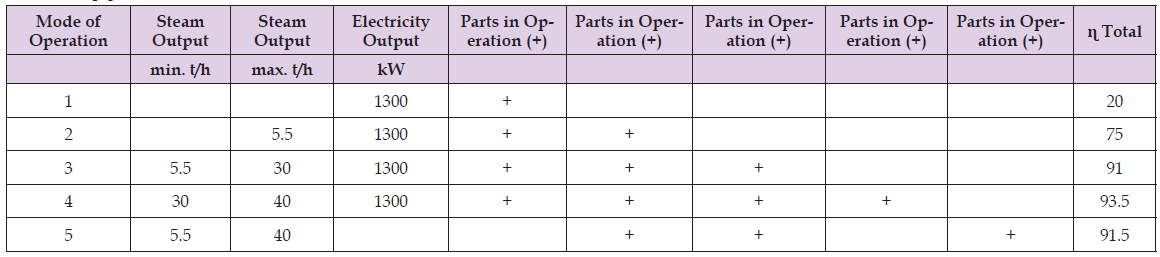

Table 2 shows the fuel combustion efficiency during different

modes of operation of the combined cycle block. The combined cycle,

consisting of gas turbine and directly fired steam boiler with its own

forced air fan and steam turbine, assures optimum performance for

power generation in any industrial plant. The flexibility of this process

allows the following variations [3].

Table 2: The fuel combustion efficiency during different modes of operation of the combined cycle block. Higher efficiency means faster amortisation [3].

1. Gas turbine generating electricity ………emergency stack

2. Electricity and approx. 25% steam generation with turbine

exhaust heat, boiler unfired.

3. Electricity and 100% steam generation, boiler with supplementary

firing. Process heat supply by using a back pressure

turbine.

4. Electricity and 100% steam generation by independent boiler

operation with forced air fan. Process heat supply by using

a back pressure boiler.

5. Switch-over from one system to the other is automatic and

without interruption of the electricity and steam supply [3].

In planning the design of a combined cycle unit with supplementary

firing, provision is normally made for burner forced air supply.

The following equipment are necessary; flow burner with ducts for

turbine exhaust and forced air, natural gas supplementary firing

(burners) for a combined cycle boiler of a determined capacity, ventilator

complex for automatic switch over to forced air and vice versa

[3]. As an example of upgrading and reducing emissions in an industrial

power plant by installing a combined cycle block is explained as

follows; this consists of a 9 MW gas turbine and a water tube boiler

with a superheated steam output of 110 t/h, 75 bar, 510°C. The following

modes of operation for steam generation are possible.

1. Unfired heat recovery operation……12 t/h

2. Combined operation of gas turbine and boiler with supplementary

firing……110 t/h

3. Boiler operation with forced air only…….110 t/h

The superheated steam thus generated supplies the steam turbine

block. Emissions are stated as follows.

1. NOx – boiler operating at full capacity…….160 mg/m3

2. CO – boiler operating at full capacity……...100 mg/mg/m3

Boiler efficiency when combined cycle is in operation with gas turbine at full capacity will be 93% [3]. Combined cycle for energy supply in industrial plants may have the following basic block: gas turbine – superheated steam generator – steam turbine – process heat. Another example is related with the primary materials industry for a power installation to supply 180 t/h process heat while at the same time generating 32 MW of electricity. As the main priorities are higher efficiency, flexibility and low emissions, it is decided to integrate a combined cycle block into the existing power generating plant. The exhaust gas flow from the new 15 MW gas turbine to the heat recovery water tube boiler generates 140 t/h superheated steam at 98 bar and 525°C. This output is achieved using a combination of turbine exhaust heat and natural gas firing, installed as duct burners in the boiler. Fresh air firing can achieve the same output without turbine exhaust gases. Pure heat recovery operation can yield 25% of this output. To reach the required steam output of 180 t/h, a second superheated steam boiler is integrated into the turbine exhaust gas flow. Conditions on site required the application of special flow technology to guarantee the necessary operational flexibility of the plant [1-27]. Combined cycles for public utilities are used for electricity and heat generation. Another example is about a peak-load gas turbine power plant and the mentioned plant is built to supply a city with electricity. Two hot water heat recovery boilers with thermal output of 9.3 MW at 20 bars are operated on the exhaust gas flow from two 5 MW gas turbines.

The heat generated is fed into the district heating network. This combined cycle block operates in accordance with German TRD 604 without continuous supervision. The combined cycle process used for district heating supply has an efficiency level of over 90%, depending on the turbine output. For large cities, this means a considerable reduction in emissions. The medium is mostly hot water which is distributed according to the supply system [1-27]. A combined cycle block is integrated into an existing district heating plant with a total output of 50 MW. The gas turbine covers all in-plant energy requirements feeding surplus electricity into the grid. The heat recovery boiler linked to the gas turbine is a modified three-pass fire tube boiler which operates as follows; an output of 10 t/h of saturated steam at 17 bar is raised by turbine exhaust gases in the first boiler pass which has the largest heating surface. On leaving this pass, part of the cooled down gas is diverted to the burners which are located directly beside the fire tube. Supplementary firing can increase output to 18.7 t/h. This part of the exhaust gas is further cooled down in the third boiler pass. The different exhaust flow sections come together in the economiser. The final temperature reading of the exhaust gas is 130°C. Here, the combined cycle includes boiler, turbine, steam circuits with heating surfaces and forms a combined cycle block. Combined cycle featuring 0.8 MW gas turbine with a heat recovery steam output of 2.6 t/h at 13 bar and combined cycle featuring 0.6 MW gas turbine with a heat recovery steam output of 2.2. t/h at 10 bars are also possible configurations [1-27].

Combined cycles (gas turbine – unfired heat recovery boiler) are used, for example, in the field of process heat generating and for heating purposes, provided electricity consumption is as continuous as possible and heat requirements are constant. As another example, a textile plant requiring higher efficiency and lower emission levels in its power generation unit installed a combined cycle block. The block consists of 2 gas turbines with an electricity output of 1.1 MW each. Two heat recovery boilers operating on turbine exhaust quantities of 7.4 kg/s each, generate a total of 6.9 t/h saturated steam at 25 bars. This steam flow, passing through reduction stations, supplies the various processes with differing steam pressures (25, 10 and 3.5 bar). The boilers installed are designed as condenser – economiser – finned tube systems with attached steam drums. The technical specifications of another combined cycle block are as follows; the combined cycle block with dual 1 MW gas turbines and a boiler system producing 29 t/h at 10 bars of steam [1-27]. Combined cycles used in generating electricity for factory requirements are also economic and environmentally compatible for medium sized industrial plants [1-27]. Fire tube boilers are particularly suitable for heat recovery when smaller gas turbines are used. Modified fire tube boilers or heating surfaces are normally installed when supplementary firing is to be used. The boilers operate on a natural circulation basis. The boiler can be also equipped with a by-pass depending on plant requirements.

This enables the gas turbine to remain in operation when heat requirements decrease. It can also remain in operation when disruptions occur in the heat application areas. Economisers and service water heat exchangers usually prove effective in improving the temperature reduction of the flue gas. Fuel-steam output relationship of the combined cycle with fire tube boiler is given by diagrams. As an example, a combined cycle block with a medium range output is installed in a milk processing plant. This is necessary because of changes in the production process which involved increased electricity requirements and because of stricter legislation on emission control and above all the need for a more economic power supply. The boiler system utilizing the exhaust from 1.1 MW turbine and with supplementary firing generates 28 t/h superheated steam at 28 bar and 250°C. This is chanelled trough the existing main steam piping to the steam turbine and used as process steam for production. The boiler can be operated on a heat recovery basis (approx. 25% of the nominal output) or with fresh air firing without turbine exhaust. Combined cycle block is tailored to fit into the existing boiler house, superheated steam generator (heat recovery boiler), supplementary firing with fresh air, exhaust gas ducts are the main parts of the block diagram [1-27]. There are several erection variations which are open air site erection, installation in buildings or integration into existing power complexes. Local site conditions not only determine the type of boiler to be used but also the mode of erection, as for example mentioned below.

1. Heat recovery boilers and directly fired boilers in vertical position

to fit into tight spaces.

2. Horizontally installed modular designed boilers are also

available as package boilers for open air sitting.

3. Installation of boiler in a purpose-built or existing boiler

house.

An example is a boiler house with two superheated steam generators in a combined cycle block producing 72 t/h of steam each at 52 bar and 500°C. Another heat recovery boiler system linked to a 25 MW gas turbine with natural gas supplementary firing and fresh air fans for 100% boiler output. Steam output 88 t/h, 34 bar, 410°C. The following modes of operation are possible.

1. Combined cycle with turbine exhaust used as combustion air.

2. Boiler operation with fresh air firing and without gas turbine.

3. Automatic switchover from one mode to the other.

The walls of the combustion chamber at the boiler inlet consist of welded flue gastight tube walls to maintain an even temperature profile at the inlet and on the heating surfaces. Regulation of the superheated steam temperature is affected by means of a spray attemperator. A bypass is installed on the flue gas side for start-up and switch-over to the various process operations [3]. Heat recovery boilers are mostly modular designed. The modular design system maximises the degree of shop assembly and can also be applied to large boilers. It can be used for virtually all combined cycle blocks generating saturated and superheated steam; generation at multiple-pressure levels is also possible. Advantageous manufacturing facilities and convenient transport conditions made complete shop assembly feasible. This left only joint assembly of pipes and electrical installations to be done on site. That virtually means shop assembled delivery without any complicated assembly or installation on site. As an example, the boiler having a heat recovery system with supplementary firing which is in the connecting duct between gas turbine and boiler. Boiler output: 130 t/h, 18 bar, 340°C. Another example is a combined cycle in a refinery. The natural circulation heat recovery boiler system is linked to a 36 MW gas turbine. The supplementary firing is designed for natural and refinery gas. Boiler and connecting pipes have interior insulation. The boiler is completely drainable. Boiler data: 170 t/h, 42 bar, 400°C. The steam generated flows onto the steam turbine or is used to drive the compressors or applied as process heat [1-27].

The combined cycle block gives also an opportunity to provide a flexible power plant operation.

The concept for supplying a chip board factory with electricity is as follows.

1. Electricity generation with a sander-dust fired superheated

steam boiler linked to a steam turbine.

2. Electricity generation with gas turbine linked to a hot water

generator.

The combination of both processes guarantees a safe, inexpensive and environmentally compatible supply of production heat which include hot water generation – utilization of flue gas heat from the sander- dust combination for drying purposes – utilization of exhaust heat to pre-heat feed water – utilization of turbine waste steam to heat other media. Data is as follows; gas turbine 5 MW, steam turbine 2.6 MW, hot water output 14.5 MW, superheated steam output 32 t/h. Boiler house of the combined industrial power block, combined hot water boiler for turbine exhaust with supplementary firing are the parts given on the power block diagram. A similar example of power utility includes a combined cycle block having the data of total electricity output 23.5 MW and boiler output 31.5 t/h, 28 bar, 140°C [1-27].

Figures 3 & 4 show the “combined cycle for energy supply in industrial plants; gas turbine – superheated steam generator – steam turbine – process heat [3]. Figures 5 & 6 show the combined cycle for public utilities; electricity and heat generation [3]. Figures 7 & 8 indicate that combined cycles used in generating electricity for factory requirements are also economic and environmentally compatible for medium sized industrial plants [3]. Figure 9 shows a Heat Recovery Stream Generator (HRSG) / Waste Heat Recovery Boiler (WHRB). Figure 10 shows an example of combined cycle block diagram [3]. This article gives general information about the Combined Cycle Power Plants which is an energy production system allowing to produce Steam, Heat and Electricity together in an energy efficient way. All the data, figures and tables given by this study, show sample values, illustrations and notation [1-27].