Impact Factor : 0.548

- NLM ID: 101723284

- OCoLC: 999826537

- LCCN: 2017202541

Seongwoo Woo* and Song-Jung Kim

Received: May 21, 2024; Published: June 03, 2024

*Corresponding author: Seongwoo Woo, Myungsung Medical College, Ethiopia

DOI: 10.26717/BJSTR.2024.56.008913

To upraise the fatigue lifetime of mechanical product randomely shaked during transportation, parametric Accelerated Life Testing (ALT) is offered as structured way, which is produced in sample size and life–stress model. These organized steps let designer to detect the design frailty which has a noteworthy effect in product reliability. In the long run, company can bring to cease recalls from the marketplace. For a manifestation, elevating the lifetime of system worked by machinery in transportation was inspected [1].

Keywords: Parametric ALT; Product Functioned by Machine; Transportation; Fatigue; Design Frailty

The system functioned by machinery brings (produced) power to maintain an organized effect that entails movement & forces and gets mechanical advantages by precisely realizing undisclosed mechanisms. By conducting the vapor compression cycle, a domestic refrigerator lets cooled air from evaporator to refrigerator and freezer division. In the meantime, foods in refrigerator and freezer department may be held recently. Refrigerator is arranged of compressor, condenser, capillary, and evaporator [2]. It might be designed to correctly function over the conditions truly deployed by the consumer. If there are design frailty, product may not instantly function in its assumed lifetime (Figure 1). As finding design frailty by reliability testing and modifying it, an engineer can optimally function it [1]. This organized procedure detains:

(1) ALT scheme,

(2) Load scrutiny,

(3) ALTs with modifications, and

(4) The consideration to discern whether product gets to the

designed BX life. For a case investigation, the mechanical product

during transportation will be inspected.

We adopted a cross-sectional study design to determine healthcare workers’ knowledge, attitudes, and practices (KAP) during the COVID-19 pandemic. The study was conducted via a self-administered questionnaire to 373 healthcare workers in five selected healthcare facilities in the Ashanti region sampled through the multistage random technique. There is no standardised and validated device for assessing KAPs on COVID-19. The questionnaire was constructed from two questionnaires that were previously used to determine healthcare workers’ KAP towards COVID-19. Sections of the instruments of Limbu et al. and Kamali et al. were used [6,7].

Knowledge and attitude were assessed using a five-point Likert scale, and scoring was conducted by assigning numbers 1-5 to the scale: strongly agree - 5; agree - 4; neutral - 3; disagree – 2; strongly disagree -1. The more frequent answers of 4 and 5 revealed adequate knowledge and a positive attitude, whereas limited knowledge and negative attitude were indicated by more frequent scores of 3 and below. The scoring of the practices of the healthcare workers towards COVID-19 prevention was conducted by assigning 0 to an incorrect answer and 1 to a correct answer. The practice questions were 17 with three options (Yes, NO, and lack of facility/inadequate equipment). The total score was calculated and divided by the number of questions and later multiplied by 100 to obtain the cumulative percentage. The respondents who scored 80%-100% on the knowledge, attitude, and practice questions were considered to have very good knowledge, excellent attitude, and practices 60%-79% had good knowledge, attitude, and practices, and a score less than 60% was considered limited knowledge, poor attitude, and poor practices. The questionnaire comprised 60 items, of which almost all were close-ended questions.

1. Part 1: Comprises the demographic information and source

of information on COVID-19.

2. Part 2: Focused on questions about the respondents’ knowledge

of COVID-19,

3. Part 3: Included questions on the respondents’ attitude towards

COVID-19,

4. Part 4: The respondents answered questions about

COVID-19 prevention.

Parametric ALT in System Functioned by Machinery

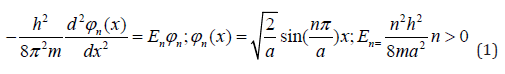

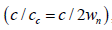

Finding in the Schrodinger’s mathematical problem can be discovered:

Linear transport shall be indicated:

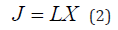

For an incident, solid-state diffusion, J, shall be condensed

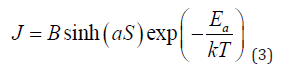

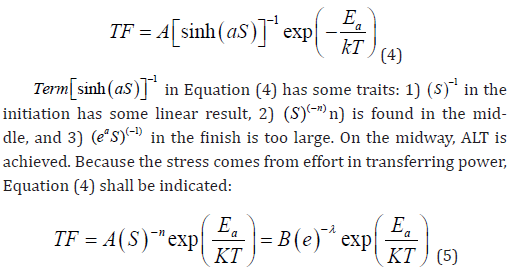

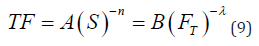

When Equation (3) takes the reverse, the life-stress (LS) model can be elucidated:

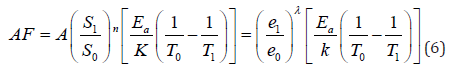

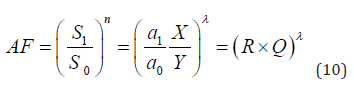

To find the acceleration factor (AF), announced by the relation between the elevated-level stress and common stress, AF may be expressed as:

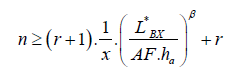

To reach the allocated time for designed lifetime - B1 life of ten years, sample size united by Equation (6) can be indicated as [2]:

Case Examination: Refurbishing the Fatigue Lifetime of a Household Product Subjected to Random Shakes in Transported by Railroad

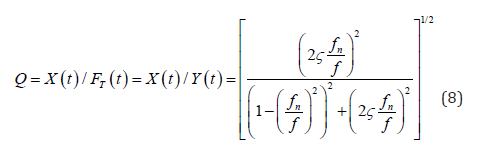

Refrigerators were conveyed from the LA situated in the western coast of the U.S. to consumers who lived in the US, the part of the country near the Atlantic Ocean. This trip for an entire travel period – seven days – was 7,200 km. As uttered by market data, after products subjected to random vibrations on rail transit way were transported, refrigerators did not work because the mount rubbers & soldering in compressor were fatigued and the connecting tubes were broken, going along with engineers to request for taking the place of it. Namely, in the US, the interval when earliest failure occurred for two days was approximately 2,500 km during rail transportation. In Chicago, 27% of the carried refrigerators was failed. As the products transported the 7,200-km distance from the western coast of the U.S. to Boston, 67% of the refrigerators was failed. It was evident that the unsuccessful refrigerator had design frailties. To rightly work the product within its assumed lifetime during transportation, as recognizing them by parametric ALT, the company had to alter them (Figure 2). Because of the basis load, Y, force transmissibility, Q, may be defined:

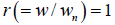

where X is the unchanging solution on the mechanical system, FT

is the applied force, Y is the extent of foundation excitations, r is the

frequency ratio  is the damping proportion

is the damping proportion

K is the spring constant.

K is the spring constant.

As the stress during transit originates from the transported vibration loads, FT, which can be expressed as the power spectral density (PSD) of acceleration on the regulated frequency band, Equation (5) can be defined:

So, discovered on Equation (6), AF may be indicated:

where a1 is the elevated PSD on the assigned frequency band, a0

is the common PSD on the assigned frequency band, R, is amplitude

proportion of gravitational acceleration. As inspecting the computed

vibration, the natural frequencies for horizontal and vertical vibration

were 5 Hz and 9 Hz. The damping proportion was anticipated

to be ς = 0.1 with a settling period of 2 sec and approximately 5.3

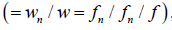

overshoot. The frequency ratio at the natural frequency ωn also was

anticipated to be r  .

.

To attain the AF of random shakes found from the field, elevated PSD to the product were applied to the shaking table for each orientation (Figure 3). From Equation (8), the force transmissibility, Q, had the magnitude of approximately 5.3. Due to acceleration of 1 Grms, the AF was 4.0, roughly calculated to that of worst-case of 0.25 Grms. Employing a cumulative damage constant, λ , of 2.0, the entire AF from Equation (10) was set to be 450.0. As the calculated shape parameter on Weibull plot was 6.41 and the life aim – B1 life for the whole travel distance had, for three samples, the test time attained from Equation (7) was approximated to have 40 min. Namely, if the refrigerator was failed less than once in assigned period – 40 min., product was suitable for the whole travel distance of 7,200 km to live the product fatigued because of random vibration.

Results and Conclusions

In the 1st ALT, the unsuccessfulness for the stress — 1.00 Grms at the natural frequency (r = 1.0,ς ≈ 0.1) were found. Namely, for these circumstances, at 20 min, mount rubber & soldering were fatigued and tubes on the samples were broken. It happened because of no pillar in the area of stress raiser for the mount rubber to endure the random loads because of parallel vibrations. As action plans, the product was redesigned as the altered rubber mount in compressor, C1 (Figures 4 & 5). In 2nd ALT, the product is successful till 60 min. When product reached at an acceleration of 1.00 Grms in the shake table, the natural frequency on the parallel direction was altered from 5Hz to 8 Hz by the enlarged damping (Figure 6). To enlarge the fatigue lifetime of refrigerator during transit, ALT was developed. The quantum- conveyed life-stress model and sample size were suggested. As an occasion inpsection, enhancing the lifetime of a product fatigued by random vibrations in rail transportation was investigated. As the mount rubbers in compressor was redevised, there were no issues for assigned time – 40 min. So, the product was assured to endure the fatigue produced and fulfil the refrigerator lifetime – B1 life for the whole travel distance.