Impact Factor : 0.548

- NLM ID: 101723284

- OCoLC: 999826537

- LCCN: 2017202541

Seongwoo Woo1*, Dennis L O’ Neal2, Yimer Mohammed Hassen1, Gezae Mebrahtu1 and Hadush Tedros Alem1

Received: April 08, 2024; Published: April 18, 2024

*Corresponding author: Seongwoo Woo, Manufacturing Technology, Mechanical Technology, Ethiopian Technical University, Addis Ababa, Ethiopia

DOI: 10.26717/BJSTR.2024.56.008820

To raise the design life of mechanical product such as enclosure system in the refrigerator, parametric Accelerated Life Testing (ALT) as methodical plan is proposed, brought by life–stress model and sample size. These systematic strategies allow engineer to disclose the design defects which have a noticeable consequence on product reliability. Ultimately, company will come to a recall stop from the field. As a test instance, upraising the life of system functioned by machine such as enclosure product in the refrigerator was carefully scrutinized.

Keywords: Mechanical System; Parametric Alt; Enclosure; Pitting Corrosion; Design Defects

The system performed by machine conveys (built) power to hold a planned effect which demands forces & motion, acquiring mechanical advantages through fairly completing some mechanisms. For instance, by accomplishing the vapor-compression refrigerating cycle, refrigerator lets cooled air from heat exchanger to freezer & refrigerator section. So, reserved foods in the refrigerator can be kept for some perioded time under the happenings really deployed by the end-user. That is, if there are constructional defects on the structure, it will not quickly function within its presumed lifetime (Figure 1). As unexpectedly observing it by some tests in the laboratory, an engineer shall conceive it by the most satisfactory method [1]. It keeps:

1) ALT program,

2) Load inquiry,

3) ALTs with diverse improvements, and

4) Judgment if system achieves the objective BX life. For a demonstration

inquiry, the mechanical product such as enclosure system

in the refrigerator will be studied.

Parametric ALT in Product Performed by Machine

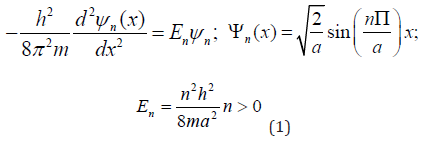

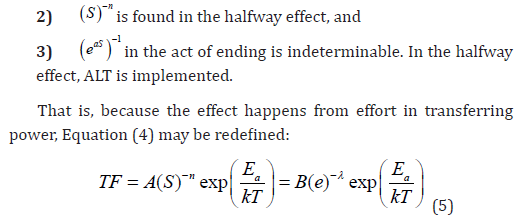

Replying on the time independent Schrodinger’s equation shall be stated:

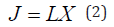

Linear transport can be stated:

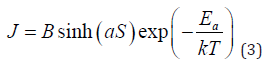

For a certain happening in the semi-conduct, solid-state diffusion may be abbreviated

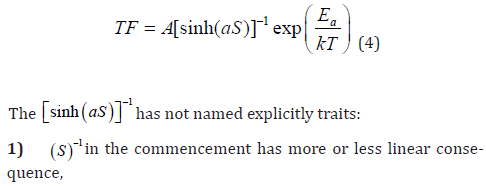

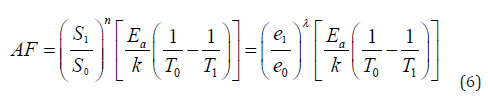

As junction function in Equation (3) sets the reverse, the lifestress (LS) protype can be expressed:

To stretch out the acceleration factor, signified by the association between the upraised stress and routine stress, AF can be expressed:

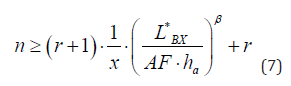

To secure the allotted time for objective lifetime – B1 lifetime of ten years, sample size coalesced with Equation (6) shall be expressed [2]:

Enhancing the design life of cooling enclosure in the household refrigerator pitted in the market. As the maximum amount contained in the refrigerator, end-user wants to utilize the refrigerator to keep the reserved food fresh. To satisfy these suppositions, the enclosure system in a household refrigerator is invented to clasp the absolutely necessary food over forecasted customer circumstances in its system life. The main components in the cooling enclosure comprises of the following:

• Inner Case,

• Evaporator Tube,

• Lokring, And

• Tape.

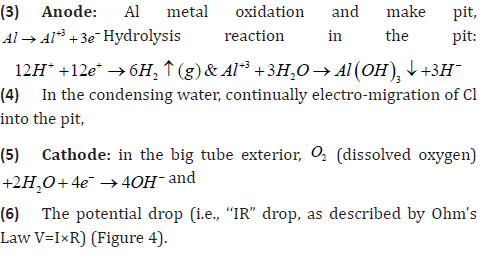

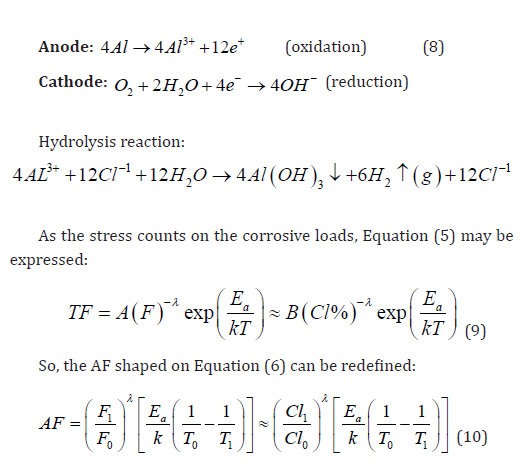

Because refrigerators cost-downed are required in the market, the newly devised aluminum (1070 Al) tubing in the enclosure was embraced and redevised from the earliest copper tubing (Figure 2). From the market, as corrosive load is repeatedly exposed, some components in the cooling enclosure had been pitting because of not revealed system defects. As an outcome, customer appeals the troublesome product to replace it. To function it for expected lifetime, the design defects of cooling enclosure in the refrigerator might be recognized and altered by parametric ALT (Figure 3). The parts of the enclosure for Aquarius pitting/crevice corrosion cover a cathode, anode, water solution (hydrolysis), and conductor (metal). That is, they are as follows:

(1) As straightly attacked by chloride of the cotton tape, Cl− on

the tube, passive film breakdowns,

(2) At the evaporator temperature, water condensation on the

tube,

The hydrolysis reaction in the pitted crevice of aluminum metal may be expressed as:

For the refrigerator, the usual ranges of conditions range from 0–50 oC ambient temperture, 0–85% humidity and 0.2–0.24 G vibration. The life target for a compressor in the refrigerator is set to be B1 life of ten years. The compressor functions on daily on/off cycles of between 22 and 98. With system life cycles of ten years, LB, the compressor is anticipated to experience up to 357,700 use time. To rapidly replicate the pitting corrosion on the tubing, the concentration of chlorine was increased, compared with 0.35% chlorine concentration because the saline water solution. The time-to-failure cycles for pitting corrosion were raised at a stress level of 3.5% saline solution (concentration load of chlorine for ALT). For an cumulative factor, λ, of 2, AF could be computed to have 100.0 from Equation (10). To fulfil the lifetime objective – B1 life of ten years, if the shape parameter, β, was presumed to be 2.0, the mission time for eighteen samples determined from Equation (7) were 8,500 cycles. As a consequence, the annoying design of enclosure can be replicated and adjusted.

In first ALT, the refrigerators put in the 3.5% saline solution were fitted at 1130 cycles (one), 1160 cycles (two), 1680 cycles (four) (Figure 5). As the troublesome enclosure from the first ALT and the market were carefully inquired, there carefully inquired, there were constructional flaws — no contraction tube which can be protected from the chloride attack. That is, the evaporator tubing could directly contact with the cotton adhesive tape which contained chloride in polyvinyl chloride (PVC) coating. To stop the pitting of enclosure in the refrigerator, designs were modified: enlarging the length of contraction tube with a non-metallic coating that can protect the direct chloride attack, C1, from 50 mm to 200 mm; (2) altering the tape, C2, from cotton to polyethylene; (3) attaching polyethylene foam pads that can prevent galvanic corrosion, C3 (Figure 6). In 2nd ALT, because of no concerns till 4,700 cycles, the enclosure in the household refrigerator can fulfil the aimed lifetime – B1 lifetime of ten years.