Impact Factor : 0.548

- NLM ID: 101723284

- OCoLC: 999826537

- LCCN: 2017202541

Martin Murimi, Michael Cheloti*, Ingrid Wekesa, Bevin Kundu and Emmanuel Kariuki

Received: March 07, 2024; Published: March 22, 2024

*Corresponding author: Michael Cheloti, Kenya Industrial Research and Development Institute (KIRDI), Nairobi, Kenya

DOI: 10.26717/BJSTR.2024.55.008747

Industrial activities such as textile, mining, pharmaceutical, agricultural chemicals, battery production and electroplating, have severely led to ecological pollution in recent years without much mitigating measures. This study aimed to provide valuable insights into sustainable water treatment by examining the synthesis process, characterizing the resulting activated carbon, and evaluating its adsorption efficiency. The main objective was to produce activated carbon from waste Aloe vera leaves for application as an adsorbent in wastewater treatment. The process involved cleaning, drying, carbonization, and activation of the dried Aloe leaves and the resultant activated carbon characterized and tested for its adsorption capacity using methylene blue dye. Consequently, the adsorption capacity analysis and kinetic study explored the adsorption rate over time. Results from the carbonization and activation process showed that, timing influences material adsorption properties while the conversion efficiency at 19.39% and 39.05% indicates the pyrolysis phase was very effective in the conversion of Aloe vera waste to activated carbon. Additionally, adsorption coefficient at 17.1, 10.2 and 24.9 mg/g is consistent with results of kinetic study that showed complete uptake of methylene blue for duration of 2 hours. Effects of pH to the sorption phase was also done and adsorbent established to be at pH of 11.3. The study showed the potential of activated carbon from Aloe vera leaves and its applicability as an adsorbent in wastewater treatment. It is recommended that future research refine the activation conditions further, investigate diverse biomass precursors, and make a thorough economic assessment for large-scale replication through manufacturing.

Keywords: Aloe vera; Adsorption; Activation; Carbonization; Pyrolysis; Wastewater

The discharge of organic and inorganic pollutants into domestic sewage has caused worldwide concerns due to their hazardous impacts on the ecosystem and biological systems, especially in developing countries (Samaei, Gato-Trinidad, Altaee [1]). On the other hand, in this respect, biomasses produced in the agricultural and cosmetic sector, such as Aloe vera waste leaves, can be both a solution to problems in wastewater, minimize environmental negativity, and provide economic benefits by contributing to the circular economy approach of handling waste in the ecosystem. Although waste biomasses can be used for biogas, bioethanol, and biodiesel production, their complex structure makes their conversion into biofuels difficult and increases the process cost. Converting these wastes into solid products such as activated carbon is a more acceptable utilization method (Ayinla, et al. [2]). Activated carbon is a solid product with a high C content obtained from the pyrolysis reaction, also called carbonization. This product can be used in wastewater applications as an adsorbent. Given the increasing environmental concerns and urgent requirement for sustainable biomass waste management, there has been a notable focus on developing methods to utilize biomass waste without causing devastating ecological effects.

Activated carbon is known for its outstanding ability to adsorb substances and is a promising solution for wastewater treatment applications (Rafatullah, [3]). This study explores a unique approach to producing activated carbon using Aloe vera leaves biomass waste as a starting material. Aloe vera plant has been reported to have numerous health advantages and possesses distinctive characteristics beyond its medicinal applications (Kim, et al. [4]). Due to its fibrous composition and high organic content, it is a promising choice for producing activated carbon through synthesis. Extracting activated carbon from Aloe vera leaves offers both a sustainable alternative and meets the increasing need to utilize agricultural waste for productive purposes. Incorporating Aloe vera leaves into the field of activated carbon production, highlights the successful merging of environmental stewardship and technological advancement in tackling the worldwide water scarcity issue. This study aims to produce activated carbon by pyrolysis from Aloe vera leaf wastes, one of the biggest potential plant wastes in the world, as an adsorbent for wastewater treatment.

General Experimental Procedures

Aloe vera leaves were oven-dried and ground using a grinding mill. Dried leaves were then powdered well using a mortar and pestle. Carbonization was done in muffle furnace. UV/VIS spectra were recorded using a pre-Unicam SPS-150 Spectrophotometer.

Procedures: The waste Aloe vera leaves were cleaned thoroughly to remove dust and dirt then cut into small pieces followed by sun drying for 48 hour (Karnan 2016 et al) and then it was oven dried at temperatures of 500C for 4 h to eliminate water and to conserve organic components simultaneously. The dried materials were then powdered well using a mortar and pestle into tiny particles, followed by carbonization at 5000C in the absence of oxygen for one hour in a muffle furnace. The carbon obtained from the carbonization of Aloe vera was crushed into the desired particle size of 500 micrometers and then subjected to an activator, 1 M NaOH chemical, for the activation process to increase their porosity and adsorption capacity. In a typical activation process, the 1M NaOH solution (activator) and A. vera carbon materials are mixed in a weight ratio of 3:4, respectively, and air-dried at room temperature for 24 hrs. Another sample was prepared, and the activation and carbonization process were done at the same time (the Aloe vera leaves were crushed, and an activator, 1M NaOH solution, was added in the same ratios as above and carbonized at 5000C for 1 hour. Subsequently, the resulting activated carbon was washed thoroughly with deionized water until the pH of the filtrate became neutral (7) and then dried for two h in a hot air oven at 1200C.

UV-VIS Spectrophotometer Analysis: The UV-VIS spectrophotometer was set up with the wavelength at 664nm, which is the maximum absorption wavelength for methylene blue. Distilled water was used as a blank solution for baseline correction. The absorbance of each standard solution and that of the diluted samples was measured using the spectrophotometer. The absorbance values were then recorded.

The weight of samples A and B were recorded after drying, as shown in the table below (Table 1). A dark powder was obtained after the carbonization heating process. Activation was done using NaOH, and its extent of adsorption was measured using a UV-visible spectrometer (Tables 3 & 4). The weight of the carbon black was recorded as shown in the table below (Table 2). Methylene blue dye was used to test for adsorption properties of the activated charcoal (Tables 5-7). Addition of activated carbon to the MB solutions Although there was a slight color change, the measure of adsorption could not be determined by visual observation. Each sample of the three types of charcoal was measured three times, and an average value was obtained as the measurement for the charcoal type. The following tables show the values obtained from the standard solutions and each type of charcoal used (Tables 3-6). The standards were then run on a UV-Vis spectrophotometer to determine the absorbance, as recorded in the table below (Table 7). The UV-VIS was set at a wavelength of 664 meters. It was observed from the graph that the regression factor R2 was 0.9861 (Figure 8).

The study aimed to produce activated carbon from waste Aloe vera leaves for wastewater treatment, addressing environmental concerns related to the disposal of Aloe vera waste. The process involved cleaning, drying, carbonization, and activation of the dried Aloe leaves. The resulting activated carbon was then characterized and tested for its adsorption capacity using methylene blue dye. In addition to the adsorption capacity analysis, a kinetic study explored the adsorption rate over time.

a) Carbonization and Activation Process

The carbonization process at 500°C resulted in the formation of a dark powder, indicating the conversion of Aloe vera leaves into carbon. Activation was done using 1 M NaOH which significantly increased the porosity and adsorption capacity of the carbon. Two methods were employed for activation: a separate activation step and simultaneous activation and carbonization. The latter (Charcoal Type B) showed higher adsorption capacity, suggesting that the activation process timing influences the material’s adsorption properties.

b) Yield and Conversion Efficiency

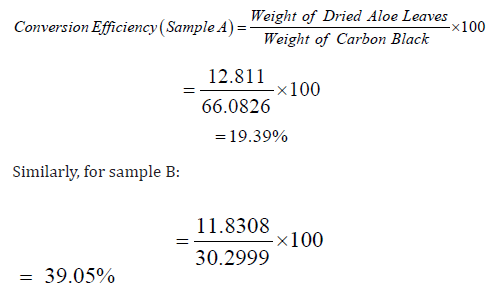

The yield calculations revealed variations in converting dry Aloe vera leaves to carbon black. Sample B showed a higher yield compared to sample A. However, challenges in sample A during the washing step after activation led to a lower yield. The conversion efficiency of Aloe vera leaves to carbon black for sample A was calculated as follows:

These results indicate that approximately 19.39% of the mass of dried Aloe vera leaves used in sample A was converted to carbon black during pyrolysis, while for sample B, it was 39.05%. These values reflect the effectiveness of the pyrolysis process in converting the Aloe vera waste into activated carbon.

c) Adsorption Capacity

Methylene blue dye was used to test the adsorption properties of the activated charcoal. The results indicated that both sample A and sample B had notable adsorption capacity, with sample B (activated and carbonized simultaneously) showing the highest adsorption. The adsorption coefficient (Ve) was calculated using the formula:

Co – initial concentration of MB

Ce – final concentration of MB

V – volume of solvent/solution

W – mass of charcoal

Substituting values for the uptake after 2 hours:

d) Kinetic Study

The kinetic adsorption studies involved monitoring the absorbance at a wavelength of 664 nm over time. The data obtained from the standard solutions and each type of charcoal were used to calculate the rate of adsorption. If you were to investigate absorption, varying with defined time rates, you would obtain the absorption coefficient against time Vt

The rate Vt was calculated using the formula:

Co – Initial concentration of MB

Ct – Final concentration of MB after time t

V – Volume of solvent/solution (200cm3)

W – Mass of charcoal

This indicates that the uptake of methylene blue at 2 hours averaged

against time is 17.1, 10.2, and 24.9, respectively.

e) Effect of Solution pH and Determination of pHpzc

Over the pH range of 2 to 12, the impact of solution pH on the sorption capacitance of MB onto the surface of activated carbon was examined. At a pH of 12, the sorption rate reached its maximum. Therefore, the pH of the solution affects the sorption process. Molecular cations are produced in aqueous by Methylene Blue (Figure 9). The pHpzc of activated carbon derived from Aloe vera wastes is displayed in the above figure. The pHpzc of the adsorbent was determined to be 11.3, as is evident.

f) UV-Visible Spectrophotometer Analysis

The UV-VIS was set at a wavelength of 664 nanometers. It was observed from the graph that the regression factor R2 was 0.9861 for the standard solution. Theoretically, the regression factor should be one since, according to Beer’s law, the absorbance of a solution is directly proportional to its concentration and the path length. As described by Beer, A=εlc the molar absorptivity was determined A/lc=ε where the ratio A/c is the gradient of the standard line we obtained. The deviation in the regression factor might be attributed to factors such as experimental error or variations in the sample preparation process. For the samples at the same wavelength of 664nm. It was observed from the graph that the regression factor R2 was 1; thus, the absorbance of a solution is directly proportional to its concentration and the path length (Figure 10).

g) Comparison with Other Studies

In this investigation, the maximum amount of Methylene blue that Aloe vera-activated Carbon could adsorb was 17.1 mg/g. The maximum sorption capacities found in other studies were compared to this value (Table 8) [5-13]. As observed, the sorbent used in this investigation had a higher Qm than other sorbents. Except for spherical carbon, the sorption occurred at very low ts toward other sorbents. In summary, activated carbon from leftover Aloe vera leaves is a highly efficient adsorbent for removing aniline from aqueous solutions (Zhang, et al. [14]).

h) Environmental and Economic Justification

The study provides a sound environmental justification for utilizing Aloe vera waste for activated carbon production. The circular economy approach, where waste materials are transformed into valuable products, minimizes waste and conserves resources, is highlighted. This aligns with the principles of sustainable and eco-friendly practices (Martini and Sharmeen Afroze, [15]). Aloe vera leaves contain valuable organic materials that, when converted into activated carbon, offer a sustainable and efficient means of resource utilization.

i) Potential Applications

The activated carbon from Aloe vera leaves demonstrated a high absorption capacity for methylene blue dye. This indicates its potential for removing various organic pollutants from wastewater and demonstrates its effectiveness in treating organic and inorganic contaminants.

Table 8: Comparison of the maximum monolayer adsorption capacity of Methylene Blue by various sorbents.

Waste Aloe vera leaves can be further be utilized for:

• Fertilizer Production: Aloe vera leaves contain various nutrients, including nitrogen, potassium, and other trace elements (BOUDREAU and BELAND, [16]). The decomposition of Aloe vera leaves can enrich the soil with these nutrients, making them valuable for organic fertilizer production. The leaves can be composted or processed into a liquid fertilizer.

• Biogas Production: When subjected to anaerobic digestion, Aloe vera waste can be a feedstock for biogas production (Nanda, [17]). Microorganisms break down the organic matter in the waste, producing biogas (methane and carbon dioxide) as a byproduct. This renewable energy source can be utilized for cooking or electricity generation.

• Animal Feed Supplement: Aloe vera leaves may be incorporated into animal feed formulations, providing supplementary nutrition for livestock. Studies have explored Aloe vera waste in cattle diets, showing potential benefits such as increased milk production and improved overall health [18].

The work showed the possibility of activated carbon from Aloe vera leaves and its applicability as an adsorbent in wastewater treatment. The larger objective behind this research was to convert Aloe vera waste into a versatile potential resource that tackles two problems: environmental challenges related to the disposal of wastes and the need for more efficient adsorbents in wastewater treatment. The results of the study showed promising findings and highlighted observations. It was established by the yield calculations that the A sample (carbonized first and later activated) resulted in 19.39%. At the same time, B, which underwent activation simultaneously with carbonization, had a figure above 37%. The research concluded that co-activation and carbonization (Charcoal Type B) resulted in the highest adsorption capacity compared to commercially available activated carbons. However, it is worth mentioning that the yield variation could be due to losses during washing primarily caused by particles passing through sieves. This indicates the optimization of the post-activation treatment process for yield improvement. In addition, the adsorption efficiency of Aloe vera-derived activated carbon was characterized using UV-Vis spectrophotometry for methylene blue dye. These findings illustrated that Charcoal Type B (simultaneously activated and carbonized) had the highest adsorption capacity, followed by Charcoal A (carbonized and then autoclaved). In contrast, commercial-grade AC revealed a relatively lower removal level. This points to the fact that production methods determine the adsorption properties of activated carbon, and simultaneous activation and carbonization are particularly efficient.

The UV-Vis analysis yielded a regression factor (R2) of 0.9861, showing a perfect fit between absorbance and concentration. Any deviation from the theoretical value can be attributed to experimental factors or different features by sample preparation. Despite this, the outcomes confirmed that Aloe vera-derived activated carbon has significant potential as an efficient wastewater adsorbent compared to its commercial counterparts. The study of the kinetic aspects in both adsorption processes is critical and provides valuable information about the phase. The adsorption coefficient (+ve) values and methylene blue uptake at various time intervals were determined, which helped to understand how fast the process was conducted. These formulae provide helpful information about Aloe vera carbon and its practical use and performance over time. This research has effectively met its goals and provided feasible outcomes, though there are other opportunities for further study. It is recommended that future research refine the activation conditions further, investigate diverse biomass precursors, and make a thorough economic assessment for large-scale manufacturing. Furthermore, a better understanding of the mechanisms governing adsorption and how activated carbon could be regenerated to make it practical for more extended periods would add significantly from this domain’s perspective. Finally, manufacturing activated carbon from Aloe vera leaves is a potential venture with various benefits. It addresses environmental issues related to waste disposal, complies with circular economy ideas by converting waste into a valuable product, and provides an ecological protection strategy that satisfies increasing requirements for effective adsorbents in wastewater treatment. Nature-based solutions have great potential to address current environmental issues, and the successful transformation of Aloe vera waste into activated carbon demonstrates the merging of tradition methods and innovation.

a) Optimization of Activation Process: Investigate the differences in activator (NaOH) concentrations and type to establish optimal conditions for activation. Perform experiments of varying activation times and temperatures to develop the ideal circumstances that give maximum porosity and adsorption capacity.

b) Surface Area Analysis: Conduct intricate characterization methods such as BET analysis to determine the activated carbon’s surface area and pore size distribution. This will lead to a better understanding of how the structural properties influence adsorption.

c) Mechanism Studies: Study the dynamics of adsorption. Perform experimental studies on the interaction mechanism between activated carbon and methylene blue dye, whether it is a case of physical adsorption or chemical bonding.

d) Real Wastewater Testing: Stop relying on synthetic dye solutions and test samples of natural wastewater. They will validate the utility of activated carbon derived from Aloe vera in actual wastewater treatment settings.

e) Scale-up Studies: Research on the scalability of production. Evaluate potential industrial applications based on batch size, processing time, and resource requirements.

f) Comparison with Other Precursors: It is suitable to compare adsorption performance with Aloe vera-derived activated carbon and other precursors-derived activated carbons. This may illuminate Aloe vera-based activated carbon’s specific peculiarities and benefits.

We wish to acknowledge the following persons: Lincoln Kiviya, Faith Jeptum, Moris Mwangi, Grace Simiyu, Shirly Bett, and Kipkorir Elvis for their collaborative efforts and playing a pivotal role in various aspects of the research study. We are indebted to the Kenya Industrial Research and Development Institute (KIRDI) for providing the laboratory infrastructure and equipment to undertake this study.

Conflicts of Interest

The authors declare that no conflict of/ competing interest exist.

Author Declarations

All authors have read and agreed to the publication of the manuscript.

Ethics Approval/Declarations

It is not applicable.

Data Availability Statement

The authors declare that the data supporting the findings of this study are available within the paper and its Supplementary information files. Should any raw data files be needed in another format they are available from the corresponding author upon reasonable request.