Impact Factor : 0.548

- NLM ID: 101723284

- OCoLC: 999826537

- LCCN: 2017202541

Seongwoo Woo1*, Dennis L Oneal2, Yimer Mohammed Hassen1, Gezae Mebrahtu1 and Hadush Tedros Alem1

Received: January 05, 2023; Published: January 11, 2024

*Corresponding author: Seongwoo Woo, Manufacturing Technology, Mechanical Technology, Ethiopian Technical University, Addis Ababa, Ethiopia

DOI: 10.26717/BJSTR.2024.54.008561

To reinforce the construction of mechanical system, parametric Accelerated Life Testing (ALT) as planned approach is proffered to quantify the mechancial lifetime constantly exposed by torque, shaped on life–stress model and sample size. This organized approach permits a designer to discern the system defects that may have an important result on reliability. Ultimately, company can stop recalls from the marketplace. As a case, the ice-maker, detaining the auger motor with gear system in a domestic refrigerator, was examined.

Keywords: Mechanical Product; Ice-Maker; Gear; Parametric Alt; Fatigue; Product Defects

The product operated by machine transfers power to detain an objective which requires motions & forces and gains mechanical advantages by accurately performing certain mechanisms. For case, by performing the vapor-compression cycle, a domestic refrigerator allows cold air from evaporator to refrigerator & freezer sections. Among numerous roles in a household refrigerator, ice-maker gathers ice and dispenses it to the cup. It consists of helix support, blade dispenser, blade helix upper dispenser, auger motor with gear system, etc. Ice-maker might be designed to properly work under the circumstances exposed by the customer who really employs it. If there are product deficiencies in the structure, ice-maker cannot unexpectedly function in its lifetime. As discovering it by Parametric ALT, a designer may design in the most desirable manner [1]. It contains:

1) An ALT plan,

2) Load inspection,

3) ALT with some rectifications, and

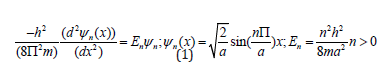

4) A judgement if system reaches to the aimed BX life. As a case inspection, the ice-maker, detaining the auger motor with gear system, shall be inspected. Parametric ALT in mechanical system Forming the solution for Schrodinger’s governing equation may be achieved:

Phenomena of linear transport may be expressed:

As an occurrence, solid-state diffusion for silicon, J, may be stated

As Equation (3) sets the reverse, the life-stress (LS) expression may be signified:

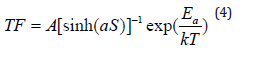

The [sinh(aS)]−1 term in Equation (4) has aspect: 1) (S)−1 in the onset has almost straight line effect, 2) (S)−n is found as a central effect, and 3) (eas)−1 is extremely large in the termination. In the central effect, an ALT is carried out. As the stress comes from effort, Equation (4) can be differently defined as:

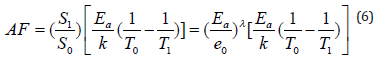

To get the acceleration factor (AF), stated as the link between the raised-level stress and normal stress, Equation (5) can be changed to combine with this assumption:

To acquire the assigned mission time, sample size formulation included with Equation (6) can be stated as [2]:

Increasing Lifetime of the Ice-Maker Constructing in Auger Motor with Gear System in a Household Refrigerator As a role of the refrigerator, customer want to employ ice-maker to give out ice. To meet these expectations, an ice-maker is designed. Distributing ice in a household refrigerator requires:

1. Ice gathering in an ice-maker system,

2. End-user pushes the cup to the dispenser lever, and

3. Ice distributes. The important structural parts have as follows: helix support1, blade dispenser2, helix upper dispenser3, blade4, and auger motor with gear system5(Figure 1). From the field, as dispenser lever is repeatedly applied, ice-maker, involving auger motors with gear system, had been cracking and fracturing because of unknown product flaws, accompanying by customers to appeal the process of returning it. To appropriately work the ice-maker for anticipated life, the design flaws in a product can be uncovered unexpectedly and changed by parametric ALT (Figure 2). From the bond graph modeling of ice-maker (Figure 3), the governing equation can be stated:

As the stress depends on the exerted torque, Equation (5) may be restated:

Therefore, the AF formed on Equation (6) may be restated:

For the ice-maker in a household refrigerator, the working (or environment) circumstances are 0–43°C and humidity spanning from 0 to 95 percent with 0.2–0.24 g’s acceleration. The period of ice-maker for each day functions from three to eighteen. Based on the lifetime for ten years, the ice-maker was accomplished to 65,700 use cycles. For the worst-case, the maximum torque uncovered to the end-user in distributing ice, T0, was 0.69 kN-cm. For ALT, the exerted torque, T1, grew to 1.47 kN-cm [2]. With an accumulative factor, λ, of 2, AF in Equation (10) was 4.0. To obtain the life aim – B1 life of ten years, if the shape parameter, b, was supposed to have 2.0, the assigned cycles for ten specimens computed in Equation (7) were 42,000 cycles. As a result, the problematic design of ice-maker may be discovered and altered. In 1st ALT, cracked and fractured gear in an auger motor of ice-maker reproduced at 6,000 cycles, 6,900 cycles, 8,500 cycles, and 8,700 cycles (Figure 4). As the cracked and fractured gear system from the 1st ALT and the marketplace were carefully examining by a stereomicroscope, there were design defects—a cast iron that may not be tolerated under the freezing temperature (−20°C ¯). That is, as the gear teeth made of cast iron repetitively hit each other, they began to crack and eventually fracture because the component was brittle under this circumstance. As action plans, the problematic material of the gear system employed in the field was modified from the cast iron (carbon, 3 wt% and silicon, 2 wt%) to the sinter-hardened powder metallurgy nickel steel. In 2nd ALT, the helix upper dispenser having the basic material of polycarbonates cracked and fractured in the contact region. To understand the basic origin of the problematic system, it was unexpectedly discovered that there were design imperfections in the structure — the weld-line between the blade dispenser and the helix upper dispenser—which was various voids established in the injection procedure. As action plans, a strengthened rib of the helix had thickened after the injection was altered. As a consequence, Finite Element Analysis (FEA), integrated with parametric ALTs result, was carried out. As a consequence, the component stress by performing FEA examination was lessened from 45.0 kPa to 20.0 kPa (Figure 5). As the designs in the structure were altered, the ice-maker in a refrigerator will acceptably carry out to achieve the targeted life – B1 life of ten years – because there were no problems until 42,000 cycles.