Impact Factor : 0.548

- NLM ID: 101723284

- OCoLC: 999826537

- LCCN: 2017202541

SM Sabrina Yesmin, Amjad Hossen, Ashis Sutradhar Nitai, Tonny Chowdhury and Md Ibrahim H Mondal*

Received: August 09, 2023; Published: August 22, 2023

*Corresponding author: Md Ibrahim H Mondal, Polymer and Textile Research Lab, Department of Applied Chemistry and Chemical Engineering, Rajshahi University, Rajshahi-6205, Bangladesh

DOI: 10.26717/BJSTR.2023.52.008247

To improve the properties of jute fibre, alkali-activated bleached jute fibre has been modified by graftcopolymerization with methyl acrylate (MA) and methyl methacrylate (MMA). The maximum graft yield and grafting efficiency at optimal conditions are 18.87% and 20.96% for MA and 23.78% and 29.73% for MMA respectively. After the modification, the thermal stability and tensile strength of the jute fabric are increased whereas moisture content and the degradation rate are decreased. This result was confirmed by TGA, DTA & DTG analyses, and heating with IR. The absorption of dye by grafted jute fibres was lower than by alkali-activated jute fibre. On prolonged exposure to sunlight in the air, the yellowing of modified jute fibre is slightly lower than that of alkali-activated bleached jute fibre. The colour fastness of dyed alkali-activated bleached and modified fibres on washing with soap solution decreases with increasing the washing temperature. The aim of the research was to modify the jute fibre and improve its physico-chemical properties and dying characteristics as well as the mechanical properties. Currently, the demand for modified jute fibres has been growing internationally because it is natural, sustainable, biodegradable, and environmentally friendly.

Keywords: Methyl Methacrylate; Methyl Acrylate; Grafting; Jute Fibre; Dyeing; Physico-Chemical Characteristics

Jute is a naturally long, soft and shiny biodegradable fiber with advantages such as high tensile strength, excellent thermal conductivity [1]. Jute fiber is a bast fiber obtained from the bark of jute plant composed of mainly cellulose, hemicellulose and lignin [2,3] that’s why it is commonly called as lignocellulosic fibre. Bangladesh, China, and India are the three major producers in the cultivation or production of jute fibre [4]. Recently, due to the development of people’s living standards and need for environmental protection, the demand of natural biodegradable and eco-friendly fibers is rising worldwide day by day and provides positive environmental advantages concerning ultimate disposability and natural feelings of the fabric [5,6]. There have many species of jute fibres. Among them, White jute (Corchorus capsularis) and Tossa jute (Corchorus olitorius) are commonly cultivated in Bangladesh [7,8]. For the last few decades, it has been facing keen competition with synthetic jute fibre. Therefore, attention is needed to find out the diversified uses of jute. Degradation is a reaction involving the rupture of chemical bonds in the main chain of the jute fibre [9]. Degradation may be divided into three types: physical, chemical, and physico-chemical degradation. On prolonged exposure to sunlight, molecular breakdown takes place causing photochemical degradation. The main features of the photochemical changes in jute are yellowing. Jute fibres combine good mechanical properties with low specific mass.

But there have some drawbacks of conventional jute fabric such as its coarseness, rigidity, photo-yellowing, poor colour fastness, poor wettability and insufficient adhesion between untreated fibre and the modified fibre [10-12]. Jute has also some inherent which seriously limit its general use, especially for textile purposes. In order to improve these limitations, different treatment strategies have been developed to fight with the synthetic products, many scientists have already carried out research from different angles [9]. Thus, the objectives of the research were to modify the unmodified or, alkali- bleached fibres and investigate the effect of the grafting of methyl acrylate and methyl methacrylate onto jute fibre. Besides, it was also an aim to improve its physico-chemical properties and dying characteristics as well as the mechanical properties. Recently, the demand for modified jute fibres is growing internationally because it is natural, sustainable, biodegradable, and environmentally friendly. The alkali- activated bleached jute fibre was chemically modified with vinyl monomers, e.g., methyl acrylate and methyl methacrylate in presence of the initiator, K2S2O8, and under the catalytic influence of FeSO4 in order to improve the textile properties. The textile characteristics of the grafted fibres, e. g. dyeing properties, tensile properties, thermal stability, moisture content, and colour fastness properties of jute fibres have been improved which was analyzed by using FTIR, TGA, DTA, and DTG analyses.

Materials

Jute fibre was collected from Rajshahi Jute Mills and required chemicals like sodium chlorite, acetic acid, potassium persulphate, ferrous sulfate, methyl acrylate, methyl methacrylate, reactive orange 14, reactive brown 10, direct blue 1, and other essential chemicals were purchased from BDH, Merck, Sigma-Aldrich, etc.

Bleaching Process

Sodium chlorite (NaClO2) seems to be a promising bleaching agent. Sodium Chlorite solution of strength 0.5% or 5% gm per litre was prepared and its pH was adjusted to 4 by adding 0.2M acetic acid solution. For each gm of jute fibre, 80 ml of the liquor was taken and bleaching was conducted at a temperature of 85-90 OC for 90 minutes in the fibre-liquor ratio of 1:50 [13]. Prior to starting bleaching 1 ml buffer solution of acetic acid and sodium acetate of pH 4 was added for every 10 ml of the liquor to maintain the constant pH through the process. Sodium acetate buffer was used to control the pH of the solution. After the completion of bleaching, the fibre was washed well with distilled water and immersed in 0.2% sodium bisulphite solution for 15 minutes, then washed with distilled water and dried in open air, and stored in a desiccator [14].

Modification Process of Jute Fibres

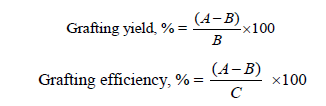

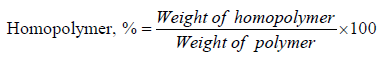

Grafting is the best method for modifying the cellulose molecule through the creation of branches that imparts certain desirable physicochemical properties to the cellulose. Jute sample was taken in a quickfit flask, and the required amount of vinyl monomers (MA & MMA) was added to the fibre (80% for both MA & MMA). Then initiator (K2S2O8) and catalyst (FeSO4.7H2O) solutions of about 5% for both MA & MMA were added to the modifying baths, where the fibre-liquor ratio was maintained at 1:30. Modification was started at 30 OC and then the temperature was slowly increased upto 60 OC within 30 minutes and continued for 90 minutes with occasional stirring by a glass rod, then allowed for further 30 minutes. During the modification period, hot distilled water was added to the modifying baths in order to maintain the fibre liquor ratio at 1:30 constant [14-16]. After modification, the fibres were then washed with hot distilled water to remove the suspended homopolymer on the jute sample and dried at room temperature. In order to select optimum conditions for modification of jute fibre, monomer concentration, initiator concentration, catalyst concentration, modification time, and modification temperature were selected accordingly to obtain maximum grafting. The percentage of grafting and grafting efficiency was calculated according to the following formulas [14,15]:

Where A is the weight of the grafted jute fibre after modification, B is the weight of ungrafted jute fibre before modification and C is the weight of the total monomer used.

Dyeing Process

Direct and reactive dyestuffs were dissolved by adding cold distilled water and the dye baths were prepared by taking the required amount of dye and electrolyte (NaCl for direct dye and Al2(SO4)3 for reactive dye). The fibre liquor ratio was maintained at 1:30. In a thermostat control water bath, dyeing was started at 90 OC for direct and 30 °C for reactive dye. For reactive dyeing, the temperature was slowly increased with occasional stirring upto 100 °C within 30 min, continued for 60 min, and then allowed for a further 30 min. During dyeing hot distilled water was added to the dyebaths and also the dye baths were slightly alkalified with 2% sodium carbonate solution for reactive dye fixation in order to maintain the fibre liquor ratio of 1:30. After dyeing the fibres were squeezed over dyebaths so that not a single drop of exhausted dye liquor was lost, rinsed with cold distilled water and dried at room temperature. The rinsed water was added to the exhausted dyebath [9,17,18].

Measurement of Breaking Strength of Jute Fibre

The breaking strength of Jute fibres was measured using the tensile strength tester (Torsees Schopper type - OS - 100). For measuring the breaking strength of jute fibre, 0.5 gm of each specimen was weighed out and clamped between the jaws of the machine. The breaking load was gradually increased after starting the machine and at a particular point, the specimen was broken down. The breaking load was shown on the scale of the tensile tester in kg. The percentage of grafting and grafting efficiency was calculated according to the following formulas [3,18]:

Where, A is the weight of the grafted jute fibre after modification, B is the weight of ungrafted jute fibre before modification and C is the weight of the total monomer used. The percent conversion to homopolymer was calculated as follows,

Determination of Moisture Content

The moisture content of the alkali-activated bleached and modified jute fibres has been measured by a Moisture Analyzer (Model: R H 120-3, Kern, Germany). The heating was done at 100°C with IR radiation in the Moisture analyzer. The temperature range of the analyzer is 0-250°C.

FTIR Analyses

For confirmation of the incorporated vinyl monomer the IR spectra of alkali-activated bleached and grafted (with MA and MMA) jute fibres were recorded by the FTIR- Spectrophotometer (Model: FTIR- 8900, Shimadzu, Japan). About 2% powder sample was mixed with KBr and IR Spectra of the sample were recorded by using KBr pellet in the range from 4000 to 400 cm-1.

TGA, DTA, DTG Analyses

The thermal stability and the degradation rate of the alkali-activated bleached and modified jute fibre were recorded with a TGA, DTA, DTG Analyzer (SEIKO- EXTAR TG/DTA- 6300, Japan). The temperature range was from 400 to 600 ℃.

To overcome or minimize some unfavourable textile properties like high stiffness, very low elasticity, susceptibility towards sunlight, etc., graft copolymerization of MA and MMA onto jute fibre has been attempted during this experiment. Obtained the maximum graft level for MA and MMA was 20.96 % and 29.73% respectively using optimal conditions of monomer concentration, initiator (K2SO8) concentration, and catalyst (FeSO4) concentration, time and temperature factors. All over things including physico-chemical and dyeing activity are explained using some test.

Physico-Chemical Property Analysis of Modified Jute Fibre Present work investigated the effect of grafting methyl acrylate and methyl methacrylate onto fibre. Here, graft co-polymerization of vinyl monomers (MA and MMA) onto bleached jute fibre initiated by potassium persulphate, K2SO8 in the presence of FeSO4 may be pictured as involving generation of macro - radical (-OH and SO4=) species and to some extent by Fe(III) ions on jute fibres. The free radical species and Fe(III) ions are produced from the redox reaction between K2SO8 and Fe(II). The macroradicals so formed subsequently attack the monomer leading to chain initiation [19]. The termination of graft co-polymerization may be due to the interaction with Fe(III) ions or mutual combination of grafted chains on different backbones. This proposed graft copolymerization mechanism is similar to the literature review [12,20,21]. After all, the textile characteristics of the grafted fibres, e. g. dyeing properties, tensile properties, thermal stability, moisture content and fastness properties of jute fibres have also been studied.

Graft yield and Grafting Efficiency

After bleaching of jute fibres with NaClO2, it was modified via graft copolymerization in presence of two vinyl monomers i.e., MA and MMA. Where, varying monomer concentration, initiator (K2S2O8) concentration, catalyst (FeSO4) concentration, modification time and temperature act as the controlling factors of graft yields and grafting efficiency, which are shown in (Figure 1). From (Figure 1a), the percent grafting of MMA is higher than that of MA at 80% and 90% monomer concentration respectively. This variation may be due to the chemical features and the presence of double bonds in vinyl monomers bestows polyfunctionality on them. In addition, MMA is more chemically reactive than that MA due to their substituent structure, which increases the reactivity of a monomer towards radical attack [13,22]. As a result, maximum graft yield and grafting efficiencies are in favour of MMA. So, based on the maximum grafting capability, their other factors like initiator concentration, temperature, time, and catalyst concentration are respectively shown in (Figures 1b-1e). From the experiments of modification (grafting), it was observed that the methyl acrylate and methyl methacrylate modified jute fibres were more lustrous, uniform and pleasant at optimum condition (5% initiator and catalyst concentration at 60 °C for 90 min duration) than alkali activated bleached jute fibre.

Tensile Strength Analysis

As a part of the physical characteristics, the relative breaking strength of jute fibres was measured by using the Tensile Strength Tester. It is observed that the breaking strength of modified jute fibres is 28.72 kg/yarn and 29.47 kg/yarn respectively for MA and MMA modified fibres and these are higher than that of alkali-activated bleached jute fibre (27.5 kg/yarn) caused due to grafting with MA and MMA, and the incorporation of monomer. This may chemically bind the cellulosic chains conferring additional strength to jute. Additionally, the breaking strength of MMA-modified jute fibre is higher than that of MA-modified jute fibre due to show rigid and soft polymeric behaviours of poly-MMA and poly-MA respectively [23].

Effect of Moisture Content

The moisture content of alkali-activated bleached jute fibre is higher, which is 16.63%, whereas that of methyl acrylate and methymethacrylate- modifieded jute fibres are 12.87% and 13.06% respectively. Due to modification with monomer (MA & MMA) hydrophobicity of the fibre increased. On the other hand, MMA-modified fibre is more hydrophilic than MA-modified fibre [24,25]. So, the moisture content of MMA-modified jute fibre is higher (13.06%) than MA-modified jute fibre (12.87%). This happened due to the modification and immiscibility of the methyl group with water.

Dye Absorption Characteristics of Dyeing

For dyeing purposes, four types of dyes (Reactive Orange 14, Reactive Brown 10, Direct Orange 31, and Direct Blue 1) under two groups of dyes (reactive and direct dyes) are chosen and used in the experiment. Results are observed that the absorption of dye by grafted jute fibres are (MMA/MA: 41.17/44.17; 41.36/46.19.00; 85/88.89; 96.15/96.77 respectively) just lower that of alkali-activated jute fibre (48.75; 47.40; 9.001; 97.67 respectively) which may be caused to the blocking of the active site of the bleached fibre by hydrophobic monomer.

Colour or Light Fastness Test

It is observed that the light fastness rating of bleached and modified jute fibres after 250 hours of exposure to sunlight in the open air is nearly the same. The modified jute fibres show slightly better light fastness, this may also be due to the low rate of moisture diffusion to the site of fading by modification. So, modification lowers the access of both moisture and oxygen which are known to participate in fading or yellowing. But, after dyeing with different dyes, observed variation in the light colour fastness with time variation. According to the grafting efficiency, tensile strength, and effect of moisture content, the MMA-modified jute fibre is better than bleached and MA-modified jute fibre. So, based on the grafting response here colour fastness was investigated on MMA-modified jute fibre after dyeing in sunlight (Table 1) and in a soap solution, where absorbed dyes hold their colour up to 80 °C in soap solution.

Note: #FG (Fastness Grade), DO (Deep Orange), DBr (Deep Brown), DB (Deep Blue), O (Orange), Br (Brown), B (Blue), LO (Light Orange), LBr (Light Brown), LB (Light Blue), FO (Fade Orange), FBr (Fade Brown), FB (Fade Blue)

FTIR, TGA, DTA and DTG Analysis

The additional peaks at 1732.0 cm-1 in the FTIR spectra of grafted jute fibre suggest and confirmed that jute fibre is grafted with the MMA monomer, where the peak observed is due to the ester carbonyl group of MMA (Figure 2). Thermal stability, thermal degradation, and reaction properties can be understood with analysis of TGA, DTA, and DTG listed in (Table 2). 7.9% loss was observed in weight up to 299°C for the MMA-modified fibres, which indicates the thermal stability increased after modification with MA and MMA, due to the incorporation of acrylate monomer onto the jute fibre. DTA curves of MMA-modified fibres show endothermic downward peaks at 77.6°C, 227.6°C and 328.3°C respectively indicating the desorption of water and removal of volatile material from the fibre. But, due to the oxidation of degradation fragments with atmospheric oxygen, a peak at 385°C shows exothermic properties [18,26]. From (Figure 3) the maximum rate of pyrolysis of MMA-modified fibers is 1.166 mg/min at 337.9°C respectively. This indicates that modified fiber degrades slowly even at high temperature than unmodified fiber.

Graft copolymerization of jute fibre was carried out with vinyl monomers (MA and MMA) with varying monomer concentration, initiator concentration, catalyst concentration, modification time, and temperature. The graft yield increased with the increase of monomer concentration up to 90% for MA and up to 80% for MMA and that’s values are countably higher to literature study e.g., 17.3% for MA and 19.4% for MMA. In its IR spectroscopic analysis of grafted jute fibre, the peak at 1733.9 cm-1 for MA and 1732.0 cm-1 for MMA have been confirmed. From the experiment of modification, it was observed that the MA and MMA modified fibres are more lustrous, uniform, and pleasant in appearance than bleached jute fibre. The moisture absorption capacity of modified fibre decreased than unmodified alkali- activated bleached fibre. Bleached alkali-activated fibre is thermally stable than the unmodified fire and more thermally stable till 301.1°C. So, the breaking strength of modified fibre also improved. In the case of dyeing, the percentage of dye absorption of modified fibre slightly decreased than unmodified fibre. The color of dyed fibres also fades on exposure to sunlight and washing with the soap solution. But modified jute fibres show slightly better fastness than unmodified jute fibres. Thus, the modified fibre with MMA and MA shows improved textile performance.