Impact Factor : 0.548

- NLM ID: 101723284

- OCoLC: 999826537

- LCCN: 2017202541

Dmitriy A Fedorishin1,2, Altynaray T Takibayeva1, Abdigali A Bakibaev1,2, Olga V Demets1*, Maria V Lyapunova1,2, Madina R Aliyeva4, Rymkhan Kassenov4, Irina A Kurzina1,2, Elena A Mamaeva1,3 and Saule B Akhmetova5

Received: March 14, 2023; Published: March 29, 2023

*Corresponding author: Olga V Demets, Department of Chemistry and Chemical Technologies, NJSC Karaganda Technical University Named after Abylkas Saginov, Karaganda, Kazakhstan

DOI: 10.26717/BJSTR.2023.49.007808

The concomitant risk of the inflammatory process could be observed in the treating of burns and wounds. Thus, the search of the effective and nontoxic drugs to treat the infected wounds is a current objective for scientists.

A group of authors have obtained a composite biomaterial based on betulin and glycoluril. It was a solid dosage form. The obtained sample has been studied on the mechanical tensile strength. Its antibacterial activity and cytotoxicity have been examined. The research results have demonstrated that the composite biomaerial had the antibacterial activity against E. coli. An optimal sample of the composite biomaterial has been found with the highest strength index.

Keywords: Betulin; Glycoluryl; Sodium Salt of Carboxymethyl Cellulose; Biomaterial; Physico Mechanical Prop Erties; Films; Cytotoxicity; Antibacterial Activity

The World Health Organization affirms that burns and injuries are a global public health problem. An estimated 180 000 deaths annually are caused by this type of injury all over the world [1]. Currently, the problem of the healing skin disorders is very relevant for the regenerative medicine. The wound treatment has a concomitant risk to develop an inflammatory response. This response can impede the natural wound healing process and cause the various complications. Such complications include the poor tissue injury recovery and maturation which lead to the high material costs to treat. Probability of fatality is also high. The literature sources have described that the surgical procedures are followed by the purulent complications, and their proportion - 28-34%. Lethality caused by maturation of the postoperative sutures is 22% [2]. In order to treat wounds, creams and ointments are used for injured body part. These medicinal creams have been creating on the basis of bioresorbable materials. They contain therapeutic agents such as enzymes, anesthetics and antibiotics in order to have a complex effect on wound healing [3-5]. A problem is to choose the optimal wound dressing or their effective combinations with the physiotherapeutic methods to treat the local superficial and deep wounds, and to select the wound infection prevention [6,7]. The maximum wound-healing effect of these drugs has not yet been developed [8]. The natural substances having the antimicrobial and antiviral activities are of great interest.

The authors of this article have developed the composition of a composite biomaterial based on betulin in the form of a solid dosage form for the treatment of wounds and burns. Its components were betulin, miramistin, glycoluril and sodium salt of carboxymethyl cellulose. Betulin is a natural pentacyclic lupane-type triterpenoid with the proven antimicrobial and antiviral properties. Betulin has the sufficient raw material base and a broad spectrum biological activity. Consequently, it is the valuable natural source, and it may be used in its native state and in form of the various transformation products or as part of composition [9]. In the resulting composite biomaterial composition, the glycoluril is applied as a crosslinking agent [10]. The thick film coating has been observed after the drying of the composite biomaterial. Another adjuvant is a sodium salt of carboxymethyl cellulose. It is able to increase the viscosity of fluid and stabilize suspensions of the solid particles in the liquid. This substance has no risk of mutagenicity or carcinogenicity [11-13]. The CMC-Na has been used as a thickening and gelling agent in the composition of the obtained biomaterial. The resulting composite material was studied for mechanical properties, antibacterial activity and cytotoxicity.

Miramistin had an adjuvant effect [14]. These properties have led to select miramistin as the second main component of the composite biomaterial.

Results on the Mechanical Tests of Composite Biomaterial Samples

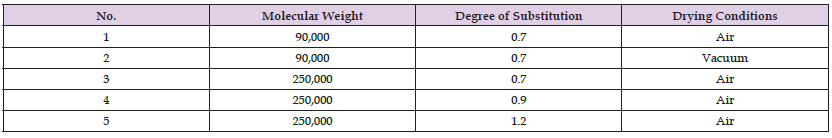

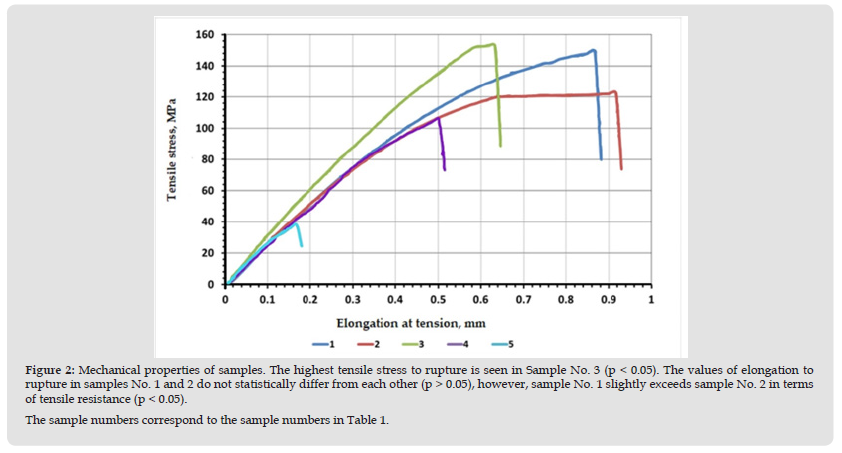

One of the research objectives was to select some adjuvants for the composite biomaterial. CMC-Na is commercially available in various degrees of substitution. The aim of the physical-mechanical tests of the composite biomaterial samples was to study the effect of the degree of substitution and the CMC-Na molecular weight on the mechanical film strength. These films have been formed after the drying of composite biomaterial. As a result, 5 samples with CMC-Na included in their composition with different molecular weights and degrees of substitution have been developed. Each sample has been carefully placed on the Petri dish. After the drying of each sample, a polymer film has been carefully peeled out the Petri dish bottom and cut into the equal rectangular strips. Then the obtained strips have been tested on a tensile testing machine. These tests have determined differences in the mechanical properties of the obtained samples of No. 1-5. The measurement has demonstrated that sample No. 5 had the worst strength and the elastic characteristics. In contrast, samples of No. 1 and 2 had the best strength and elastic characteristics of all the samples (Table 1 & Figure 1). Thus, it could be concluded that samples of No. 3 and No. 4 had less strain capacity than samples of No.1 and No. 2 had. The total tensile strain before rupture of samples of No. 1 and No. 2 was 0.87 and 0.92 mm, respectively, while sample No. 5 was 0.18 mm (p < 0.05).

Table 1: The composite films based on betulin depending on degree of substitution and molecular weight of CMC-Na

Figure 2 Mechanical properties of samples. The highest tensile stress to rupture is seen in Sample No. 3 (p < 0.05). The values of elongation to rupture in samples No. 1 and 2 do not statistically differ from each other (p > 0.05), however, sample No. 1 slightly exceeds sample No. 2 in terms of tensile resistance (p < 0.05). The sample numbers correspond to the sample numbers in Table 1.

It might be stated that the elongation values before rupture in samples of No.1 and No. 2 did not statistically differ from each other (p > 0.05), but sample No. 1 exceeded sample No 2 in the tensile strength value (p < 0.05). The strength to break sample No. 3 was higher (p < 0.05) than for other samples. However, the strength to break sample No. 5 was less than for the others (p < 0.001). The (Figure 2) have illustrated that the mechanical tests determined a correlation between the degree of CMC-Na substitution and the strength sample characteristics. The film samples containing CMCNa with a degree of substitution of 0.7 had the highest strength characteristics. These samples were characterized by the highest elongation and averaged elastic modulus. It has been found that the low degree of CMC-Na substitution led to the higher film tensile strength. The physical and mechanical properties of the solid dosage forms to treat the infected wounds are a significant characteristic of their technical and medical value. Hence, in order to determine these properties is the most important test. Thus, each solid dosage form should be tested. The usability of the obtained films for the wound therapy has directly depended on their mechanical properties: load, duration of their action, the environmental humidity and other factors. The effect of these parameters on usability of the wound dressings should be included to select the adjuvant structural substances for their manufacture. The physical and mechanical tests have determined the tensile strength and strain. The studied samples were films consisting of the biologically active organic substances. In order to prepare samples, the component solution of sample No. 2 has been under the vacuum degassing. Thus, a value of the total strain before rupture has been slight increased. However, the statistically significant differences have not been found between sample No. 2 and No. 1. The vacuum degassing has not used for these samples. In this regard, we considered the use of vacuum to be inexpedient and economically unprofitable.

Investigation of Antibacterial Activity

The antibacterial activity of films obtained by drying of the composite biomaterial samples has been examined with using a modified well-diffusion method. The studied ABD sample (composite material sample without miramistin) (Figure 1) has demonstrated the antibacterial activity against gram-negative microflora (Escherichia coli). In addition, the activity sample level against gram-negative microflora has not differed from the control (p > 0.05). The activity has not been found against gram-positive microflora (Staphylococcus aureus). The inhibition zones have not been observed. The figure has illustrated that the antibacterial activity of the ABD sample has not differed from the control (p > 0.05). The inhibition zones of Escherichia coli growth have averaged 14.3 mm for the sample dosage form (ABD), and 14.1 mm for the 10 mg/ml aqueous solution of the miramistin substance. The value for the ABD sample is higher than for the control sample. It could be stated that very urgent problem is to constantly introduce the new antibacterial drugs into the clinical practice, and also lack of literature data on effectiveness of the full range of the modern antibiotics used in medicine [15]. The microbial resistance to antibiotics has been constantly increasing and varying from year to year. As a result, it might be hypothesized that a studied strain of Staphylococcus aureus has developed resistance to miramistin.

The extraneous microflora has not been defined on the nutrient medium. The entire lawn and colonies have been attributed to the test objects by the morphological features.

Investigation on Cytotoxicity of the Composite Biomaterial

This investigation has examined the cytotoxicity of some composite sample biomaterials by the MTT test. A sample of the composite biomaterial has been used as a positive control without the ABD miramistin. The standard complete nutrient medium for this cell line has been applied as a negative control (CM). And a sample with ABD+ MRM miramistin in its composition has been also utilized. The experiment has included the sample solutions in the complete nutrient medium with concentrations of 7 mg/mL; 0.7 mg/ml; 0.07 mg/mL; 0.007 mg/mL; 0.0007 mg/mL; 0.00007 mg/mL and 0.000007 mg/ mL. The incubation duration of the fibroblast culture with the sample was 48 h, 72 h and 120 h. As a result, this experiment has found that the studied sample of ABD+MRM composite biomaterial had cytotoxicity (Figure 3). Its cytotoxicity has been defined to be higher than complete nutrient media (p < 0.05). The effect has been observed at a sample concentration of 7 mg/mL. If the number of live cells in the negative control sample was taken as 100%, the sample should reduce their number by 50%. In contrast, the ABD positive control sample in the working concentration has showed the absence of any cytotoxicity and a significant increase in the fibroblast proliferation. Thus, it could be determined by an increase in the optical density by 90% (Figure 3). It has been confirmed statistically (p < 0.05). It should be pointed out that the effect was observed in a sample concentration of 7 mg/mL. The increase of proliferation in other concentrations has not differed from the control.

It has been determined that the greatest effects of both samples have been recorded at incubation for 48 h. Many dead cells have been found in all cultures at incubation for 72 h. All results have not differed from the negative control (p > 0.05) at incubation for 120 h. The higher effects of both samples of (СМ at 7 mg/mL ) and the positive control sample (ABD) have been determined at incubation for 48h. A complete medium has been used as a negative control. A sample of the same composition without miramistin has been applied as a positive control. The sample (ABD+MRM) has been shown to be cytotoxic (p < 0.05). In contrast, the positive control sample (ABD) had no cytotoxicity and increased the fibroblast proliferation (p < 0.05). Thus, the experiment has determined that the sample dosage form (ABD+ MRM) with miramistin had cytotoxicity against fibroblasts. However, a sample (ABD) of a similar composition without miramistin has accelerated the fibroblast proliferation. The literature data have described that betulin in a dosage form had the regenerative properties, directly affecting on the fibroblast proliferation and indirectly on collagen synthesis [16-18]. It might be stated that miramistin had a toxic effect on fibroblasts. Thus, the use of miramistin causes the slower reparation processes for the damaged tissues. Thus, the research results have demonstrated that inclusion of miramistin in the sample dosage form led to an increase in its toxicity.

Extraction of Betulin from Birch Bark

The microwave activation method has been used to isolate betulin from birch bark [19-20]. Extraction has been performed in a microwave oven. The birch bark has been extracted by 20% sodium hydroxide solution with butanol. The reaction mixture has been placed in a microwave reactor for 9 min. Then a reaction mixture has been filtered from the non-hydrolyzed birch bark residue on the Büchner funnel. The raw betulin has been precipitated with an aqueous-alcoholic mixture, separated by filtration and dried to a constant weight in a drying chamber at 60°C. The product has been recrystallized in isopropanol (m.p. of 243°C). The yield of betulin was 18%.

Synthesis of Glycoluril

This investigation has showed that the synthesis of glycoluril has been performed by reaction of glyoxal and urea with using the sulfuric acid as a catalyst. The application of this method has provided conditions where the urea did not decompose [21]. In order to obtain glycoluril, 300 g (5 mol) of urea and 300g of water have been loaded into a 1 L three-neck flask equipped with a stirrer, a dropping funnel and a reflux condenser. After dissolution of urea with the constant stirring, 27 ml (0.5 mol) of the concentrated sulfuric acid (d = 1.84; C = 98%) and 290 g (2 mol) of 40% aqueous glyoxal solution have been added. Then the reaction mixture has been heated to boiling and boiled for 20min. Thereafter the reaction mixture has been cooled to a room temperature. The residue has been filtered by the vacuum filtration, washed with 300 mL water and dried at a room temperature. The result was 242 g of the white crystalline powder. The product yield was 85%.

The Obtaining of Film Materials

The composite film materials have been prepared from aqueous solutions of glycoluril. Their purity was less 99.0%. The percent concentrations were 0.01 and 0.05 with using the following technology. At the first stage, 500 g of a 0.5% solution have been prepared by adding a sample (2.5g) weighed on an A&D HR-250AZG analytical balance (A&D SCALES Co., LTD, Tokyo, Japan) to 500 ml volumetric flask and brought to the mark with distilled water. The 0.5% aqueous solution has been further diluted to concentrations of 0.01 and 0.05 wt % in 45 ml glass weighing bottle (KSH 34/12) to obtain a total mass of each solution of 40 g. At the second stage, to 0.2 g of a film-forming compound Na-CMC with the appropriate molecular weight and degree of substitution (Acros Organics BVBA, Belgium), the 1 ml of miramistin at a concentration of 10 mg/ml, an aqueous solution of glycoluril at a concentration of 0.01 wt. % and 0.5% water-alcohol solution of betulin up to a total solution weight of 10 g have been added, and then solutions have been homogenized at room temperature for 30 min with using an IKA RCT basic magnetic stirrer (IKA-Werke GmbH & Co. KG, Staufen, Germany) equipped with a built-in temperature controller at 25°C. The solutions have been placed into Petri dishes CHBN-2 (100×20 mm by GOST 23932-90) and dried in a vacuum drying chamber LT-VO/50 (Labtech LLC, Moscow, Russia) for 8 h at 25°C and a residual pressure no more 50 mbar with using a Buchi V-710 vacuum pump equipped with a vacuum controller (BUCHI Labortechnik AG, Flawil, Switzerland).

Investigation on the Physical and Mechanical Properties of Film Materials

In order to study the physical and mechanical properties of the composite biomaterial samples, an Instron 3347 tensile machine has been used. Five samples have been tested with CMC-Na of different molecular weight and degree of substitution. After drying of the composition, the obtained polymer film has been carefully separated from the Petri dish bottom and cut into rectangles of 50 mm long and 30 mm wide. The geometric dimensions of the samples have been measured to an accuracy of 0.1 mm. Thickness of each sample has been measured on three points with using a digital micrometer, and its accuracy was 0.01 mm.

• A composition of the biomaterial based on bеtulin as a solid dosage form to treat the infected wounds and burns has been developed.

• As a result, the physical and mechanical tests for films with CMC-Na having the different molecular weight and degree of substitution have found that the sample containing CMCNa with degree of substitution (0.9) and molecular weight (250000 g/mol.) had the highest strength.

• The investigation on the antibacterial activity of the composite biomaterial has shown that it had antibacterial activity against Escherichia coli.

• The studied sample of composite biomaterial containing miramistin had cytotoxicity.

• However, a similar sample of the composite biomaterial without miramistin had no cytotoxicity and has accelerated the fibroblast proliferation increasing their number in culture by 90% compared to the negative control.

A.T.T., I.A.K. and E.A.M. developed the concept of the work. A.A.B. wrote the review. D.A.F., O.V.D., M.R.A., M.V.L. and S.B.A. were engaged in an applied type of scientific activity. All authors have read and agreed to the published version of the manuscript.

This research was funded by the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan» (Grant No. АР AP08856688-OT-22 Development of methods for the extraction of natural triterpenoids from plants and their chemical transformation in order to investigate for new biologically active substances).

Not applicable.

Not applicable.

Not applicable.

The authors declare no conflict of interest.

Not applicable.