Impact Factor : 0.548

- NLM ID: 101723284

- OCoLC: 999826537

- LCCN: 2017202541

Zeynu Shamil Awol*, Rezika Tofike Abate, Gebre Egnet Biraro and Getu Weyya

Received: August 19, 2022; Published: September 06, 2022

*Corresponding author: Zeynu Shamil, Department of Chemical Engineering, Wolkite University College of Engineering &Technology College (CET), Ethiopia

DOI: 10.26717/BJSTR.2022.46.007281

Backgrounds: Plastic waste accumulating in the environment is posing an ever- increasing ecological threat. Plastics that are biodegradable can be considered environmentally friendly, they have an increasing range of potential applications and are driven by the growing use of plastics in packaging.

Results: In this study, the biodegradation of polythene pot shatter was analyzed for one month of incubation in the liquid culture method, measuring weight lost with a two-day interval up to one month. Microbial counts in the degrading materials were recorded up to 0.0278×109 per gram for total heterotrophic bacteria. The efficacy of microbes in the degradation of plastics was analyzed in the liquid (shaker) culture method. Among the bacteria and fungi strain collected from Ethiopia biodiversity institute aspergillus tubingensis strain of fungi were degrades plastic more in one month (30% of weight were loss/month) compared to others and lowest degradation rate were observed in Bacillus subtilis strain of bacteria which is (20% of weight were loss/month).

Conclusion: This work reveals that aspergillus tubingensis possesses greater potential to degrade plastics when compared with other bacteria and fungi strains. Therefore, are environmentally friendly.

Keywords: Plastics; Degradation; Microbial Species; Gram Strain; Aspergillus Tubingensis; Bacillus Subtilis

Plastics are defined as chained or linear solid polymers which on heating become mobile or extended and can be cast into moulds [1,2]. They are non-metallic moldable compounds and the materials that are made from them can be pushed into any desired shape and size [3]. Commonly, polythene plastics are delivered for different purposes, including packaging, disposable diaper backing, agricultural films and fishing nets [3,4]. Infrastructure such as agriculture, telecommunication, building and construction, consumer goods, packaging, health and medical are all high growth areas that ensure the present demand for plastics [5,6]. Plastic is the mother industry, to hundreds of components and products that are manufactured and used in our daily life, like automobile parts, electrical goods, plastic furniture, defense materials, agricultural pipes, packages and sanitary wares, pipes and fittings, tiles and flooring, artificial, leather, bottles and jars, PVC shoes and sleepers hundreds of household items [7,8]. Plastics are used in the packaging of products such as food, pharmaceuticals, cosmetics, detergents and chemicals [9].

The organized sector produces quality products whereas the unorganized sector is not capable of producing quality products [9-11]. It produces less quality, low-expensive products through excessive use of polythene plastics scrap [4]. Almost invariably, organic polythene mainly comprises plastics pots [12,13]. The majority of these polymers are based on chains of carbon atoms alone or with sulfur, oxygen or nitrogen as well [14]. The backbone is the part of the chain on the main “path” linking a large number of repeated unit’s together [15,16]. There are 2 types of plastics: thermoplastics and thermosetting plastics [3]. Thermoplastics are polythene plastics that do not undergo chemical changes in their composition when heating is applied on them and can be shaped again [17]. Thermosets are assumed to have a lot of molecular weight [18]. Thermosets can melt and can be molded into various shapes [19]. After they are solidified, they remain solid. In the thermosetting process, a chemical reaction occurs which is irreversible [13]. Vulcanization of rubber is a thermosetting process [15]. The poly isoprene is a tacky, slightly runny material before heating with sulfur, but after vulcanization the product is rigid and non-tacky [6]. Other classifications are based on qualities that are relevant for manufacturing or product design [19]. Biodegradable polymers are designed to degrade upon disposing by the action of microorganisms [1]. Microbial degradation of plastics is caused by enzymatic activities that lead to a chain cleavage of the polymer into monomers [8].

Microorganisms utilize polythene film as a sole source of carbon, resulting in partial degradation of plastics [14]. They colonized on the surface of the polyethylene plastic films, forming a biofilm [10]. Cell surface hydrophobicity of these microorganisms was found to be an important factor in the formation of biofilm on the polythene plastic surface, which consequently enhances biodegradation of the polyethene polymer [9]. Once the microorganism gets attached to the surface, it starts growing using the polythene polymer as the carbon source [16]. In primary degradation, the main chain cleaves, leading to the formation of low-molecular weight fragments (oligomers), dimers or monomers [1]. The biodegradation is due to the extra cellular enzymes secreted by the microorganisms [19]. These less molecular weight compounds are further utilized by the microorganisms as carbon and energy sources [7]. The resultant breakdown fragments must be completely used by the microorganisms, otherwise there is the potential for environmental and health consequences [18]. The purpose of this study was to isolate microorganisms from dumped soil area and the potential polyethylene degrading microorganisms and identifying the high potential microorganisms that degrade plastics [16].

Different strains of microbes were isolated by the Ethiopian biodiversity institute from different environmental sample, so we collected three strains of microbes from their microbial bank, namely Aspergillus tubingensis, Bacillus subtilis fungi and bacterial strains respectively [20-27].

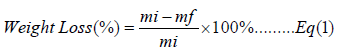

100 grams of polythene plastic pot shatter were weighed, and then aseptically transferred to a conical flask containing 150-250 ml of culture broth medium, inoculated with different microorganisms. Controlled with plastic discs in the free microbe medium, Different flasks were controlled for each treatment and left in a magmatic shaker. After a 2-day interval, we measured the mass reduction of plastics after 30 days of magnetic shaking. The polythene plastic shatter discs were gathered, cleaned thoroughly using distilled water, shade-dried and then finally weighed. From the data gathered, the mass reduction of the polythene was calculated.

Where Mi=mass of plastics before microbial inoculation

Mf = mass of plastics after final degradation

%=percent

This investigation has focused on the major concerns about the natural and fabricated Polythene plastics, their types, uses and degradability behavior. Also analyzed, it has also looked at the disposal methods and the standards used in assessing Polythene plastics degradation. Another area examined has been the biodegradation of polymers by the liquid culture inoculation method. It is clear that most recalcitrant polyethene can be degraded to some extent in the proper environment at the optimum concentration. The present funding deals with the degradative ability of Polythene to degrade microbes from soil composition. Various types of changes are adapted by microbes. Fabricated Polythene samples gathered from the soil of the wolkite university specialized hospital garden were used in the Ethiopian biodiversity institute as environmental samples we had taken from their microbial bank. These Polythene plastics were used to investigate their degradation by microbes isolated from them. Microbial degradation of a solid Polythene plastic requires the formation of a film on the Polythene plastic surface to allow the microorganisms to efficiently used the insoluble substance through biological degradation activities.

Implementation of multicellular microorganism communities binding to the surface of fabricated solid wastes has been found to be an effective biodegrading agent. When the total degradation of any organic substrate is considered, the formation of microorganism colonies is critical to the initiation of degradation. Thus, the period of microorganism colony is an important factor that affects the total biodegradation period. Microorganism counts in the biodegrading materials were observed up to 0.0278×109 per gram for total microbes those indicate that microbes grow effectively by using microbes as substrate. The microorganism strain found associated with the biodegrading plastics were identified as 2 Gram +ve and 5 Gram -ve microbes. In the current finding, shatters of Polythene plastics were inoculated in the liquid medium broth including microbes identified from Ethiopian biodiversity institutes and waited for 30 days to observe the redaction of mass by microbial strain. The result addressed the biodegradative potential of the microbes after 30 days of microbial incubation. The % of mass reduction due to biodegradation was observed more by Aspergillus tubingensis strain of fungi. This indicates that it has a powerful potential for biodegradation compared to other microbes.

This programme has the following three major functions: It identifies an unknown isolate, selects additional tests in order to distinguish between possible strains if identification is not achieved and the storage and retrieval of results. The program makes use of Excel (2007) files to store identification matrices. The program is designed to use probabilistic identification matrices that have either been published in the literature or created by the user. The bacteria which are identified from the above biochemical tests are Bacillus Subtilis (strain- 1), Bacillus Amylolyticus (strain-2) and Arthobacter defluvii (strain-3) by the software PIBWIN (Probabilistic identification of bacteria). These three bacterial species were also found on the basis of common morphological characteristics.

The microbes collected from Ethiopian biodiversity institute were Aspergillus tubingensis (fungi), Bacillus Subtilis (bacteria) were most potentially degrading plastic material other than that of other bacteria and fungi strain. Bacillus subtilis has less capacity to degrade plastic as compared to Aspergillus tubingensis fungi strain. And the isolated microbes were native to the site of polyethylene disposal and showed some degradability in natural conditions, yet they also exhibited biodegradation in laboratory conditions on synthetic media.

I would like to thank Dr. Gebre Egnet Lecture and chairs Chemical engineering in Wolkite (WKU) for his valuable guidance, advice, encouragement, support and critical comments during my research work.

Zeynu Shamil shared the drafting and planning for the project work for future, experiment fabrication and implementation, data gathering, analysis and writing the manuscript, Rezika Tofike. She guided all over the experimental work and field, gatu weyya for result analysis, and finally Dr. Gebre Egnet was advised about all experiments and manuscript writing.

There is no funding for this manuscript.

We declared and authenticated that the data and materials used in this manuscript can be made available as per the editorial policy of the journal.

Not applicable to this manuscript.

The authors declared that there is no competing interest.