ANNOTATION

Currently, amaranth grain and its processing products are widely used in the Russian Federation as vegetable raw materials for the food, oil extraction and pharmaceutical industries. Amaranth grain has a valuable chemical composition, incl. high content of the most important essential amino acid - lysine, high nutritional and biological value and is a promising raw material for use in various sectors of the food and processing industry. A technology for obtaining amaranth flakes from amaranth grain has been developed. The optimal parameters of hydrothermal treatment by the method of cold conditioning of amaranth grain in the production of flakes were determined, which amounted to moistening the original amaranth grain to a moisture content of 12-13% and annealing for 2-3 hours. The optimal value of the roll gap is set equal to 0.1 mm, at which the output of amaranth flakes can be up to 88.9% in one pass through the roll machine.

Keywords: Amaranth; Processing; Roll Gap; Amaranth Flakes

Introduction

Currently, amaranth grain and its processing products are widely used in the Russian Federation as vegetable raw materials for the food, oil extraction and pharmaceutical industries. Amaranth grain has a valuable chemical composition, incl. high content of the most important essential amino acid - lysine, high nutritional and biological value and is a promising raw material for use in various branches of the food and processing industry [1,2]. Over the past 20-30 years, unfavorable changes have occurred in the nutritional structure of the population of the Russian Federation, as a result of which the consumption of complete proteins of animal origin has decreased by 25%, the total caloric content of the diet - by 15%, the consumption of animal fats - by 70% and proteins of plant origin - by 30% [1]. At the same time, a new source of raw materials for the food industry has appeared on the world market - amaranth grain and its processing products, which have a valuable chemical composition, high nutritional and biological value, containing a wide range of physiologically functional nutrients, which determines the prospects for their use in food technology. productions [1].

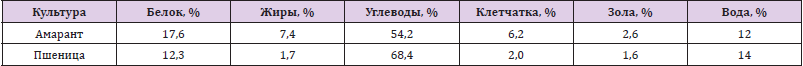

Amaranth grain processing products contain essential amino acids, insoluble dietary fiber, PP vitamins, minerals balanced in the content of Ca and P macronutrients. Analysis of various literary sources shows the advisability of using amaranth processed products as an enriching additive in various food products [1- 14, 15-23]. I would especially like to note that amaranth meal contains a unique substance - squalene, which is a strong (effective) antioxidant [5]. Recently, amaranth grain and its processing products have found wide application in the domestic market as a new vegetable source of raw materials for the food, oil extraction and pharmaceutical industries. Amaranth grain has a valuable chemical composition, incl. high content of the most important essential amino acid - lysine, high nutritional and biological value and is a promising raw material for use in various sectors of the food and processing industry [1-2]. Amaranth surpasses many traditional cereals in terms of protein, amino acids, vitamins, macroand microelements, biologically active substances and fat content, incl. wheat and rye [3]. Table 1 shows a comparative characteristic of the content of the main components in the grain of amaranth and wheat. The purpose of our research is to determine the effect of the roll gap on the output of amaranth flakes.

Objects and Methods of Research

As an object of research, we used amaranth grain of the “Voronezh” variety. The processing of amaranth grain into various products was carried out on MLP-4 laboratory grinding mills with smooth microrough rollers. The main mechanical and kinematic indicators of the MLP-4 mill with smooth microrough rollers are as follows: productivity - up to 100 kg / h, speed of the fast-rotating roller 4.5 m / s, differential 1.75.

Result and Discussion

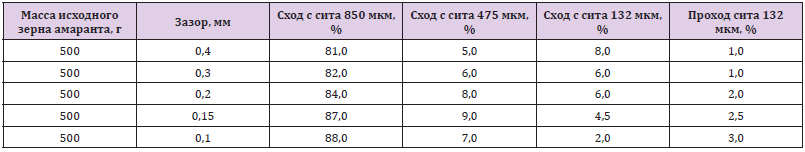

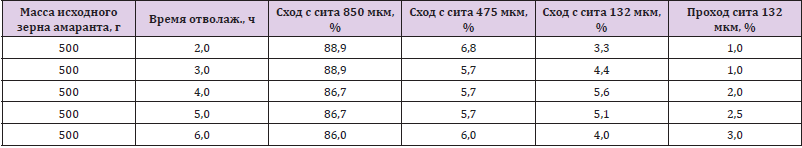

At the first stage, studies were carried out to determine the optimal roll gap to obtain the maximum yield of amaranth flakes in one pass from the original amaranth grain that underwent hydrothermal treatment (HTT) with heating for 1.5 hours. Cold conditioning was used as a TRP as the most common method. To obtain amaranth flakes, the original samples of amaranth grain were flattened in a laboratory mill MLP-4 with smooth microrough rollers with various inter-roller gaps. The data obtained are presented in Table 2 and Figure 1. At the second stage, studies were carried out to determine the effect of the time of heating on the yield of amaranth flakes. For this, the original amaranth grain was moistened to 12.2% and heated for 2.0, 3.0, 4.0, 5.0 and 6.0 hours, respectively. The obtained results of the influence of the time of heating on the yield of amaranth flakes are presented in Table 3 and Figure 2. Studies carried out at the Department of Grain, Bakery and Confectionery Technologies of the FSBEI VO “MGUPP” showed that with an optimal roll gap of 0.1 mm, the yield of amaranth flakes can be up to 88.9% per pass through a roll machine with smooth, micro-rough rollers.

Figure 1: Appearance of amaranth flakes, depending on the size roller gap (a - gap = 0.3 mm, b - gap = 0.2 mm, c - gap = 0.15 mm, d - gap = 0.10 mm).

Conclusion

A technology for obtaining amaranth flakes from amaranth grain has been developed. The optimal parameters of hydrothermal treatment by the method of cold conditioning of amaranth grain in the production of flakes were determined, which amounted to moistening the original amaranth grain to a moisture content of 12- 13% and annealing for 2-3 hours. The optimal value of the roll gap is set equal to 0.1 mm, at which the output of amaranth flakes can be up to 88.9% in one pass through the roll machine.

Conflict of Interest

The authors declare that there is no conflict of interest.

References

- Litvinova OS (2016) Structure of nutrition of the population of the Russian Federation. Hygienic assessment. Public health and habitat 5(278): 11-14.

- Zheleznov, AV, Zheleznova, NB, Burmakina, NV, Yudina (2009) RS Amaranth: scientific bases of introduction. Novosibirsk: 236 p.

- Dergausov VI (2006) Amaranth - a promising culture. Oils and fats 2: 7-9.

- Kretov IT, IT Kretov, SN Sobolev, LA Miroshnichenko, IM Zharkova (2006) Oil from amaranth seeds. Oil and fat industry 1: 22-23.

- Klyuchkin VV (1997) Main directions of processing and use of food products from lupine and amaranth seeds. Storage and processing of agricultural raw materials 9: 30-33.

- Roslyakov Yu F, NA Shmalko, LA Bochkova (2004) Prospects for the use of amaranth in the food industry. News of higher educational institutions. Technical science 4: 92-95.

- Zharkova IM, SV Lavrov, AA Samokhvalov, AV Grebenshchikov, LA Miroshnichenko (2019) Development of functional food products for gluten-free and gerodic nutrition, including for the prevention of osteoporosis. Khleboprodukty 12: 53-55.

- Officers EN (2001-2002) Amarant - promising raw materials for the food and pharmaceutical industries. Chemistry and Computer Simulation. Butlerov messages 2(5-8): 1-4.

- Shmalko NA, I I Uvarova, Yu F Roslyakov (2004) Amaranth flour - an antioxidant additive for pasta enriched with beta-carotene. Food technology 5-6: 39-41.

- Shcherbakova SA (2002) Amaranth polyphenols as natural antioxidants for fermented milk products. Dairy industry 8: 43-44.

- Kelawala NS (2004) Ananthanarayan L. Antioxidant activity of selected foodstuffs. Int J Food Sci Nutr 55(6): 511-516.

- Khandaker L, Ali MB, Oba S (2008) Total polyphenol and antioxidant activity of red amaranth (Amaranthus tricolor ) as affected by different sunlight level. J Jap Soc Hort Sci 77(4): 395-401.

- Gins MS, Gins Vol K, Kononkov PF (2002) Change in the biochemical composition of amaranth leaves during selection for increased amaranthine content. Appl Biochem Microbiol 38 (5): 474-479.

- Gorinstein S, Vargas OJ, Jaramillo NO, Salas IA, Ayala AL, et al. (2007) The total polyphenols and the antioxidant potentials of some selected cereals and pseudocereals. Eur Food Res Techn 225(3-4): 321-328.

- Gorinstein S, Lojek A, Ciz M, Pawelzik E, Delgado-Licon E, et al. (2008) Comparison of composition and antioxidant capacity of some cereals and pseudocereals. Int J Food Sci Techn 43(4): 629-637.

- Cai Y, Sun M, Corke H (2003) Antioxidant Activity of Betalains from Plants of the Amaranthaceae. J Agr Food Chem 51 (8): 2288-2294.

- Gamel TH, Linssen JP (2006) Nutritional and medicinal aspects of amaranth. Recent Progress in Medicinal Plants 15(5): 347-361.

- Sala M, Berardi S, Bondioli P (1998) Amaranth seed: the potentials. Riv Ital Sostanze Grasse 75 (11): 503-506.

- Kalac P, Moudry J (2000) Composition and nutritional value of amaranth seeds. Czech J Food Sci 18(5): 201-206.

- Prakash D, Joshi BD, Pal M (1995) Vitamin C in leaves and seed oil composition of the Amaranthus species. Int J Food Sci Nutr 46(1): 47-51.

- Zeashan H, Amresh G, Singh S, Rao Ch V (2008) Hepatoprotective activity of Amaranthus spinosus in experimental animals. Food Chem Toxic 46 (11): 3417-3421.

- Verma RK, Sisodia R, Bhatia AL (2002) Radioprotective Role of Amaranthus gangeticus Linn.: A Biochemical Study on Mouse Brain. J Med Food 5(4): 189-195.

- Kamal R (2007) Radio-protective role of Amaranthus paniculatus L. on the sensitivity of mouse spermatogonia after exposure to gamma radiation. Himalayan J Envir Zool 21(2): 315-318.

Mini Review

Mini Review