Abstract

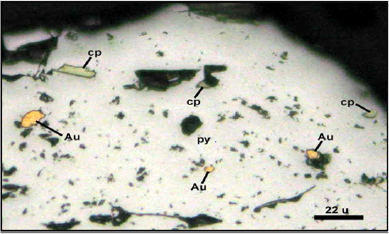

The sample that is the subject of research study is a partially oxidized mineral with a calculated head grade of 16.20g/MT; provided by artisanal miners from the province of Canta, department of Lima. The characterization of the sample was carried out in the polarized optical microscope, at the Professional School of Geological Engineering of the UNMSM, where the presence of gold, chalcopyrite, covelite, chalcosite, sphalerite, pyrite, arsenopyrite, magnetite, goethite, rutile and bargains In addition, we find interlaced particles of gold with chalcopyrite and pyrite, the rest of the gold must be within the mineralogical species of the sulphured minerals. This makes the recovery of gold low, due to the amalgamation process, which uses artisanal mining. The best selected preconcentration test, with the Knelson gravimetric concentrator is with a grain size of 67.13%-200 mesh, obtaining 300.20g/MT of concentrate, 33.66% recovery and 51.59 radius of concentration. The best cyanidation test of the tailings of the preconcentration of the Knelson gravimetric concentrator, with the sample not removed, with 24 hours of leaching, granulometry of 52.25% - 200 mesh and 300RPM of agitation, 75.96% gold recovery is obtained with a consumption of sodium cyanide of 1.16Kg / TM.

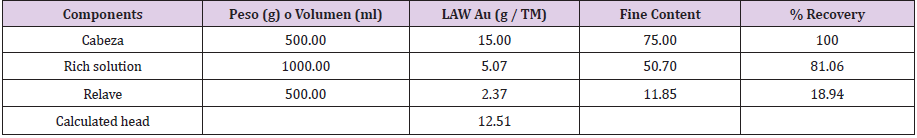

By rewinding the tailings of the preconcentration to a particle size of 87.25% - 200 mesh, 48 hours of leaching and 500 RPM of agitation, a gold recovery of 81.06% is reached with a sodium cyanide consumption of 2.52 Kg/TM. The total recovery of gold from both the preconcentration and cyanidation of the tailed gravimetric preconcentration tailings is 87.44%. The appropriate metallurgical process according to the results of the present research at the laboratory level, for the processing of minerals from artisanal miners in the province of Canta, is a preconcentration with the Knelson gravimetric concentrator, removing the tailings from preconcentration and Perform the cyanidation process, to obtain a total recovery of 87.44% gold, with a consumption of sodium cyanide of 2.52 Kg/TM, without the use of mercury thereby reducing environmental pollution.

Keywords: Preconcentration; Cyanuration; Mercury; Recovery; Knelson

Introduction

1] in his research Mining and Environmental Pollution in Piura. Universidad Nacional de Piura Postgraduate School. Master’s Program in Environmental Engineering. The objective of the investigation was to determine the existence of environmental pollution from mining in Piura. Results: Evidence of contamination in air, soil and water was found with products such as cyanide and mercury. Informal artisanal gold mining causes environmental pollution problems due to the use of mercury, due to the use of obsolete and traditional technologies. As well as accidents due to unsafe working conditions, exploitation of children of minors and mothers of families, etc. The present investigation is justified because artisanal mining has problems of environmental pollution due to improper use of mercury, informality and low gold recovery. According to the bulletin of the Institute of Health and Labor, through COSUDE- GAMA Project published in December 2004; He mentions that mercury is a highly toxic metal for minors, since it produces irreversible damage to the central nervous system (brain), and can lead to death in the most severe cases. In artisanal mining, Quimbaleteo or amalgamation is used, where mercury is added manually to the quimbalete’s pit, then it is squeezed out, to obtain the amalgam ball.

The exposure to contact with mercury is more evident, since it is fully manual, here we must observe that not only through the skin does the mercury enter the body but also through the nails, through the nail bed, which is the part below The nail. Also in the bulletin they indicate the mechanism of how mercury is introduced through the skin. Mercury is a substance that has a property of liposolubility, that is; in small quantities it crosses the skin barriers, so that in prolonged exposure times the mercury that enters, passes into the bloodstream and travels throughout our body damaging our kidneys, liver and especially our brain. In refueling or burning, it is performed outdoors or worse; Inside a room that is one of the most direct and dangerous forms of poisoning. It is necessary to point out that the rudimentary protection of a handkerchief that covers the mouth or nose does not help at all, since the mercury vapors that produce the burning of amalgam can pass through the tissue of the handkerchief. While the reflux occurs, where the vapor-shaped mercury is found in tiny particles and they travel through our bronchi reaching a very deep part where the breathing process takes place, it is here where the mercury again enters the blood and disperses throughout our body. Likewise, harmful is the dust produced by the permanence of the tailings in the pools when the water evaporates.

Due to the high current prices of gold, the surrounding towns and the communities of the mountains, (as is the case in the province of Canta) find job opportunities abandoning agriculture, because mining activity is more profitable. The research study conducted on the tailings of the amalgamation process of artisanal mining yields worrying results, the gravimetric preconcentration tailings have 3.67 ppm of mercury and the cyanidation tailings have 2.70 ppm of mercury. These values are high, if we compare with the maximum permissible limits that is 0.14 ppm. This means permanent contamination of basins and tailings fields [2-5]. The study aims to reduce pollution by avoiding the use of mercury and improving productivity in the recovery of gold.

Experimental Part

Characterization of the Mineral

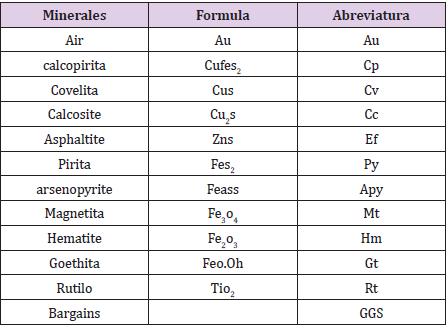

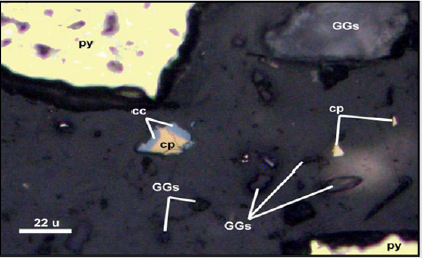

The analysis carried out on the sample has allowed determining its mineralogical constituents, the volumetric distributions, of those minerals that have intervened in the modal analysis, their respective degrees of release and the interpretation of the degrees of release for each of the minerals. In the following table the observed minerals and those that have participated in the modal analysis are inserted (Table 1).

Mineralogical Interpretation

Gold Minerals As gold ore is gold.

Copper Minerals. As copper minerals are chalcopyrite, covelite and chalcosite.

Zinciferous minerals. As zinc ore is sphalerite

Ferriferous minerals. As iron ores are pyrite, arsenopyrite, magnetite, hematite and goethite

Other minerals Within this group are the rutile and bargains.

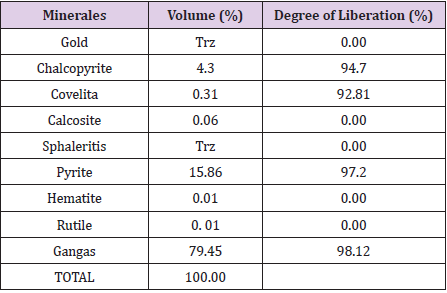

Volumetric Percentage Distribution and Degrees of Release

The volumetric distribution and the weight in percentage terms, in the same way with respect to the degrees of release; which are provided for all the minerals that have intervened in the modal analysis and can be seen in the following table (Table 2).

Pre-concentration tests with the Knelson Gravimetric Concentrator

To perform preconcentration metallurgical tests with the Knelson gravimetric concentrator, it is important that the sample is representative and that the independent variable is granulometry. The best test obtained is indicated [6-10].

Test Conditions

Sample weight: 5000 g

Gravity Force: 60 G’s

Granulometries: 52.25%, 60.66%, 67.13%, 74.64% - 200 mesh

Water Pressure: 3 psi

Cyanuration Testing of Knelson Gravimetric Concentrator Tailings

Test Conditions:

Sample weight: 500g

L / S ratio: 2/1

Granulometries: 52.25%, 60.66%, 67.13%, 74.64% - 200 mesh

Cyanuration Time: 24hrs

pH: 10.5

Agitation: 300 RPM

The best test obtained is indicated.

Metallurgical Testing of Cyanuration of the Tailings of the Gravimetric Concentrated Concentrator, Increasing Time and Agitation

Test Conditions:

Sample weight: 500 g

L / S ratio: 2/1

Granulometry: 87.25% - 200 mesh

Cyanuration Time: 48hrs

pH: 10.5

Agitation: 500 RPM

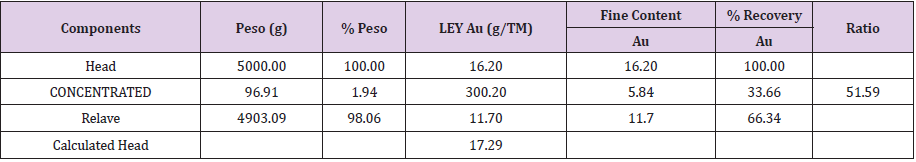

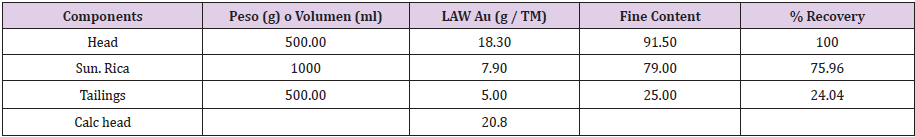

In the first stage, which is the preconcentration with the Knelson gravimetric concentrator, the best metallurgical test selected is indicated in (Table 3), where the quality of the concentrate is 300.20g/MT, recovery of 33.66% and a concentration radius of 51.59, with a grain size of 67.13% -200 mesh. In the second stage which is the cyanidation of the tailings of the preconcentration of the Knelson gravimetric concentrator, the best metallurgical test selected is (Table 4), where the recovery of gold is 75.96%, with a cyanide consumption of 1.16Kg/TM, with a granulometry of 52.25% -200 mesh. By varying the conditions of the cyanidation process of the second stage consisting of: removing the tailings of the preconcentration of the Knelson gravimetric concentrator at a granulometry of 87.25% - 200 mesh, stirring revolution at 500 RPM and cyanidation time at 48 hours. As a result, a recovery of 81.06% is obtained with a cyanide consumption of 2.52Kg / MT, as indicated in (Table 5).

Table 3: Metallurgical Balance of the Knelson Gravimetric Concentrator at 67.13% - 200 mesh.

Source: self-made

Table 4: Mosquito Abundance in Relation to Feeding Time and Points.

Note: NaCN Consumption: 1.16 Kg/TM

Cal consumption: 9.28 Kg/TM

Source: self-made

Table 5: Metallurgical Balance Cyanidation of the Remolido Gravimetric Tail.

NaCN Consumption: 2.52Kg/TM

Cal consumption: 11.05Kg /TM

Source: self-made

Finally, the independent variable selected in the preconcentration is a granulometry of 67.13% - 200 mesh, to obtain a recovery of 33.66% gold and in the cyanidation a granulometry of 87.25% -200 mesh, to obtain a gold recovery of 81.06%. The total recovery of the preconcentration and cyanidation process of the gravimetric tailings was 87.44%, which is the dependent variable obtained. In the appropriate process selected, there is an additional advantage of not using mercury in preconcentration with the Knelson gravimetric concentrator, consequently, there is a reduction in environmental pollution [11-21].

Conclusion

a) The result of the characterization of the sample of the mineral studied indicated the presence of gold, chalcopyrite, covelite, chalcosite, sphalerite, pyrite, arsenopyrite, magnetite, goethite, rutile and bargains.

b) The best test selected in preconcentration, with the Knelson gravimetric concentrator is with a granulometry of 67.13% - 200 mesh, as an independent variable obtaining 300.20g/MT of concentrate, 33.66% recovery which is the dependent variable (Table 3). In this stage the free and coarse gold of the sample is recovered and environmental pollution is reduced, because only water is worked without the use of mercury (Figures 1-3).

Figure 1: Free particles of chalcopyrite (cp), pyrite (py) and GGs bargains); at the center of the sight an intertwined chalcopyrite particle (cp) with the chalcosite (cc). 200X. Source: Gagliuffi, P. (2010).

Figure 2: Interlaced gold particles (Au) with chalcopyrite (cp) and pyrite (py); notice. Gold grain sizes (Au), the largest has a dimension of 17 microns (i.e. 0.017 mm) in length. 400X.

Source: Gagliuffi, P. (2010).

c) By rewinding the tailings of the preconcentration to a granulometry of 87.25% - 200 mesh as an independent variable, with 48 hours of cyanidation and 500 RPM of agitation, a gold recovery of 81.06% dependent variable is reached (Table 5).

d) The total recovery of gold from both preconcentration and cyanidation of the preconcentration tailings is 87.44%, which is the dependent variable. Compared to the work done by artisanal mining that reaches between 40 and 50% gold recovery with the conventional amalgamation process.

e) The appropriate metallurgical process according to the results of the present investigation, for the processing of minerals from artisanal mining in the province of Canta, is a preconcentration with the Knelson gravimetric concentrator, removing the tailings from the preconcentration and carrying out the process of cyanidation, to obtain a total recovery of 87.44% gold, without the use of mercury.

Recommendations

With the results obtained in this research, it is recommended that the metallurgical process studied is an alternative for artisanal gold mining in the province of Canta, because it replaces the conventional amalgamation process, improving the recovery of gold and reducing environmental pollution by the nonuse of mercury.

a) It is recommended that artisanal miners in the province of Canta group and process their ore directly and can be replicated as a model for artisanal mining in general, improving their profitability.

b) It is recommended to carry out tests at the pilot plant level, with the variables obtained from this research work.

References

- Piscoya J (2011) Thesis Mining and Environmental Pollution in Piura. Universidad Nacional de Piura - Post Graduate School. Master's Program in Environmental Engineering.

- Aramburú V (2009) Recovery of Gold and Mercury from the Tailings of the Amalgamation Process with Clean Technology. Final Technical Research Report - National University of San Marcos, Peru.

- Bergamashi G (1987) Gold. Editorial Mondadori. Spain.

- Brewis T (1995) Separation by Gravity Edit. Minig. Canada.

- Dana J (1992) Dana Mineralogy Manual. 19th Riverte editorial. Spain.

- Gómez O (1988) Environmental impact assessment World Editions. Madrid.

- Hernández R (2006) Investigation methodology. Mc Graw-Hill. Mexico.

- Hurtado H (2003) Hidden gold in Peru. UNAS editorial. Lime.

- Knelson BV (1988) Centrifugal Concentration and Separation of Precious Metals. Memories: 2nd International Conference on Gold Mining, Canada.

- Laplante A (1990) Gold Gravity Recovery at the Mill of Les Mines Camchib Inc., Publisher: Chibougamau, Quebec.

- Lázaro, H, Trillo A, Sánchez P (1995) "Study of informal gold mining and the environment in the Puno area," mimeo IDESI - MEM. Lime.

- Long Roberts (2001) Peasant and Business Miners. Editorial Institute of Peruvian Studies. Peru.

- López A (2011) Thesis Centrifugal gravimetric concentration of gold and silver and its implementation in the El Pilón mining mill. Autonomous University of San Luis de Potosí: Mexico.

- Mosquera C, Trillo A, Luján A (1999) "Proposal for an Action Plan for the GAMA Project," Final Report Swiss Agency for Development and Cooperation-SDC. Lime.

- Ounpuu M (1992) Gravity Concentration of Gold from Base Metal Flotation Mills; Memories: 24th Annual Meeting of the Canadian Mineral Processors, Ottawa, Ontario.

- Palomino A, Ramos O (2008) Thesis Evaluation of the recovery of gold and silver from sulphured minerals in a quartz matrix - Minera Koricolqui. Presented at the National University of San Marcos.

- Tyler, Miller (1994) Ecology and Environment. Editorial: 21st Mexico.

- Viñas R Araníbar A (2003) Small mining and artisanal mining in Latin America. CETEM editors.

- Viñas R Araníbar A (2006) Clean technologies in the mining and metallurgical mining industries. CETEM.

- Wotruba H, Vasters J (2002) Study to improve the process of chemobale minimizing high losses of mercury. GAMA project, Peru.

- Zevallos W (1994) Neither Gold nor Silver ... Displaced Violence and Artisanal Mining in the Libertadores-Wari Region. Lima: EPRODICA.

Research Article

Research Article