Impact Factor : 0.548

- NLM ID: 101723284

- OCoLC: 999826537

- LCCN: 2017202541

Suhaib Ahmed* and Vipan Kakkar

Received: October 13, 2017; Published: October 20, 2017

Corresponding author: Suhaib Ahmed, Department of Electronics and Communication Engineering, Shri Mata Vaishno Devi University, Katra, India

DOI: 10.26717/BJSTR.2017.01.000454

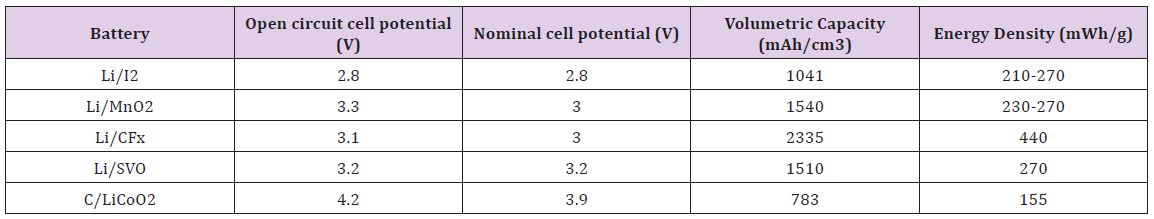

The implantable medical devices require constant power source and for this requirement, batteries have been developed that has enabled the successful deployment of the devices and their treatment of human disease. While the functional requirements for the batteries used to power these devices vary with the type of device and therapy, there are some characteristics that are demanded by all applications. The batteries must have high life span, be safe during installation and use, have predictable performance that can be interrogated to provide state of discharge information and be highly reliable [1]. Additionally, the batteries must have high volumetric energy density to enable the design of small devices that minimize discomfort for the patient. Thus, long term stability during use, predictable performance, high volumetric energy density and outstanding reliability are key characteristics that define successful systems for biomedical implants [1]. Since the introduction of first cardiac implant in 1972, a variety of battery systems have been developed for implantable medical devices that utilize lithium metal anodes with cathode systems including iodine (Li/I2) [2-4], manganese oxide (Li/MnO2) [5,6], carbon monofluoride (Li/CFx) [7,8], silver vanadium oxide (Li/SVO) [9,10] and hybrid cathodes using both carbon monofluoride and silver vanadium oxide (Li-CFx-SVO) [11,12]. The specification of these batteries is presented in Table 1.

Table 1: Comparison of Different Batteries Used in Implantable Medical Devices.

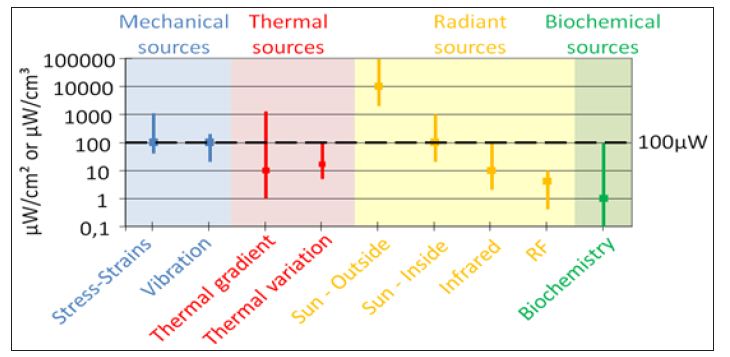

This range of batteries provides the appropriate power levels as demanded by a specific medical device varying from microampere to ampere level currents. Successful development and implementation of these battery types has helped enable implanted biomedical devices and their treatment of human disease. Among these, Li/I2 has proved to be safer and more reliable than others for use in pacemakers and hence used widely in the last 4 decades [13]. However, these batteries suffer from limited life span and hence require replacement by surgery which is inconvenient to the patient. Hence an alternate energy source is required to continuously power these implants. One such approach which can address the abovementioned problem is Energy Harvesting [14,15]. It is the process of scavenging out energy from different sources in the ambient environment. Various harvesters are being proposed to harvest energy for implantable devices. Some of the recently reported harvesters can be studied in [15-21]. The form of energy used by the harvester to scavenge the power, defines the type of energy harvesting. There are four main ambient energy sources available viz., mechanical energy due to vibrations and deformations (electrostatic, piezoelectric and electromagnetic), thermal energy (temperature variations and gradients), radiant energy (sun, IR, RF) and biochemical (bio-fuel cells). A comparison of the power densities of these different energy sources is presented in Figure 1 [15,22].

Figure 1: Comparison of power densities of different ambient energy sources.

Although research is being carried out on designing different structures of energy harvesters to generate as much power as possible, there are still some aspects that need to be investigated before finally implanting the harvester inside the body. One such area is the stability of the harvester. For example in electret-based electrostatic harvesters, the electret stability degraded at high temperature and humidity and at higher surface potentials which can reduce the life-span of the harvester. Another aspect that has to be investigated is the toxicological effect of the harvester, if any. But given the trend of the energy harvested by different structures being proposed, the practical application of the harvesters in implantable microsystems as a reliable power source will certainly be a reality.