ABSTRACT

The food sector addresses perhaps of the main business with regards to degree, speculation, and variety. In a forever evolving society, dietary requirements and inclinations are broadly factor. Alongside offering an extraordinary mechanical help for inventive and valued items, the ongoing food industry ought to likewise cover the essential necessities of a consistently expanding populace. In this unique circumstance, designing, examination, and innovation have been joined to offer supportable arrangements in the food business for a solid and fulfilled populace. While wellbeing and prosperity are key drivers of the food business, market influences take a stab at development all through the total pecking order, including unrefined substance/fixing obtaining, food handling, quality control of completed items, and bundling. Food safeguarding strategies have been experimentally utilized starting from the beginning of mankind. Thus, our ancestors used to handle raw materials such as milk, meat or fish in a way that extended their shelf-lives by using practical methods based on what we now know as drying, curing or fermentation. Hundreds of years after the fact and during the modern transformation toward the start of the nineteenth 100 years, Appert fostered the cycle for business cleansing of canned food items, which thusly opened the way to the advancement of safe food items with delayed timeframes of realistic usability. Active food packaging strategies have experienced a tremendous push forward in the last two decades. During this time, the improvement of fresher materials and the consolidation of bioactive mixtures in the bundling films have addressed an upheaval in the food business and have run in equal (and in some cases prodded by) with the improvement of cutting-edge procedures for the recognition of arising and safe food-borne microbes. When the microbial dangers for each sort of food item are known and the microbial targets definitively distinguished, it is an ideal opportunity to conclude what bioactive compound will be more reasonable for every particular application.

Keywords: Food Preservation; Packaging Techniques; Processing of Foods

Introduction

The packaging is likely the most important method for food preservation due to protects, preserves and provides the needed information about the product, while allows the product commercialization and distribution [1,2]. The qualities of the packaging are determined by the food item that needs to be safeguarded. As of now, a variety of materials have been used as packing materials, including paper, cardboard, metal, glass, and plastic. [3]. But it’s most likely that this conventional preservation technique is the one that generates a lot of urban solid trash (USW). Food and packaging interactions may be harmful to quality and/or safety. When meals are packaged in polymer-based materials, aroma sorption changes in product flavor and the transfer of unfavorable flavors from packaging to foods are significant processes of deterioration. In order to enhance product quality, safety, and shelf life while limiting undesired changes, active, intelligent packaging is developed based on a deliberate interaction of the packaging with the food and/or directly improves food quality and safety.

The following developments in delayed oxidation and controlled respiration rate, microbial growth-inhibiting microorganisms and moisture migration, and the addition of carbon dioxide absorbers/ emitters, odor absorbers, ethylene removers, and aroma emitters are examples of active packaging that has the desired effect on the food. Intelligent packaging includes time-temperature indicators, ripeness indicators, biosensors, and radiofrequency identification, r. The bioactive substance is regulated released when a positive interaction between the packaging, environment, and food takes place. [4,5], as it is in controlled-release packaging (CRP). Active and intelligent materials are included in the category of «smart packaging.» Active packaging systems are those that have additives that are consciously introduced to the packaging, and which improve the stability of food quality and safety. They can also be based on conditions that are created when food comes into direct contact with the packaging, which enhances food stability. Active packaging therefore includes controlled-release packaging. Food safety, shelf-life extension, and food quality all depend heavily on packaging.

According to Li et al., the shelf life of food is «the amount of time that a food remains acceptable in terms of flavor, color, aroma, texture, nutritional content, and safety, under specified environmental circumstances.» [6]. There are some effective methods, such as using active packaging or quickly or instantaneously adding active substances (such antioxidants and antimicrobials) to the food formulation in a small amount. [7- 9]. Many innovations in packaging technology have emerged in recent years, including active packaging and intelligent or smart packaging (AP, such as oxygen scavengers, moisture absorbers, and antimicrobials) [7]. These innovations are responsible for the improvement in food quality, safety, and shelf life. However, as most packages are made up of a combination of materials with various properties, businesses that choose to recycle the materials must also deal with the classification problem. The recovery, choice, cleaning, and reprocessing of materials currently make recycling a challenging and pricey task. [2]. For this reason, renewable raw materials have been deeply explored in recent years at aiming to minimize pollution problems through alternative biodegradable packaging [6].

As a result, packaging made of biodegradable materials has developed as a replacement for conventional materials that cannot be recycled. Such biodegradable materials can shield the product while being relatively simple to produce, recycle, and degrade. [1]. The majority of biodegradable packaging often involves the use of ecologically friendly polymeric materials with the goal of preserving quality and prolonging the shelf life of minimally processed goods, like fruits and vegetables [9,10]. This review objective is to give an overview of the state-of-the-art in edible film and coating use in various foods, with a focus on the key ingredients (such as biopolymers, additives, bioactive ingredients, and probiotic components), manufacturing processes (for edible film or coatings), and their use in particular products. Additionally, this analysis outlines the key requirements biodegradable packaging must fulfil in order to be used in certain applications for the preservation and enhancement of various food products. These applications include edible films and coatings.

Purpose of Food Preservation

The main reasons for food preservation are to overcome inappropriate planning in agriculture, to produce value - added products, and to provide variation in the diet [11]. Various segments of the agriculture business generate the raw ingredients for food. By avoiding incorrect locations, timings, and quantities of raw food components as well as by extending storage life utilizing straightforward preservation techniques, inadequate management or improper planning in agricultural production can be overcome. Value-added food items can offer better-quality foods with greater nutritional, functional, practical, and sensory attributes. Food preservation techniques are impacted by consumer demand for healthier and more convenient food options. Consumers should not find eating to be monotonous; it should be enjoyable. People enjoy eating a wide variety of foods with various flavors and tastes. In order to lessen reliance on a single type of grain, diet variety is crucial, especially in underdeveloped nations (i.e., rice or wheat). Likewise, food protection, stockpiling and appropriation are additionally significant elements in accomplishing food security. In food protection, the significant focuses that should be considered are wanted quality, wanted rack - life, and target shoppers should be in every way considered while saving food.

Methods for Food Preservation

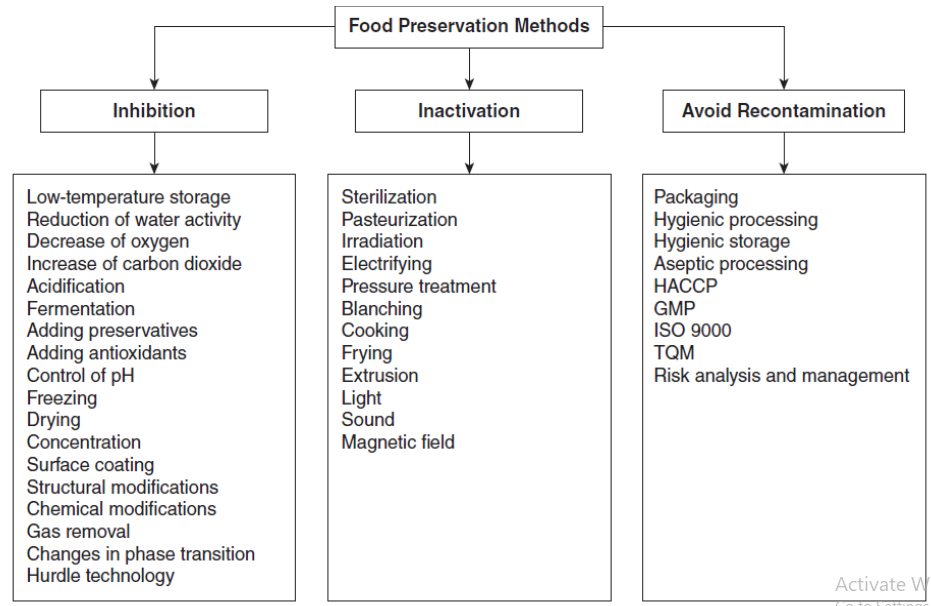

At present various techniques for food conservation are accessible for the food business. In view of the method of activity, the significant food protection procedures can be categorized as

(i) Slowing down or inhibiting chemical deterioration and microbial growth,

(ii) Directly inactivating bacteria, yeasts, molds, or enzymes, and

(iii) Avoiding recontamination before and after processing [12].

(Figure 1) displays a handful of the techniques or procedures from the aforementioned areas. It would frequently be quite challenging to distinguish between inhibition and inactivation clearly. Consider the preservation method of freezing and drying. Although controlling the growth of microbes during storage is the primary goal of freezing and drying, certain bacteria are also destroyed. Ten to sixty percent of the viable microbial population appear to die when things are frozen, and this number rises over time as things are stored. The sections that follow list various techniques for food preservation. [11].

Food Packaging and Its Role in Food Preservation

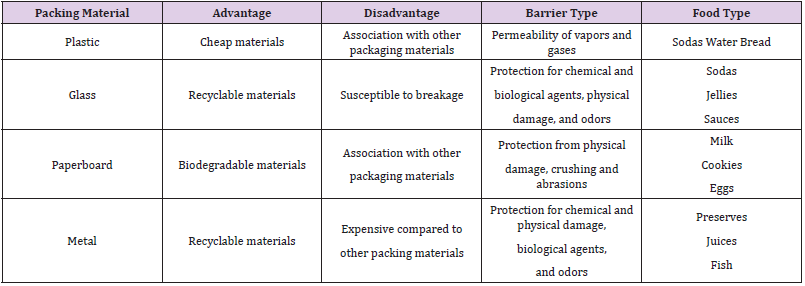

The packaging is now the most crucial stage after foods have undergone minimum or complete processing since it enables transportation from the factories to the point of sale or distribution. As a result, this substance helps to keep the majority of the food’s physicochemical, functional, and organoleptic qualities. [2-9]. In addition to this, the packaging must not interact with the product and protect it from external damage of chemical, physical, and biological type [2]. Physical damage comprises any harm brought on by shock or vibration, whereas biological damage is brought on by diseases, insects, animals, or the ageing process of the food itself [9]. Chemical damage also includes exposure to gases, moisture, and light. The overview of various food packaging materials, including plastic, metal, glass, and paper, is covered in the following section with a focus on food preservation (Table 1).

Edible Films and Coatings as Packing Materials

Characteristics of Edible Films and Coatings

An edible film or covering is any material with a thickness of under 0.3 mm [13], which is shaped from a blend of biopolymers and various added substances scattered in fluid media [14-17]. Some publications interchangeably refer to edible film and coating, but others believe there is a difference because of how they are incorporated into the food product [18]. While the edible film is first manufactured and then adhered to the product, the edible coating is formed immediately on the food [19-23]. Despite this, rigid matrices with comparable properties are generated in both situations [6-24].

Materials of Edible Films and Coatings

Edible films and coatings are frequently assessed for their mechanical properties, such as their elasticity and stiffness, as well as the force required to break them, using terms like elongation at break (E), tensile strength (TS), and elasticity modulus (EM) [25- 31]. Additionally, they exhibit similar mass transfer mechanisms (permeation, adsorption, and diffusion) that are connected to the movement of solutes between food and the atmosphere [32]. However, the kind of material and manufacturing process that enable the development of various architectures of biopolymeric matrices have an impact on both mechanical properties and mass transfer phenomena [33-36]. (Table 2) includes the top biopolymers and additives utilised in the creation of edible films and coatings, along with information about their characteristics and packing capabilities. Due to its traits and gelatinization abilities, starch is regarded as the universal biopolymer for bio-packaging, which has been utilized extensively for decades [37]. Another significant biopolymer that has the capacity to create hydrogels and encapsulation barriers is alginate [38-41]. However, due to its qualities as a gelling agent, chemical (it could form hydrogen bonds and hydrophobic interactions), and biological (its biocompatibility, biodegradability, and bioactivity) properties, chitosan has recently attracted attention for the development of edible films and coatings [42,43].

While other authors have chosen to use additional organic ingredients to create packaging, such as proteins (such as collagen and protein isolates) [44,45], lipids (such as canola oil and cinnamon bark oil) [46,47], as well as other unusual materials (such as smooth-hound protein and papaya puree) [48,49], to create bio-packaging with specific properties. The purpose of additives, such as plasticizers or stabilisers, is to change the mechanical characteristics of edible films and coatings (ideally, to improve E and decrease TS and EM), as well as mass transfer phenomena [6,29]. Additionally, adding anti-oxidant, fungicidal, or microbial additives enables the creation of bioactive bio-packaging [50,51].

Disperse Systems Forming Edible Films and Coatings

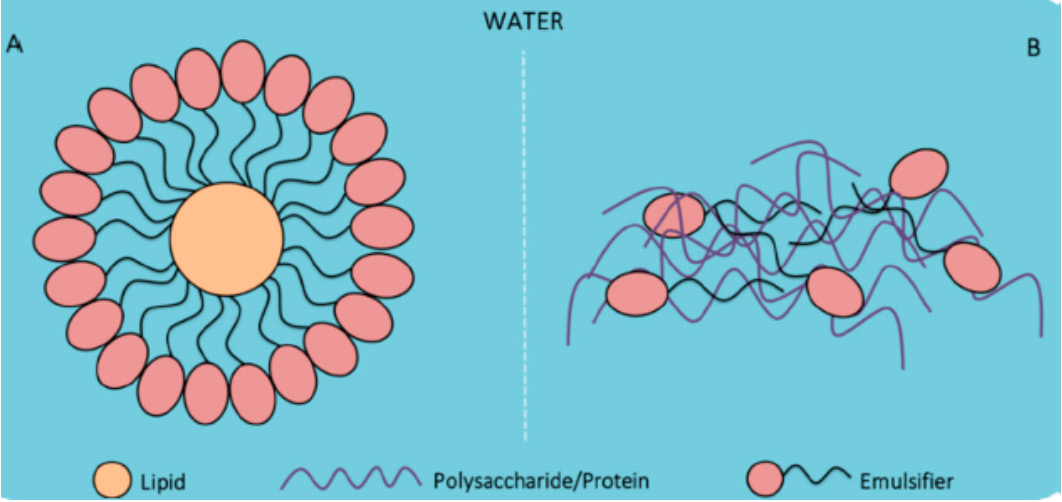

Due to their glucidic (i.e., polysaccharide), proteinic, or lipidic nature, biopolymeric materials used for the formulation of biopackaging are incorporated in various ways, resulting in dispersed emulsion-type (i.e., based on lipids) or colloidal systems (i.e., based on polysaccharides or proteins) systems [52]. The two kinds of systems that can be created for the production of edible films and coatings are shown in (Figure 2). Emulsions are systems made up of substances that are immiscible with one another and are liquid or semi-liquid in nature, such as an oil and an aqueous phase that can be combined with the aid of an emulsifying agent. An affinity for both polar and non-polar sites can be seen in the emulsifying agent’s hydrophilic and hydrophobic zones [26,62]. Because the dispersed phase corresponds to the second component and is in lower concentration in the emulsion, emulsions can be divided into two categories based on the proportions of their phases, such as oil/water (o/w) or water/oil (w/o) [61,63].

Since they are thermodynamically more stable and can dissolve lipophilic antimicrobial components (like plant essential oils) and bioactive components (like fatty acids, carotenoids, antioxidants, phytosterols, or quinones), o/w systems are preferred in the formulation of edible films and coatings (Figure 2A) [26]. Colloid systems are polymeric structures composed of proteins or polysaccharides that have been dissolved in an aqueous phase [61]; they create a dense matrix that can shield active substances (such as antimicrobial and antioxidant agents) [53] and permit their controlled release within the matrix [54]. Colloidal systems are primarily used for the development of edible films and coatings because they can transport and protect a lot of molecules that act as additives (for example, essential oils) [55,56] and probiotics (for example, lactic acid bacteria) [57,58]. This is because polysaccharides and proteins are hydrophilic substances. Because different types of interactions (such as ionic, hydrogen bridges, or electrostatic interactions) can be produced depending on the type of biomaterial (e.g., protein or polysaccharide), colloidal systems do not produce matrices with an ordered grouping in their polymeric components (Figure 2B) and instead tend to produce matrices with a variety of properties [59,60].

Figure 2: Main types of dispersed systems generated based on biopolymers,

A. Emulsion oil/water (o/w) and

B. Colloidal dispersions.

Recent Advances in Edible Films and Coatings

Bio-Based Packaging

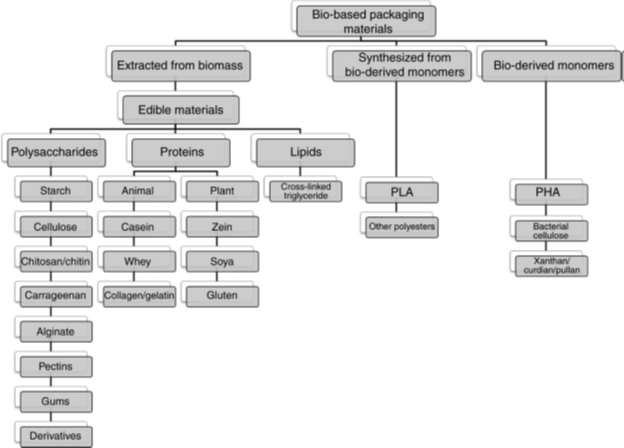

Bio-based packaging is manufactured from biopolymers obtained from fully renewable biological materials, which have to be biodegradable at the end of their life; while biodegradable packaging can be obtained from fossil-based materials or from a combination of renewable and fossil materials, but must be fully degraded and returned to nature. Both terms—bio-based and biodegradable—are sometimes used interchangeably, but not correctly [61-64]. The bio-based packaging, which can be divided into three main categories (i.e., Category 1, 2, or 3) based on their origin and production method, as shown in (Figure 3).

1. Includes polymers directly extracted from natural marine and agricultural souces/resources, such as polysaccharides, proteins or lipids, alone or combined.

2. Encompasses polymers produced by classical chemical synthesis using renewable biobased monomers, such as polylactic acid (PLA, a biopolyester polymerized from lactic acid monomers).

3. Comprises polymers produced by microorganisms or genetically modified bacteria, such as poly(hydroxyalkonoates) (PHAs) and poly(hydroxybutyrate) (PHB), and bacterial cellulose (BC). Some of the most commonly known biobased packaging materials available in the market, in terms of production and renewability, includes PLA, PHAs, starch plastics, cellulose esters, and protein-based plastics. Other biobased plastics, such as bio-enriched polyurethane made from modified vegetable oils, polyethylene monomers derived from the dehydration of bio-ethanol, PP monomers derived from dehydration of bio-butanol and poly(ethylene terephthalate) monomers produced via fermentation, catalytic pyrolysis or gasification of biomass constitute emerging technologies that are expected to have a significant impact in the near future [61,65].

Figure 3: Schematic Representation of Bio-Based Packaging Materials Categorized by Their Source and Method of Production.

Edible Films as Functional Bio-Packages

A bioactive component, as defined by Kris-Etherton et al. [62], is any ingredient present in food in minute quantities that can have an impact on health after intake. Numerous bioactive compounds, such as flavonoids and phytoestrogens, have been the subject of epidemiological investigations [63-68]. These molecules are known for their antioxidant, antimutagenic, anti-inflammatory, anti–cancer, pro–apoptotic, and anti–cholesterol properties. Thus, as mentioned in (Table 2), numerous studies have been explicitly focused on combining a range of these beneficial chemicals into edible films. For example, several authors have evaluated the antioxidant capacity of edible films with phenolic compounds extracted from various sources [69-72]. According to Nogueira et al. [64], the antioxidant activity of blackberry powder is related to its anthocyanin content, and it was maintained when added to arrowroot starch edible films. In addition, the powder’s addition improved the films’ water solubility, water vapour permeability, TS, and E properties while maintaining the colour and flavour of the blackberries.

Based on coconut protein and coconut water, Rodsamram and Sothomvit [71] developed edible films that displayed antioxidant activity provided by coconut phenolic compounds and also acted as a UV radiation barrier due to their brown hue. While Assis et al. [72] produced edible films with increased solute transport and antioxidant activity by extracting and encapsulating _carrot carotenes in a cassava starch matrix. The antioxidant effect in these investigations was produced by bioactive compounds that significantly slow down the oxidation of the substrate as well as by inhibiting reactions involving free radicals [73]. For instance, Abdel Aziz et al. [67] combined castor oil with an alginate matrix to create edible films with an inhibitory effect against Staphylococcus aureus, Bacillus subtilis, Salmonella typhi, and Escherichia coli. Other authors have extracted oils from various sources that have demonstrated antimicrobial activity. Due to an increase in the hydrophilic character of the edible films caused by the hydroxyl groups of edible oil, which easily dissolve the membrane cell and cause the uncontrolled transport of substances into the bacteria, the greatest effect was observed when the concentration of castor oil was increased [74,75].

Citrus peel pectin with oregano essential oil was created into edible films by Alvarez et al. [71] that had an impact on chromobacterium violaceum by preventing cell communication [76]. Similar to this, Alboofetileh et al. [77] employed various essential oils in edible films made of alginate and montmorillonite, including clove, cumin, caraway, marjoram, cinnamon, and coriander essential oils. The films displayed antibacterial efficacy against Escherichia coli, Staphylococcus aureus, and Listeria monocytogenes due to the oils’ presence [78]; The biopolymeric matrix created by alginate and montmorillonite restricted the release of the oils, maintaining a constant inhibitory effect, while marjoram essential oil demonstrated the strongest inhibition due to the regulation of cell growth [79]. Other biologically active substances, such as peptides (such as nisin), enzymes (such as lysozyme), organic acids (such as acetic acid, benzoic acid, sodium benzoate, and sorbic acid), and enzymes (such as nisin), have been incorporated into edible films and coatings for their antimicrobial action [78].

Natural ingredients like citrus plants (like lemon) or essential oils (like cinnamon, clove, and oregano essential oils), as well as their antifungal properties and low toxicity (for the user), have also been proven [80]. For instance, increasing cinnamaldehyde concentration in edible films made from chitosan graphs has demonstrated the antifungal effects against Rhizopus stolonifera and Penicillium italicum [81]. Additionally, according to EM, E, and TS testing, additives (such as cinnamaldehyde) enhanced the mechanical qualities. Cinnamaldehyde and other additives, such as linalool, isoeugenol, and citral, were also assessed by Tarazona et al. [82] in edible films made of an ethylene-vinyl alcohol copolymer. Results against Aspergillus steynii and Aspergillus tubingensis revealed various antifungal activities, but the effect was stronger in the presence of cinnamaldehyde since there was a complete inhibition of fungus [80]. The simultaneous display of several capabilities by bioactive components has the potential to have a synergistic effect. For instance, Ounkaew et al. [83] and Wei et al. [84] examined the antioxidant and antibacterial capability of two distinct edible films with organic acid incorporation.

Based on cassava starch, extracted used coffee grounds, and citric acid, Ounkaew et al. [82] created edible films that demonstrated antioxidant capacity and an inhibitory effect against Escherichia coli and Staphylococcus aureus. This was made possible by the synergistic interaction of the biopolymer and additives, as well as the increasing citric acid content. Ascorbic acid and the lysozyme enzyme were integrated in a zein-based edible film by Wei, et al. [83]. In addition, zein, lysozyme, and ascorbic acid had a synergistic effect on flexibility and mechanical properties. The authors reported that higher enzyme concentrations resulted in better antimicrobial properties against Listeria innocua and Micrococcus lysodeikticus, while the increase of organic acids improved the antioxidant capacity of the edible films [85].

Coatings as Pathogen Inhibitors in Food Models

The majority of the qualities of edible films and coatings are relevant, but one of the most crucial ones is food biological protection because it directly influences the product’s shelf-life. [86]. Because of the action of their enzymes and byproducts created during their metabolism, bacterial or fungal microorganisms (as well as their derivatives) that can induce or accelerate putrefaction in food must be inhibited or eliminated. (e.g., gases) [87]. The lactic acid bacteria are generally recognised as safe (GRAS), and numerous studies have demonstrated their beneficial benefits when administered to the gastrointestinal tract of consumers. (Figure 3) [88]. Since harmful microorganisms are employed in food models, several authors have also concentrated on analysing the inhibitory effect of edible films with Lactic acid bacteria (LAB) and fungus activities. For example, Aloui et al. [89] After covering oranges with two different edible films made of alginate and locust bean gum and inoculating them with Wickerhamomyces anomalus, researchers discovered that the bacteria were more stable in the alginate matrix.

In addition, the alginate edible film was able to inhibit Penicillium digitatum and kept the fruit edible for 13 days. In mandarins coated with edible carob gum edible films, Parafati et al. [90] also inoculated Wickerhamomyces anomalus, Metschnikowia pulcherrima, and Aureobasidium pullulans; the results show a greater inhibitory effect with Metschnikowia pulcherrima against Penicillium digitatum and Penicillium italicum. According to Marn et al. and Fan et al. [91,92], other investigations of microorganisms incubate in coatings for the suppression of harmful fungus. In order to support Candida’s sake and later coat grapes to protect against Botrytis cinerea, several edible films (such as hydroxypropylmethyl cellulose, sodium caseinate, pea protein, and corn starch) were tested in the first study [91]. Although all biopolymers were sufficient to inhibit the pathogen and maintain the survival of Candida’s sake, the authors recommended using sodium caseinate and corn starch because they are the most affordable options. In the second investigation, Fan et al. [92] coated strawberries with edible alginate films containing Cryptococcus laurentii. The authors stated that the bacterium was still alive, and the strawberries’ quality and physical attractiveness were greatly enhanced.

Coatings as Probiotic Carriers in Food Models

Probiotics are a class of bioactive substances that have particular health advantages [93]. Probiotics are defined as «live microorganisms that, when provided in suitable proportions, impart a health benefit on the host» by the Food and Agriculture Organization of the United Nations/World Health Organization (FAO/WHO) in 2002. [94]. Since they are crucial in preserving the microbiota and inhibiting pathogenic microbes in the colon and oral cavity, LAB of the genus Lactobacillus have been extensively researched for their probiotic characteristics. [95]. The authors specifically link the inactivation of pathogens by the effect of organic acids (such as lactic and acetic acids), carbon dioxide, ethanol, peptide compounds, and enzymes, which are produced within LABs metabolism [96]. In addition, there is evidence that links the metabolic activity of LABs with the control of bacterial pathogens and fungal agents [88]. Because it creates an environment where the substrates of LABs and pathogenic microbes compete with one another, other writers link the fall in pH with the inhibitory impact [88,97].

Due to this, rather than focusing on their ability to block exterior pathogens, the most thorough studies in probiotic evaluation have been conducted on the inclusion of microorganisms in edible films and coatings (due to contamination of the environment). An overview of the major organs and systems improved by the ingestion of probiotic bacteria is shown in (Figure 3). Highlighting

(i) The microbiota: the proliferation of pathogenic microorganisms, such as Clostridium difficile and Helicobacter pylori, is regulated.

(ii) The immune system: inflammatory control is maintained.

(iii) The nervous system: brain functions are modulated.

(iv) The placenta: probiotic microorganisms are transmitted to the fetus.

(v) The urogenital tract: urogenital infections are fought; and

(vi) The skin: allergies and atopic dermatitis is helped [88].

Probiotics need to be stabilized or kept alive primarily so that, once consumed, they can endure the conditions of stomach acids and intestinal fluids, allowing for periodic dosing to exert their probiotic effect [72,88]. Thus, under gastrointestinal circumstances (pH 1.8 at 37°C), Gbassi et al. [98] investigated the survivability of Lactobacillus plantarum enclosed in alginate and afterwards injected in an edible film of whey protein; the probiotics remained viable for 180 minutes. The effectiveness and simplicity of the matrix, as well as the price of whey protein and alginate, make this study pertinent. [98]. It’s significant to note that the primary goal of a probiotic embedded in edible films is to investigate and assess their survivability inside the matrix, as well as their interaction with the coated food and probiotic activity. When the edible films are uniquely described in a particular product and stored under various conditions, the vitality of microorganisms varies (e.g., temperature and relative humidity). For instance, Soukoulis et al. [99] assessed the longevity of Lactobacillus rhamnosus in a breadcovering alginate/whey protein matrix.

They were successful in keeping the LAB stable for seven days at 25C. When bread was held at 4°C, the viability period of Lactobacillus reduced significantly (up to 93%), according to the authors’ findings from their earlier study [99], but it increased to 99 days when the matrix was not applied to the bread. [100]. According to Tavera-Quiroz et al. [101], who used Lactobacillus plantarum in a methylcellulose matrix to coat apple baked snacks and maintain their viability up to 90 days in simulated in vitro gastric conditions (two stages: pH 2.5 and 7.5, and 37 C), the viability time of Lactobacillus plantarum can also be compared when stored and treated under different conditions. In order to keep Lactobacillus plantarum viable for 180 minutes, Gbassi et al. [98] employed a whey protein matrix and identical stomach circumstances to Tavera-Quiroz et al. [101]. Particularly, López De Lacey et al. [102] emphasised the need of preserving fresh items, such as fish, given their high perishability and susceptibility to contamination and the proliferation of microbes [12-89]. By adding Lactobacillus acidophilus and Bifidobacterium bifidum to a coating of gelatin, sorbitol, and cysteine, the authors were able to extend the shelf-life of hake fish for up to 15 days at 4°C [102].

Edible Films and Coatings as Food Preservatives

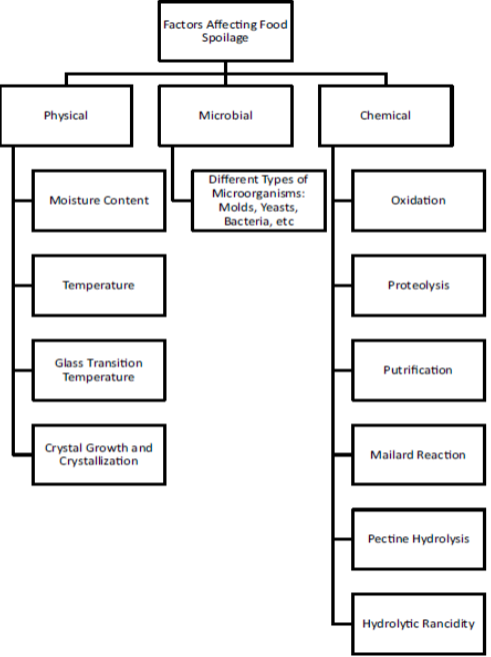

The food industry is now required to provide consumers with food that is tasty, fresh, of high quality, and has positive health effects [8]. As a result of the natural deterioration brought on by chemical, biological, and physical changes, no food can be kept in ideal circumstances or preserve its attributes permanently, making it difficult to meet customer needs [103]. (Figures 4) show, respectively, the various biochemical and physical flaws that have arisen in foods. Unpleasant aromas, rancidity, darkening, softening of the texture, and loss of minerals and vitamins are among the most frequently seen spoiling changes. Oxygen availability, temperature, relative humidity, water content, and pH all affect how quickly food spoils [104]. For this reason, maintaining the qualities of the meal is of utmost importance in addition to the properties of the edible films and coatings themselves, including:

(i) Preservation of nutritional content.

(ii) Preservation of microbiological parameters in accordance with established laws; and

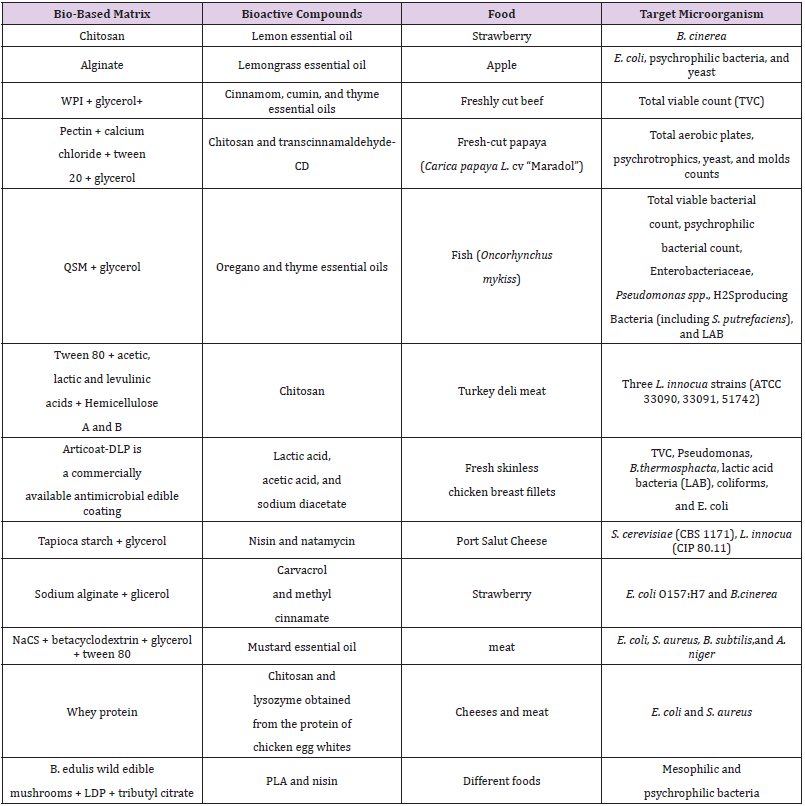

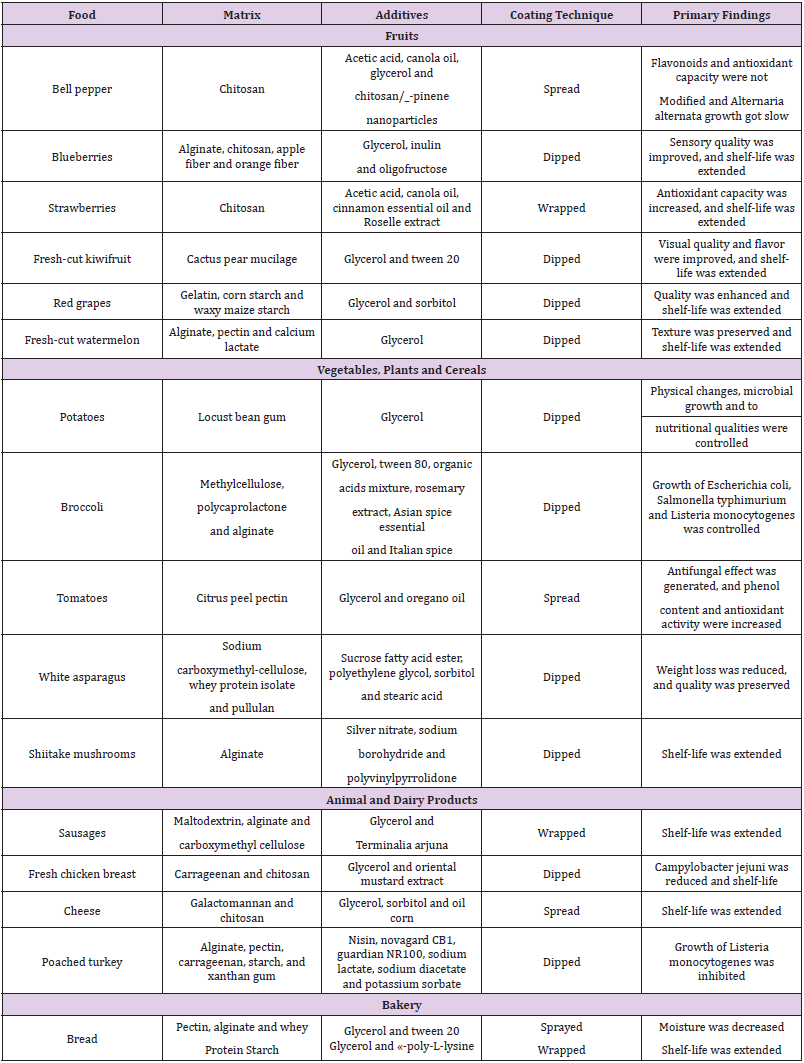

(iii) Preservation of physical and sensory characteristics (e.g., smell, taste, and texture); which together extend the shelf-life of the product. (Table 3) lists various research projects aimed at extending the shelf-life of numerous fruits, vegetables, meat, and dairy products. In these projects, edible films and coatings had a positive impact on physical, chemical, and biochemical parameters, reducing food spoilage and lengthening the shelf-life of the food product. According to the pertinent research findings, depending on the kinds of bioactive solutes incorporated in the edible films and coatings, the maturity in fruits and vegetables as well as the growth of mould and microorganisms can be delayed, preserving particular qualities such as texture, freshness, vitamin C content, and nutritional quality, as well as conferring new biological activities (for example, antioxidant activity). Edible films and coatings allowed for the preservation of the bioactive components of the product itself as well as its sensory qualities in the case of dairy and animal products. They also enhanced the antimicrobial, antifungal, and antioxidant activities as well as the shelf life of these products.

Conclusion

The most recent research on the use of edible films and coatings in a variety of meals has been collated and examined in this chapter. Emphasizing the bio-polymeric materials that have been used to construct novel barriers to directly protect the product, several types of materials have been used in manufacturing packing for the preservation and improvement of food goods. To enhance the physical traits and mechanical qualities of the final packing, particular additives must also be included. In order to increase the functioning and nutrition of perishable and natural foods, bioactive substances, and microorganisms (like probiotics) are now frequently added to sustainable packaging. The primary application methods that set edible films apart from edible coatings were also demonstrated. These methods affect pathogen inhibition, product quality, shelf life, maturation, and maturation effect in addition to the formation materials. To sum up, bio-packaging has proven to be effective at protecting foods that have undergone minimum processing, and its use could result in financial savings by preventing food from spoiling naturally and extending the shelf life of the product. Specific features, such as sensory, physicochemical, and nutritional aspects, in coated products can be improved depending on the biomaterials employed and the kinds of biologically active chemicals. However, there are still a lot of biopolymers (like zein) and additives that haven’t been thoroughly investigated but have good qualities to produce edible films and coatings, which could offer promising insights into the protection and preservation of food products.

References

- Davis G, Song JH (2006) Biodegradable packaging based on raw materials from crops and their impact on waste management. Ind Crops Prod 23(2): 147-161.

- Raheem D (2013) Application of plastics and paper as food packaging materials—An overview. Emir J Food Agric 25(3): 177-188.

- Kishimoto A (1990) New food packaging materials: An introduction. Food Packaging In: Kadoya T (Edt.)., Academic Press Inc.: San Diego, CA, USA, p. 47-51.

- Hotchkiss JH (1997) Food-packaging interactions influencing quality and safety. Food Addit Contam 14(6-7): 601-607.

- Begley TH (1997) Methods and approaches used by FDA to evaluate the safety of food packaging materials. Food Addit Contam 14(6-7): 545-553.

- Li B Kennedy, JF Peng, JL Yie, X Xie, BJ (2006) Preparation and performance evaluation of glucomannan–chitosan–nisin ternary antimicrobial blend film. Carbohydr Polym 65(4): 488-494.

- Vasile C (2018) Polymeric Nanocomposites and Nanocoatings for Food Packaging: A Review. Materials 11(10): 1834.

- Vasile C, Râpa M, Stefan M, Stan M, Macavei S, et al. (2017) New PLA/ZnO:Cu/Ag bionanocomposites for food packaging. Express Polym Lett 11(7): 531-544.

- Butnaru E, Stoleru E, Brebu MA, Darie-Nita, RN Bargan A, et al. (2019) Chitosan-Based Bionanocomposite Films Prepared by Emulsion Technique for Food Preservation. Materials 12(3): 373.

- Han JW, Ruiz Garcia L, Qian JP, Yang XT (2018) Food Packaging: A Comprehensive Review and Future Trends. Compr Rev Food Sci Food Saf 17: 860-877.

- Tavassoli Kafrani E, Shekarchizadeh H, Masoudpour Behabadi M (2016) Development of edible films and coatings from alginates and carrageenans. Carbohydr Polym 137: 360-374.

- Acevedo Fani A, Soliva Fortuny R, Martín Belloso O (2017) Nanoemulsions as edible coatings. Curr Opin Food Sci 15: 43-49.

- Rahman MS (2007) Food preservation: Overview. In: Handbook of Food Preservation In: MS Rahman (Edt.)., CRC Press, Boca Raton FL, p. 3-18.

- Gould GW (1995) Overview. New Methods of Food Preservation In: GW Gould (Edt.)., Blackie Academic and Professional, Glasgow.

- Embuscado ME, Huber KC (2009) Edible Films and Coatings for Food Applications; Springer Science+Business Media: New York, NY, USA.

- Montalvo C, López Malo A, Palou E (2012) Películas comestibles de proteína: Características, propiedades y aplicaciones. Temas Sel Ing Aliment 6:32-46.

- Castro Muñoz R, González Valdez J (2019) New trends in biopolymer-based membranes for pervaporation. Molecules 24: 3584.

- MoralesJiménez M, Gouveia L, Yañez Fernandez J, Castro Muñoz J, Barragan Huerta BE (2020) Microalgae-based biopolymer as a potential bioactive film. Coatings 10(2): 120.

- Guimarães A, Abrunhosa L, Pastrana LM, Cerqueira MA (2018) Edible films and coatings as carriers of living microorganisms: A new strategy towards biopreservation and healthier foods. Compr Rev Food Sci Food Saf 17(3): 594-614.

- Yai H (2008) Edible films and coatings: Characteristics and properties. Int Food Res J 15(3): 237-248.

- Guerrero Legarreta I, Rosmini MR, Armenta RE (2009) Tecnología de Productos de Origen Acuático; LIMUSA: Mexico City, Mexico.

- Falguera V, Quintero JP, Jiménez A, Muñoz JA, Ibarz A (2011) Edible films and coatings: Structures, active functions and trends in their use. Trends Food Sci Technol 22(6): 292-303.

- Salvia Trujillo L, Soliva Fortuny R, Rojas Graü MA, Mc Clements DJ, Martín Belloso O, et al. (2017) Edible nanoemulsions as carriers of active ingredients: A review. Annu Rev Food Sci Technol 8: 439-466.

- Sánchez Aldana D, Contreras Esquivel JC, Nevárez Moorillón GV, Aguilar CN (2015) Caracterización de películas comestibles a base de extractos pécticos y aceite esencial de limón mexicano. CYTA J Food 13(1): 17-25.

- Kra´sniewska K Galus S, Gniewosz M (2020) Biopolymers-based materials containing silver nanoparticles as active packaging for food applications—A review. Int J Mol Sci 21(3): 698.

- Zhang Y, Han J, Liu Z (2008) Starch-based edible films. In Environmentally Compatible Food Packaging;Woodhead Publishing: Sawston, UK, pp. 108-136.

- Castro Muñoz R, Buera González J, de la Iglesia Ó, Galiano F, Fíla V, et al. (2019) Towards the dehydration of ethanol using pervaporation cross-linked poly(vinyl alcohol) graphene oxide membranes. J Membr Sci 582: 423-434.

- Castro Muñoz R, Galiano F, Fíla V, Drioli E, Figoli A (2018) Matrimid®5218 dense membrane for the separation of azeotropic MeOH-MTBE mixtures by pervaporation. Sep Purif Technol 199: 27-36.

- Kim YT, Min B, Kim KW (2014) General characteristics of packaging materials for food system. In Innovations in Food Packaging; Han JH, (Ed.)., Elsevier Ltd.: San Diego, CA, USA, p. 13-35.

- Salama HE, Abdel Aziz MS, Sabaa MW (2018) Novel biodegradable and antibacterial edible films based on alginate and chitosan biguanidine hydrochloride. Int J Biol Macromol 116: 443-450.

- Khazaei N, Esmaiili M, Djomeh ZE, Ghasemlou M, Jouki M (2014) Characterization of new biodegradable edible film made from basil seed (Ocimum basilicum L.) gum. Carbohydr Polym 102: 199-206.

- Martins JT, Cerqueira MA, Bourbon AI, Pinheiro AC, Souza BWS, et al. (2012) Synergistic effects between K_carrageenan and locust bean gum on physicochemical properties of edible films made thereof. Food Hydrocoll 29(2): 280-289.

- Pérez Guzmán CJ, Castro Muñoz R (2020) A review of zein as a potential biopolymer for tissue engineering and nanotechnological applications. Processes 8(11): 1376.

- Veiga Santos P, Oliveira LM, Cereda MP, Alves AJ, Scamparini ARP (2005) Mechanical properties, hydrophilicity and water activity of starch-gum films: Effect of additives and deacetylated xanthan gum. Food Hydrocoll 19(2): 341-349.

- Xiao Q, Lim LT, Tong Q (2012) Properties of pullulan-based blend films as affected by alginate content and relative humidity. Carbohydr Polym 87(1): 227-234.

- Lee KY, Mooney DJ (2012) Alginate: Properties and biomedical applications. Prog Polym Sci 37(1): 106-126.

- Liu J, Liu S, Chen Y, Zhang L, Kan J, et al. (2017) Physical, mechanical and antioxidant properties of chitosan films grafted with different hydroxybenzoic acids. Food Hydrocoll 71: 176-186.

- Bautista Baños S, Romanazzi G, Jiménez Aparicio A (2016) Chitosan in the Preservation of Agritultural Commodities; Elsevier Inc: Oxford, UK.

- Castro Muñoz R, Gonzalez Valdez J, Ahmad Z (2020) High-performance pervaporation chitosan-based membranes: New insights and perspectives. Rev Chem Eng, p. 1-16.

- Ahmad M, Nirmal NP, Danish M, Chuprom J, Jafarzedeh S (2016) Characterisation of composite films fabricated from collagen/chitosan and collagen/soy protein isolate for food packaging applications. RSC Adv 6(85): 82191-82204.

- Slimane EB, Sadok S (2018) Collagen from cartilaginous fish by-products for a potential application in bioactive film composite. Mar Drugs 16(6): 211.

- Moncayo-Martínez DC, Buitrago-Hurtado G, Néstor Y, Algecira-Enciso A (2016) Películas comestibles a base de un biopolímero tipo dextrana Edible films based of dextran biopolymer. Agron Colomb 34(1): 107–109.

- Beak S, Kim H, Song K Bin (2018) Sea squirt shell protein and polylactic acid laminated films containing cinnamon bark essential oil. J. Food Sci 83(7): 1896–1903.

- Abdelhedi O, Nasri R, Jridi M, Kchaou H, Nasreddine B, et al. (2017) Composite bioactive films based on smooth-hound viscera proteins and gelatin: Physicochemical characterization and antioxidant properties. Food Hydrocoll 74: 176-186.

- Rangel-Marrón M, Mani-López E, Palou E, López-Malo A (2019) Effects of alginate-glycerol-citric acid concentrations on selected physical, mechanical, and barrier properties of papaya puree-based edible films and coatings, as evaluated by response surface methodology. Lwt 101: 83-91.

- Ghani S, Barzegar H, Noshad M, Hojjati M (2018) The preparation, characterization and in vitro application evaluation of soluble soybean polysaccharide films incorporated with cinnamon essential oil nanoemulsions. Int J Biol Macromol 112: 197-202.

- Zambrano-Zaragoza ML, González-Reza R, Mendoza-Muñoz N, Miranda-Linares V Bernal-Couoh TF, et al. (2018) Nanosystems in edible coatings: A novel strategy for food preservation. Int J Mol Sci 19(3): 705.

- Silva HD, Cerqueira MÂ, Vicente AA (2012) Nanoemulsions for food applications: Development and characterization. Food Bioprocess Technol 5: 854-867.

- Acosta E (2009) Bioavailability of nanoparticles in nutrient and nutraceutical delivery. Curr Opin Colloid Interface Sci 14(1): 3-15.

- Marcuzzo E, Sensidoni A, Debeaufort F, Voilley A (2010) Encapsulation of aroma compounds in biopolymeric emulsion based edible films to control flavour release. Carbohydr. Polym 8(3): 984-988.

- Aytac Z, Ipek S, Durgun E, Tekinay T, Uyar T (2017) Antibacterial electrospun zein nanofibrous web encapsulating thymol/cyclodextrin-inclusion complex for food packaging. Food Chem 233: 117-124.

- Ortiz CM, Salgado PR, Dufresne A, Mauri AN (2018) Microfibrillated cellulose addition improved the physicochemical and bioactive properties of biodegradable films based on soy protein and clove essential oil. Food Hydrocoll 79: 416-427.

- Abdel Aziz MS, Salama HE, Sabaa MW (2018) Biobased alginate/castor oil edible films for active food packaging. Lwt 96: 455-460.

- Romano N, Tavera-Quiroz MJ, Bertola N, Mobili P, Pinotti A, et al. (2014) Edible methylcellulose-based films containing fructo-oligosaccharides as vehicles for lactic acid bacteria. Food Res Int 64: 560-566.

- Odila Pereira J, Soares J, Sousa S Madureira AR, Gomes A, Pintado M (2016) Edible films as carrier for lactic acid bacteria. LWT Food Sci. Technol 73: 543-550.

- Nayak N, Singh H (2019) Milk protein—Polysaccharide interactions in food systems. Encyclopedia of Food Chemistry In: Varelis P, Melton L, Shahidi F, (Eds.)., Elsevier Inc.: Oxford, UK, pp. 431–438.

- Zhang M, Sun C, Li Q (2018) Interaction between the polysaccharides and proteins in semisolid food systems. Encyclopedia of Food Chemistry In: Varelis P, Melton L, Shahidi F (Eds.)., Elsevier Inc.: Oxford, UK, pp. 439-445.

- Altamirano-Fortoul R, Moreno-Terrazas R, Quezada-Gallo A, Rosell CM (2012) Viability of some probiotic coatings in bread and its effect on the crust mechanical properties. Food Hydrocoll 29(1): 166-174.

- Kris-Etherton PM, Hecker KD, Bonanome A, Coval SM, Binkoski AE, et al. (2022) Bioactive compounds in foods: Their role in the prevention of cardiovascular disease and cancer. Am J Med 113(9): 71-88.

- Peterson J, Dwyer J, Stern F, England N, Mayer J (1998) Flavonoids: Dietary occurrence and Biochemical Activity. Nutr Res 18(12): 1995-2018.

- Bravo L (1998) Polyphenols: Chemistry, dietary sources, metabolism, and nutritional significance. Nutr Rev 56(11): 317-333.

- Castro-Muñoz R, Boczkaj G, Gontarek E, Cassano A, Fíla V (2020) Membrane technologies assisting plant-based and agro-food by-products processing: A comprehensive review. Trends Food Sci. Technol 95: 219-232.

- Díaz-Montes E, Gutiérrez-Macías P, Orozco-Álvarez C, Castro-Muñoz R (2020) Fractionation of Stevia rebaudiana aqueous extracts via two-step ultrafiltration process: Towards rebaudioside an extraction. Food Bioprod. Process 123: 111-122.

- Valencia-Arredondo JA, Hernández-Bolio GI, Cerón-Montes GI, Castro-Muñoz R, Yáñez-Fernández J (2020) Enhanced process integration for the extraction, concentration and purification of di-acylated cyanidin from red cabbage. Sep Purif Technol 238: 116492.

- Castro-Muñoz R, Yañez-Fernandez J, Fila V (2016) Phenolic compounds recovered from agro-food by-products using membrane technologies: An overview. Food Chem 213: 753-762.

- Pérez-Vergara LD, Cifuentes MT, Franco AP, Pérez-Cervera CE, Andrade-Pizarro RD (2020) Development and characterization of edible films based on native cassava starch, beeswax, and propolis. NFS J 21: 39-49.

- Díaz-Galindo EP, Nesic A, Cabrera-Barjas G, Mardones C, Von Baer D, et al. (2020) Physical-chemical evaluation of active food packaging material based on thermoplastic starch loaded with grape cane extract. Molecules 25(6): 1306.

- Khodaei D, Hamidi-Esfahani Z, Lacroix M (2020) Gelatin and low methoxyl pectin films containing probiotics: Film characterization and cell viability. Food Biosci 36: 100660.

- Koc B, Akyuz L, Cakmak YS, Sargin I, Salaberria AM, et al. (2020) Production and characterization of chitosan-fungal extract films. Food Biosci 35: 100545.

- Medeiros Silva VD, Coutinho Macedo MC, Rodrigues CG, Neris dos Santos A, de Freitas e Loyola AC, et al. (2020) Biodegradable edible films of ripe banana peel and starch enriched with extract of Eriobotrya japonica leaves. Food Biosci 38: 100750.

- Nogueira GF, Fakhouri FM, de Oliveira RA (2019) Effect of incorporation of blackberry particles on the physicochemical properties of edible films of arrowroot starch. Dry Technol 37(4): 448-457.

- Rodsamran P, Sothornvit R (2018) Bioactive coconut protein concentrate films incorporated with antioxidant extract of mature coconut water. Food Hydrocoll 79: 243-252.

- Rodsamran P, Sothornvit R (2018) Microencapsulation of Thai rice grass (O. sativa cv. Khao Dawk Mali 105) extract incorporated to form bioactive carboxymethyl cellulose edible film. Food Chem 242: 239-246.

- Aparicio-Fernández X, Vega-Ahuatzin A, Ochoa-Velasco CE, Cid-Pérez S, Hernández-Carranza P, et al. (2018) Physical and antioxidant characterization of edible films added with red prickly pear (Opuntia ficus-indica L.) cv. San Martín peel and/or its aqueous extracts. Food Bioprocess Technol 11: 368-379.

- Alvarez MV, Ortega-Ramirez LA, Gutierrez-Pacheco MM, Bernal-Mercado AT, Rodriguez-Garcia I, et al. (2014) Oregano essential oil-pectin edible films as anti-quorum sensing and food antimicrobial agents. Front Microbiol 5: 699.

- Gómez-Estaca J, López de Lacey A, López-Caballero ME, Gómez-Guillén MC, Montero P (2010) Biodegradable gelatin-chitosan films incorporated with essential oils as antimicrobial agents for fish preservation. Food Microbiol 27(7): 889-896.

- Tarazona A, Gómez JV, Gavara R, Mateo-Castro R, Gimeno-Adelantado JV, et al. (2018) Risk management of ochratoxigenic fungi and ochratoxin A in maize grains by bioactive EVOH films containing individual components of some essential oils. Int J Food Microbiol 269: 107-119.

- Demitri C, Tarantino AS, Moscatello A, De Benedictis VM, Madaghiele M, et al. (2015) Graphene reinforced Chitosan-Cinnamaldehyde derivatives films: Antifungal activity and mechanical properties. In Proceedings of the 1st Workshop on Nanotechnology in Instrumentation and Measurement (NANOFIM), Lecce, Italy IEEE: Piscataway, NJ, USA, p. 25-29.

- Apak R, Güçlü K, Demirata B, Özyürek M, Çelik SE, et al. (2007) Comparative evaluation of various total antioxidant capacity assays applied to phenolic compounds with the CUPRAC assay. Molecules 12(7): 1496-1547.

- Burt S (2004) Essential oils: Their antibacterial properties and potential applications in foods—A review. Int J Food Microbiol 94(3): 223-253.

- Uscátegui YL, Arévalo FR, Díaz LE, Cobo MI, Valero MF, et al. (2016) Microbial degradation, cytotoxicity and antibacterial activity of polyurethanes based on modified castor oil and polycaprolactone 27(18): 1860-1879.

- Choo JH, Rukayadi Y, Hwang JK (2006) Inhibition of bacterial quorum sensing by vanilla extract 42(6): 637-641.

- Alboofetileh M, Rezaei M, Hosseini H, Abdollahi M (2013) Effect of montmorillonite clay and biopolymer concentration on the physical and mechanical properties of alginate nanocomposite films. J Food 117(1): 26-33.

- Van Long NN, Joly C, Dantigny P (2016) Active packaging with antifungal activities 220: 73-90.

- Blackburn CW (2006) Food Spoilage Microorganisms; Woodhead Publishing Limited.

- Rawat S (2015) Food Spoilage: Microorganisms and their prevention 5(4): 47-56.

- Holzapfel W (2015) Advances in Fermented Foods and Beverages. Improving Quality, Technologies and Health Benefits.

- Aloui H, Licciardello F, Khwaldia K, Hamdi M, Restuccia C, et al. (2015) Physical properties and antifungal activity of bioactive films containing Wickerhamomyces anomalus killer yeast and their application for preservation of oranges and control of postharvest green mold caused by Penicillium digitatum 200: 22-30.

- Parafati L, Vitale A, Restuccia C, Cirvilleri G (2016) The effect of locust bean gum (LBG)-Based edible coatings carrying biocontrol yeasts against Penicillium digitatum and Penicillium italicum causal agents of postharvest decay of mandarin fruit 58: 87-94.

- Marín A, Cháfer M, Atarés L, Chiralt A, Torres R , et al. (2016) Effect of different coating-forming agents on the efficacy of the biocontrol agent Candida sake CPA-1 for control of Botrytis cinerea on grapes 96: 108-119.

- Fan Y, Xu Y, Wang D, Zhang L, Sun J, Zhang B, et al. (2009) Effect of alginate coating combined with yeast antagonist on strawberry (Fragaria _ ananassa) preservation quality 53(1): 84-90.

- Pavli F, Tassou C, NychasG J E, Chorianopoulos N (2018) Probiotic incorporation in edible films and coatings: Bioactive solution for functional foods 19(1): 150.

- (2019) FAO/WHO. Guidelines for the Evaluation of Probiotics in Food.

- Borriello SP, Hammes WP, Holzapfel W, Marteau P, Schrezenmeir J, et al. (2003) Safety of probiotics that contain lactobacilli or bifidobacteria 3(6): 775-780.

- Hammes WP, Vogel RF (1995) The genus Lactobacillus. In The Genera of Lactic Acid Bacteria 2: 19-54.

- Gurtler JB, Mai TL (2014) Traditional preservatives-Organic acids. In Encyclopedia of Food Microbiology.

- Gbassi GK, Vandamme T, Ennahar S, Marchioni E (2009) Microencapsulation of Lactobacillus plantarum spp in an alginate matrix coated with whey proteins 129(1): 103-105.

- Soukoulis C , Yonekura L, Gan HH, Behboudi Jobbehdar S, Parmenter C, et al. (2014) Probiotic edible films as a new strategy for developing functional bakery products: The case of pan bread. Food Hydrocoll 39(100): 231-242.

- Soukoulis C, Behboudi Jobbehdar S, Macnaughtan WC, Fisk ID (2017) Stability of Lactobacillus rhamnosus GG incorporated in edible films: Impact of anionic biopolymers and whey protein concentrate 70: 345-355.

- Tavera Quiroz M J, Romano N, Mobili P, Pinotti A, Gómez Zavaglia A, et al. (2015) Green apple baked snacks functionalized with edible coatings of methylcellulose containing Lactobacillus plantarum 16: 164-173.

- López De Lacey AM, López Caballero ME, Gómez Estaca J, Gómez Guillén MC, Montero P, et al. (2012) Functionality of Lactobacillus acidophilus and Bifidobacterium bifidum incorporated to edible coatings and films 16: 277-282.

- Kong F, Singh RP (2016) Chemical deterioration and physical instability of foods and beverages. In Woodhead Publishing Series in Food Science, Technology and Nutrition; Subramaniam, p. 43-76.

- Roudaut G, Debeaufort F (2010) Moisture loss, gain and migration in foods and its impact on food quality. In Chemical Deterioration and Physical Instability of Food and Beverages, pp. 143-185.

- Remize F (2017) Spore-forming bacteria. In The Microbiological Quality of Food: Foodborne Spoilers, pp. 99-120.

Review Article

Review Article