Introduction

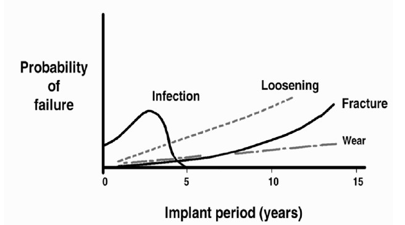

Biotribology is a compound word of biology and tribology this term introduced in 1966 and came from Greek word and science and technology to be combined with friction, wear, and lubrication [1]. In fact, it is an interaction of surfaces. Tribology includes the nature of surfaces from both a chemical and physical point of view, including topography and interaction of surfaces under load [2]. From microscopy view, tribology includes lubrication process with friction and wear. For example, there are four reasons to removes the implants (1) fracture, (2) infection, (3) wear and (4) loosening. (Figure 1) Between them, the removal due to the infection generally occurs in relatively early stages after implantation, while the other three incidents increase by ther years [3,4]. Human joints are one example of natural joints and show low wear and exceedingly low friction through lubrication. Disease and accidents can be function of the joints and it’s necessary for joint replacement [5]. On the other hand, Medical implants, such as prostheses should demonstrate very good tribological properties, as well as biological mertness. Also, their longevity depends significantly on the wear of the rubbing elements. The developments of total replacement like hip, knee, ankle , shoulder and hand joints would not have been possible without extensive in vitro and in vivo studies of the tribological problems, especially wear in artificial joints [3,6]. There are a number of important testing for this issue that can greatly affect a wear study in addition to the implant design and material selection [7].

Friction of Biomaterials

For example, about human lens depend on the shape and material properties of the lens, where the observation time is in minutes or hours, indicate that the stiffness of the lens increases with age at a faster rate in the lens centre than in the periphery. About hip prosthesis the frictional behavior of head coated with an oxide layer about 1-3 μm thick produced by induction heating can be expected to arise even under light pressures [8,9]. Recently fretting wear of Ti-6Al-4V flat against silicon nitride (Si3N4) ceramics ball using a special rotational fretting wear test reported accumulation of plastic deformation within the center of wear scars in the gross slip conditions and different fretting regimes [10].

Toxicity of Biomaterials

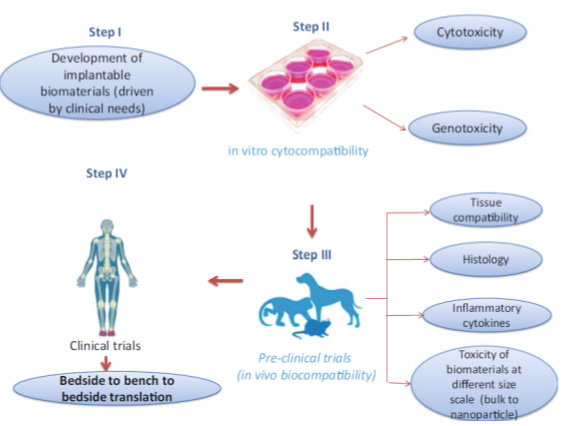

Understanding the phenomenon of the biological interaction of biomaterials an important aspect in evaluating the stability of an implant. As summarized in (Figure 2), the first stage involves the development of new implantable biomaterial involving processing, and physical and microstructural characterization and To avoid such anomalies, the potential toxicity in vitro and in vivo of a biomaterial should be evaluated before clinical use [11,12].

Improvement for Anti Tribological Deterioration

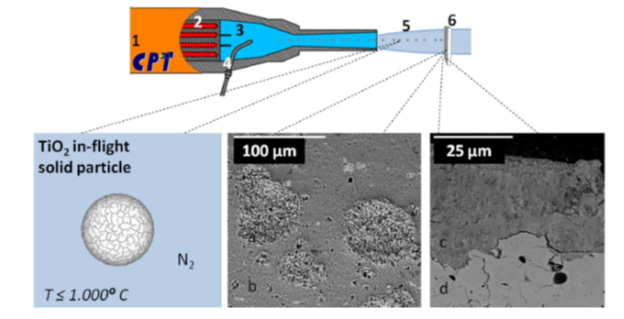

For improving the anti-tribological phenome, plasmaspray TiO2 coating was evaluated. Surface modification of biomaterials by conventional ion implantation and plasma immersion on implantation are innovative methods to improve the biocompatibility of these advanced materials. For example, biocompatibility improvements of Ti-6Al-4V with N and O is a conventional process [13-15] (Figure 3).

Figure 3: Scheme of a CGS gun, interaction between TiO2 particles and the nitrogen stream, and representative obtained coatings [13].

References

- Y Oshida (2010) Bioscience and bioengineering of titanium materials. Elsevier.

- A Bandyopadhyay, F Espana, V K Balla, S Bose, Y Ohgami, et al. (2010) Influence of porosity on mechanical properties and in vivo response of Ti6Al4V implants. Acta biomaterialia 6 (4): 1640-1648.

- J H Dumbleton (1981) Tribology of natural and artificial joints. Elsevier.

- M B Coventry (1975) Treatment of infections occurring in total hip surgery. Orthopedic Clinics of North America 6(4): 991-1003.

- V L Popov, A M Poliakov, V I Pakhaliuk (2021) Synovial joints. Tribology, regeneration, regenerative rehabilitation and arthroplasty. Lubricants 9(2): 15.

- L Kunčická, R Kocich, T C Lowe (2017) Advances in metals and alloys for joint replacement. Progress in Materials Science 88: 232-280.

- M Merola, S Affatato (2019) Materials for hip prostheses: a review of wear and loading considerations. Materials 12(3): 495.

- K Wang, B K Pierscionek (2019) Biomechanics of the human lens and accommodative system: Functional relevance to physiological states. Progress in Retinal and Eye Research 71: 114-131.

- D J Bartolovic (2005) In Vitro Wear Characterization on Ti-6A1-7Nb for Dental Prostheses Against High-fusing Porcelain. Indiana University School of Dentistry.

- V Clement, J Mo, M Zhu, M Shen, Z Zhou (2010) Research on the rotational fretting wear of Ti6Al4V alloy against silicon nitride. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology 224(11): 1181-1187.

- B Basu (2017) Probing Toxicity of Biomaterials and Biocompatibility Assessment. Biomaterials for Musculoskeletal Regeneration Springer, pp. 291-351.

- C Sikalidis (2011) Advances in Ceramics: Electric and Magnetic Ceramics, Bioceramics, Ceramics and Environment. BoD–Books on Demand.

- M Gardon, J Guilemany (2014) Milestones in functional titanium dioxide thermal spray coatings: A review. Journal of Thermal Spray Technology 23(4): 577-595.

- C Díaz, J Lutz, S Mändl, J García, R Martínez, et al. (2009) Improved bio-tribology of biomedical alloys by ion implantation techniques. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms 267(8-9): 1630-1633.

- S Jiang, H Xie (2011) Tribological behaviour of plasma-spray TiO2 coating against metallic bearing materials under oil lubrication. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology 225(3): 128-138.

Mini Review

Mini Review