ABSTRACT

The results of the study of the effect of a different ratio of the grinding mixture of triticale grain and rye on the yield of tritical-rye intermediate milling products and the yield of triticale-rye flour are presented. Grinding of the initial samples of triticale grain was carried out at laboratory grinding mills (MLP-4) with rifled (for dredged systems) and micro-rough rollers (for grinding systems). The mechanical and kinematic parameters of the threaded rollers of the MILL MLP-4 are as follows: the location of the grooves - the back along the back, the speed of the fast-rotating roller - 5 m / s, the differential - 1.5, the number of grooves per 1 cm - 8, the slope of the grooves - 7%. It was found that the greatest yield of intermediate grinding products from the presented samples was obtained from the control grain triticale, which amounted to 87.9%, including 14.2% of triticale flour. The lowest yield of intermediate grinding products was obtained from the control grain of rye, which is 81.9%, including 22.4% rye flour. It was revealed that when 50% of rye grain was added to the grinding triticale-rye grain mixture, the yield of intermediate grinding products in the form of groatstunst products was 83.1%, including 19.1% triticale-rye flour, when 40% of rye grain was added to the grinding triticale-rye grain mixture, the yield of intermediate grinding products in the form of groats tone products was 85.0%, including 17.3% triticale-rye flour, when 30% of rye grain was added to the grinding triticale-rye grain mixture.The yield of intermediate grinding products in the form of cereal products amounted to 87.9%, including 14.2% of triticale-rye flour. It was revealed that when grinding the initial control grain triticale, the yield of triticale flour was 77.9%, when grinding the initial control grain of rye, the yield of triticale flour accounted for 70.3%, which is 6.9% less than from triticale grain. When 50% of rye grain was added to the grinding triticale-rye grain mixture, the yield of triticale-rye flour was 72.9%, when 40% of rye grain was added to the grinding triticale-rye grain mixture, the yield of triticale-rye flour was 72.9%, when 30% rye grain was added to the grinding triticalerye grain mixture, the yield of triticale-rye flour was 77.1%. A direct dependence of the yield of triticale-rye flour on the content of rye grain in the grinding mixture was established. At the same time, it was revealed that the addition of rye grain to the grinding triticale-rye mixture leads to a decrease in the yield of triticale-rye flour.

Keywords: Triticale; Rye; Grinding Mixture; Intermediate Products of Grinding; Yield; Triticale-Rye Flour

Introduction

Triticale is a new type of cereal, the production and processing of which will contribute to solving the problem of expanding the range of bakery and flour confectionery products to meet the needs of the population in high-quality food products [1,2]. The chemical composition and biochemical properties of the triticale grain are typical for cereals such as wheat and rye, but the protein content exceeds, on average, by 2% the protein content in wheat grain and by 4% the protein content in rye and is at a level of more than 12%. In terms of fractional composition, the proteins of the triticale grain mainly occupy an intermediate position between the proteins of rye grain and wheat [3]. Existing traditional technologies for processing grain into food provide for mandatory technological operations, as a result of which biologically valuable anatomical parts of the grain are removed: the embryo, the aleurone layer and shells that are a source of dietary fiber, vitamins, minerals, protein substances, fats, which leads not only to a decrease in nutritional value, but also to the output of the finished product, and the operations themselves are characterized by high energy intensity. In the modern market of the grain processing industry, the range of grain processing products is represented mainly by various varieties of flour produced from wheat and rye [4,5]. Products of processing grain triticale and spelt are practically absent, since industrial technologies for processing these crops have not been developed. Triticale is used mainly for feed to farm animals in the form of grain mass, or feed based on triticale grain. Part of the triticale grain is also used in human nutrition. In Poland, 63% of the gross harvest of triticale goes to animal husbandry, 22% to bakery and confectionery production.

In Belarus, approximately 50% of triticale grain is consumed in animal husbandry and 50% in fermentation production for beer, alcohol [6,7]. In Russia, triticale is used mainly for the production of mixed fodder and ethyl alcohol. The use of triticale flour as a component of raw materials in the production of confectionery products: cookies, biscuits, muffins, crackers is promising. It is possible to use tritical flour in the production of quick breakfasts or in the manufacture of dietary varieties of bread. Bakery products from several cereals are becoming popular, including those using triticale [8,9]. The biochemical composition of the triticale grain is characterized by a high content of carbohydrates (68.8%) and proteins (12.8%), it contains 3.1% fiber, 2.0% ash and 1.5% fat. In terms of protein content, it surpasses not only rye grain, but also soft wheat grain [10,11]. (The endosperm of the triticale grain contains 27–28% water-soluble proteins, 7–8% salt-soluble, 25– 26% alcohol-soluble. The content of essential amino acids, such as lysine, valine, leucine, etc., is higher than in wheat, and the amount of the most important essential amino acid - lysine, significantly exceeds its content in wheat and is close to corn. Three-quarters of the weight of the triticale grain is starch with a low content of amylose (23.7%), in contrast to the starch of wheat and rye [12]. (The purpose of our research is to establish the influence of the different ratio of the grinding mixture of triticale grain and rye on the yield of tritical-rye intermediates of grinding and the yield of triticale-rye flour.

Materials and Methods of Research

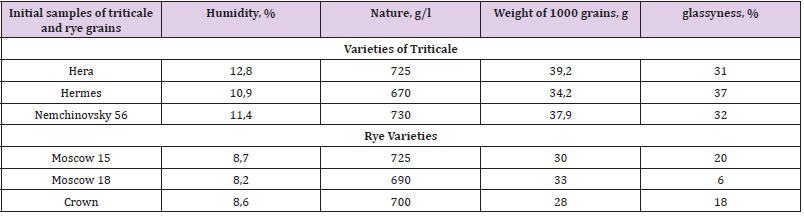

As an object of research, 3 varieties of winter triticale grains were used - Gera, Hermes, Nemchinovskaya 56 and 3 varieties of winter rye grain - Moskovskaya 15, Moskovskaya 18 and Krona of the harvest of 2021. The presented varieties of triticale and rye were bred by breeders of the laboratory of selection and seed production of field FGBNU “Federal Research Center “Nemchinovka”. The main physical and physicochemical indicators of the objects of study of the initial 3 varieties of triticale grain and 3 varieties of rye are presented in (Table 1). The study of the establishment of the effect of a different ratio of the grinding mixture of triticale grain and rye on the yield of tritical-rye intermediate milling products and the yield of tritical-rye flour was carried out according to the abbreviated laboratory technological scheme developed at the FSBEI HE “MGUPP” and including 5 deran and 5 grinding systems. Grinding of the initial samples of triticale grain was carried out at laboratory grinding mills (MLP-4) with rifled (for dredged systems) and micro-rough rollers (for grinding systems). The mechanical and kinematic parameters of the threaded rollers of the MILL MLP-4 are as follows: the location of the grooves - the back along the back, the speed of the fast-rotating roller - 5 m / s, the differential - 1.5, the number of grooves per 1 cm - 8, the slope of the grooves - 7%. Sieving of intermediate grinding products and sowing of flour was carried out on the sieving of the mill MLP-4, consisting of a set of 3 sieves, including 2 grits and one flour sieve. The inter-shaft clearance on the I drain system was 0.5 mm, on the II drana system - 0.25 mm, on the III drana system - 0.15 mm, on the IV dranaya system - 0.1 mm and V in the span system - 0.09 mm. As a hydrothermal treatment (GTO) in the preparation of a grinding grain triticale-rye mixture for laboratory grinding, cold conditioning was used as the most common method and the cheapest method.

Table 1: Physical and physico-chemical indicators of the quality of the initial samples of triticale and rye grain.

Results of the Study

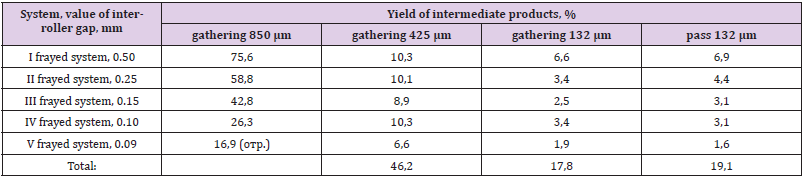

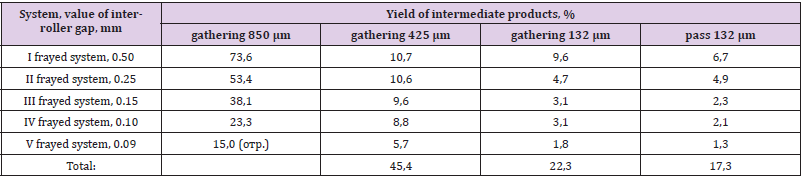

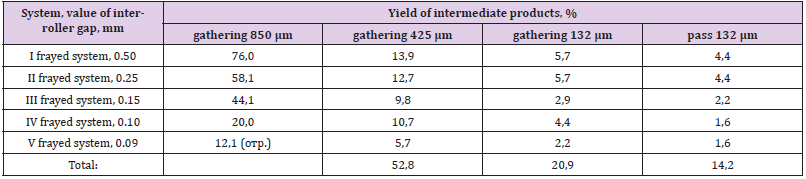

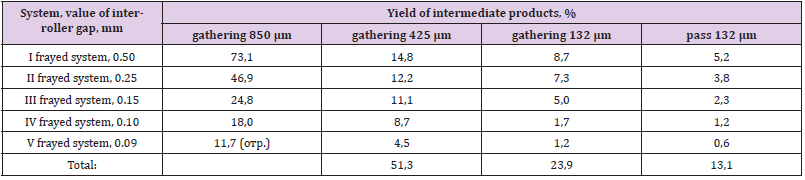

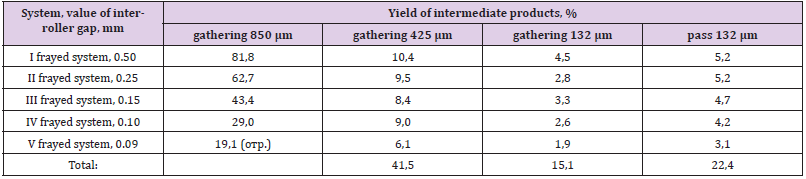

At the first stage of research to determine the effect of different ratios of the grinding triticale-rye mixture on the cereal-forming ability of intermediate grinding products, laboratory grindings of triticale-rye grain grinding mixtures were carried out in the ratios of 50/50%, 60/40%, 70/30% and control samples of the original triticale grain and rye. Preparation for laboratory grinding of tritical-rye grain grinding mixtures was carried out according to the previously established parameters of hydrothermal treatment [5]. During laboratory grinding of triticale-rye grain grinding mixtures, all 5 dredged, cereal-forming systems were modeled. Table 2 presents the obtained experimental data on the yield of intermediate grinding products and triticale-rye flour during grinding of triticale-rye grain grinding mixture in the ratio of 50%:50%. As can be seen from (Table 2), when 50% of rye grain was added to the grinding triticale-rye grain mixture, the yield of intermediate grinding products in the form of cereal products was 83.1%, including 19.1% of triticale-rye flour (Table 3). presents the experimental data obtained on the yield of intermediate grinding products and triticale-rye flour during grinding of triticale-rye grain grinding mixture in the ratio of 60%:40%. As can be seen from (Table 3), when 40% of rye grain was added to the grinding triticalrye grain mixture, the yield of intermediate grinding products in the form of cereal products was 85.0%, including 17.3% of triticalerye flour. (Table 4) presents the experimental data obtained on the yield of intermediate products of grinding and tritical-rye flour during grinding of tritical-rye grain grinding mixture in the ratio of 70%:30%.As can be seen from Table 4, when 30% of rye grain was added to the grinding triticale-rye grain mixture, the yield of intermediate grinding products in the form of cereal products was 87.9%, including 14.2% of triticale-rye flour(Table 5). presents the experimental data obtained on the yield of intermediates of grinding and tritical flour from the control grain triticale. As can be seen from Table 5, when grinding the control grain triticale, the yield of intermediate grinding products in the form of cereal products was 87.9%, including 14.2% triticale flour (Table 6). presents the experimental data obtained on the yield of intermediate products of grinding and triticale flour from the control grain of rye.

Table 2: Yield of intermediate products of grinding triticale-rye grain grinding mixture in the ratio of 50%:50%

Table 3: Yield of intermediate products of grinding triticale-rye grain grinding mixture in the ratio of 60%:40%.

Table 4: Yield of intermediate products of grinding triticale-rye grain grinding mixture in the ratio of 60%:40%.

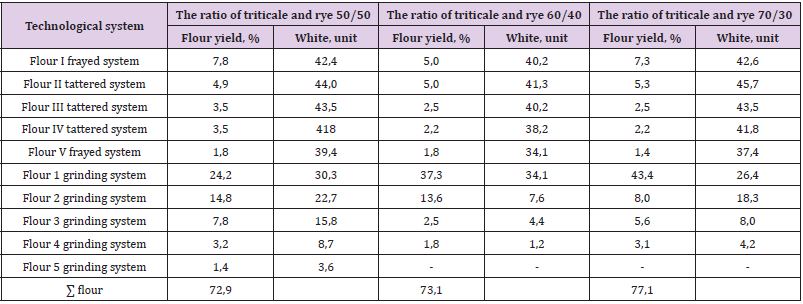

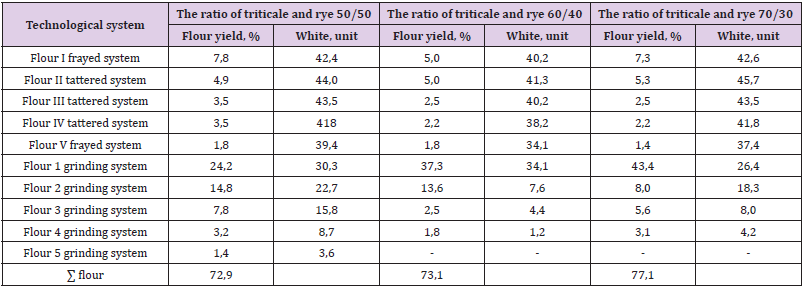

As can be seen from (Table 6), when grinding the control grain of rye, the yield of intermediate grinding products in the form of cereal products was 81.9%, including 22.4% of triticale flour. Thus, the largest yield of intermediate grinding products from the presented samples was obtained from the control grain triticale, which amounted to 87.9%, including 14.2% of triticale flour. The lowest yield of intermediate grinding products was obtained from the control grain of rye, which is 81.9%, including 22.4% rye flour. At the second stage of the research, comparative laboratory grindings of triticale-rye grinds of different ratios were carried out in comparison with control samples of triticale and rye with the determination of the yield and whiteness of individual flour flows from all 10 technological systems. The results are presented in (Tables 7 & 8). As can be seen from (Table 7), when 50% of rye grain was added to the grinding triticale-rye grain mixture, the yield of triticale-rye flour was 72.9%, when 40% of rye grain was added to the grinding triticale-rye grain mixture, the yield of triticale-rye flour was 72.9%, when 30% rye grain was added to the grinding triticale-rye grain mixture, the yield of triticale-rye flour was 77.1%. As can be seen from Table 8, when grinding the original triticale control grain, the yield of triticale flour was 77.9%, when grinding the initial control grain of rye, the yield of triticale flour was 70.3%, which is 6.9% less than from triticale grain.

Table 7: Yield and whiteness of triticale-rye flour flows of various ratios from all technological systems.

Table 8: Yield and whiteness of flour flows from the control grain of triticale and rye from all technological systems.

Conclusion

a) Thus, according to the results of the conducted studies, it was established that the greatest yield of intermediate grinding products from the presented samples was obtained from the control grain triticale, which amounted to 87.9%, including 14.2% of triticale flour. The lowest yield of intermediate grinding products was obtained from the control grain of rye, which is 81.9%, including 22.4% rye flour.

b) It was established that when 50% of rye grain was added to the grinding triticale-rye grain, the yield of intermediate grinding products in the form of cereal products was 83.1%, including 19.1% of triticale-rye flour, when 40% rye grain was added to the grinding triticale-rye grain mixture, the yield of intermediate grinding products in the form of groats tone products was 85.0%, including 17.3% triticale-rye flour, when added to the grinding triticale-rye grain mixture of 30% grain The yield of intermediate grinding products in the form of cereal products was 87.9%, including 14.2% of triticale-rye flour.

c) It was revealed that when grinding the initial control grain of triticale, the yield of triticale flour was 77.9%, when grinding the initial control grain of rye, the yield of triticale flour was 70.3%, which is 6.9% less than from the triticale grain. When 50% of rye grain was added to the grinding triticale-rye grain mixture, the yield of triticale-rye flour was 72.9%, when 40% of rye grain was added to the grinding triticale-rye grain mixture, the yield of triticale-rye flour was 72.9%, when 30% rye grain was added to the grinding triticale-rye grain mixture, the yield of triticale-rye flour was 77.1%.

d) A direct dependence of the yield of triticale-rye flour on the content of rye grain in the grinding mixture has been established. At the same time, it was revealed that the addition of rye grain to the grinding triticale-rye mixture leads to a decrease in the yield of triticale-rye flour.

References

- Vitol IS, Meleshkina EP, Kandrokov RKh, Verezhnikova IA, Karpilenko GP (2017) Features of the biochemical composition of triticale flour of different varieties. Storage and processing of grain 2: 30-32.

- Vitol IS, Meleshkina EP, Kandrokov RKh, Verezhnikova IA, Karpilenko GP (2016) Biochemical characteristics of new varieties of triticale flour. Bread products 2: 42-43.

- Vitol IS, Meleshkina EP, Kandrokov RKh (2016) Triticale grain processing products as an object for enzymatic modification. Storage and processing of agricultural raw materials 9: 14-16.

- Kandrokov RKh, Starichenkov AA, Steinberg TS (2015) Influence of TRP on the yield and quality of triticale flour. Bakery products 1: 64-65.

- Kandrokov RKh, Pankratov GN (2017) Technology for processing triticale grain into semolina-type grits. Bakery products 1: 52-54.

- Meleshkina EP, Pankratov GN, Pankratieva IA, Chirkova LV, Kandrokov RKh, et al. (2018) Triticale (processing technologies). Monograph (edts.)., EP Meleshkina. M FLINTA Publishing House, Russia, pp. 188.

- Pankratov GN, Meleshkina EP, Kandrokov RKh, Vitol IS (2016) Technological properties of new varieties of triticale flour. Bread products 1: 60-62.

- Pankratov GN, Kandrokov RKh, Shcherbakova EV (2016) Triticale grain grinding process. Bakery products 10: 59-62.

- Tulyakov DG, Meleshkina EP, Vitol IS, Pankratov GN, Kandrokov RKh (2017) Evaluation of the properties of flour from triticale grains using the Mixolab system. Storage and processing of agricultural raw materials 1: 20-23.

- Shubina LN (2007) Formation and evaluation of consumer properties of triticale grain flour using biological products. Abstract dis. In: Ph.D. Krasnodar (Eds.).,

- Kandrokov RH, Pankratov GN, Meleshkina EP, Vitol IS, Tulyakov DG, et al. (2019) Effective technological scheme for processing triticale grain into high-quality baker’s grade flour. Foods and Raw Materials 7(1): 107-117.

- Meleshkina EP, Pankratov GN, Vitol IS, Kandrokov RH, Tulyakov DG, et al. (2017) Innovative trends in the development of advanced Triticale grain processing technology. Foods and Raw materials 5(2): 70–82.

Research Article

Research Article