ABSTRACT

The results of studies of the effect of abrasive peeling on the yield of intermediate products of grinding a hulled wheat-triticale grain mixture during varietal bakery grinding are presented. A distinctive feature of the research objects was that the initial samples of the wheat-triticale grain mixture were passed through a peeling machine with. removal from 2.5% to 10% of fruit and flower shells. Due to the fact that the original samples of the wheat-triticale grain mixture were subjected to preliminary abrasive peeling, the total extraction of intermediate grinding products and flour on I-IV torn systems was increased and amounted to more than 85%. It has been established that abrasive peeling with the removal of up to 10% of the shells of wheattriticale grain mixtures before grinding into varietal baking flour has a positive effect on the coarse-forming ability and leads to an increase in the yield of intermediate coarse-grained products of grinding and an increase in the yield of flour on tattered systems. The highest yield of intermediate grinding products during processing of the initial wheat-triticale grain mixture is obtained when 10% of the shells are removed and is 82.8%, which is 6.9% more compared to the original non-hulled wheat-triticale grain mixture.

Keywords: Wheat-Triticale Grain Mixtures; Hulling; Yield; Grinding Intermediate Products; Flour

Introduction

The actual directions of development of one of the most important branches of the processing industry - flour milling - are both the improvement of technologies for processing traditional crops (wheat and rye) and the development of new technologies for processing non-traditional crops, such as triticale [1-7]. One of the main areas of development of the industry is the development of new and improvement of traditional technologies and the creation of processed products of various types of grain with a given composition and properties, incl. and products of deep processing [8-12]. In addition, the direction of joint processing of grain of various crops, including those based on wheat and triticale, is very promising. Triticale is the first grain crop created by man and obtained by crossing wheat (lat. Triticum) and rye (lat. Secale). The use of triticale as a food crop is an interesting, promising direction not only for flour milling, but also for other food and processing industries. This is confirmed by the increased interest in this culture, both on the part of researchers and food producers, not only in our country, but also abroad. Bakery products with the use of processed products from the central part of the triticale grain endosperm are characterized by increased nutritional value due to a higher content of protein and essential amino acids the main limiting acid, lysine [13-16]. The combination of the positive properties of rye - a high content of biologically active aromatic substances and wheat - the rheological properties of the dough, make it possible to produce food products of mass consumption from triticale grain processing products and mixtures based on it. At the same time, the technological properties of baking flour obtained from various grain mixtures, including wheat-triticale grain grinding mixture, remain little studied. Peeling of the wheattriticale grain mixture during varietal bakery grinding is carried out to maximize the cleaning of the grain surface from dust, dirt, mold, bacteria, as well as to reduce and simplify the length of the technological scheme [1-3]. Removal of surface shells with the use of shelling machines allows, in addition, to reduce the number of torn and grinding systems and to shorten the technological process of processing the grinding wheat-triticale grain mixture into flour.

When using abrasive peeling in the finished product, the number of shell particles decreases, and its appearance improves [1-2]. The ash content of the grinding grain mixture of wheat and triticale after peeling is reduced.

Removing shells allows you to:

1. Get a more solid and hygienic clean product.

2. To receive baking flour with a higher whiteness index from tattered systems.

3. Significantly reduce the number of grinding and sieve systems, simplify the technological scheme of grinding.

In addition, it should be noted that in the process of peeling, not only impurities are removed from the surface of the grain, but also part of the fruit and seed coats. This, on the one hand, has a positive effect on reducing the grain moisture process, but on the other hand, due to the exposure of the endosperm and injury to the grain germ, it can lead to the loss of its viability, which is not given enough attention. In this regard, additional studies of the peeling process and its effect on the properties of wheat grain are required [3]. The purpose of our research is to determine the effect of abrasive peeling on the yield of intermediate grinding products and flour during the processing of a hulled wheat-triticale grain mixture with varietal bakery grinding.

Materials and Methods of Research

In studies conducted at the Department of “Grains, Bakery and Confectionery Technologies” of the Federal State Budgetary Educational Institution of Higher Education “MGUPP” and at the Department of Food Technologies and Restaurant Business Organization at the Oryol State University. I.S. Turgenev conducted experiments to determine the effect of the degree of peeling of the wheat-triticale grain mixture on the yield of intermediate grinding products. The objects of research were the wheat variety “Radmira” and the triticale variety “Nemchinovsky 56”, bred by the breeders of the Federal State Budgetary Scientific Institution “Federal Research Center “Nemchinovka” and differing from other wheat varieties in the increased protein content of the 2020 harvest. The main physicochemical and chemical parameters of the initial wheattriticale grain mixture are as follows: moisture content - 11.2%, ash content - 1.83%, protein content - 13.2%, gluten content - 23.8%, gluten quality - 79 units device, glassiness - 46% and the falling number - 354 seconds. When preparing a wheat-triticale grain mixture for laboratory grinding as a hydrothermal treatment (HTT), a mandatory operation for varietal grinding, cold conditioning was used as the most common method and the cheapest way. After hydrothermal treatment, before grinding wheat-triticale grain mixtures, abrasive peeling was carried out. For grinding, an MLP-4 laboratory grinding mill with cut rollers with back-to-back corrugations was used.

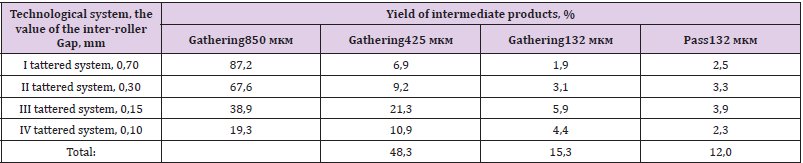

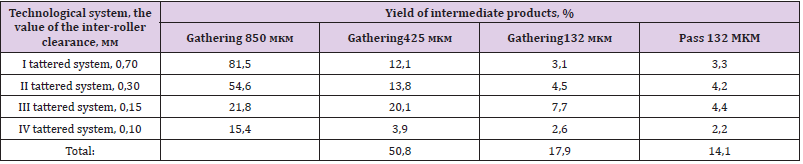

The main mechanical and kinematic indicators of the MLP-4 mill with cut rollers are as follows: productivity - up to 100 kg / h, the speed of the rapidly rotating roller is 4.5 m/s, the differential is 1.75, the location of the flutes is back-to-back, the number of flutes per 1 linear centimeter is 8 pieces, the slope of the flutes is 8%. The gap between the rollers on the I torn system was 700 μm, on the II torn system - 300 μm, on the III torn system - 150 μm and on the IV torn system - 100 μm. When conducting research to determine the effect of the number of shells removed during abrasive peeling of wheat-triticale grain mixtures on the yield of intermediate grinding products, laboratory grinding of shelled wheat-triticale grain mixtures was carried out with preliminary removal of shells in the amount of 2.5%, 5.0%, 7, 5%, 10% and control sample without peeling. Further, laboratory grinding was carried out and 4 out of 5 main, groat-forming tattered systems were modeled when grinding the initial wheat-triticale mixture and hulled wheat-triticale grain mixtures. The data obtained to determine the effect of abrasive hulling on the grain-forming ability of hulled wheat-triticale grain mixtures are presented in (Tables 1-5). As can be seen from (Table 1), the yield of intermediate products of grinding during the processing of the original wheat-triticale grain mixture without peeling, sent for grinding-to-grinding systems, was 63.6%, the yield of wheat-triticale flour was 12.0%, the yield of the end product sent on the V tattered system, amounted to 19.3%.

Table 1: Yield of intermediate products of grinding and flour of the initial wheat-triticale grain mixture without peeling.

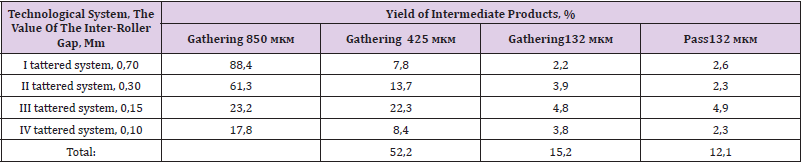

Table 2: The yield of intermediate products of grinding and flour during the processing of hulled wheat-triticale grain mixtures with the removal of 2.5% of the shells.

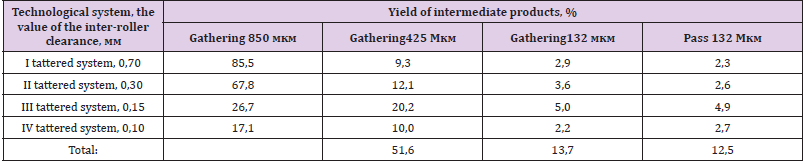

Table 3: The yield of intermediate products of grinding and flour during the processing of hulled wheat-triticale grain mixtures with the removal of 5.0% of the shells.

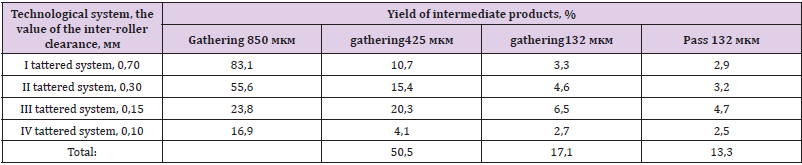

Table 4: The yield of intermediate products of grinding and flour during the processing of hulled wheat-triticale grain-mixtures with the removal of 7.5% of the shells.

Table 5: The yield of intermediate products of grinding and flour during the processing of hulled wheat-triticale grain mixtures with 10% shell removal.

As can be seen from (Table 2), the yield of intermediate products of grinding during the processing of hulled wheattriticale grain mixture with the removal of 2.5% sent for grindingto- grinding systems was 67.4%, the yield of wheat-triticale flour was 12.1%, the yield of of the product sent to the V torn system amounted to 17.8%. As can be seen from (Table 3), the yield of intermediate products of grinding during the processing of hulled wheat-triticale grain mixture with the removal of 5.0%, sent for grinding-to-grinding systems, was 65.3%, the yield of wheattriticale flour was 12.5%, the yield of of the product sent to the V torn system amounted to 17.1%. As can be seen from (Table 4), the yield of intermediate products of grinding during the processing of hulled wheat-triticale grain mixture with the removal of 7.5%, sent for grinding-to-grinding systems, was 67.6%, the yield of wheat-triticale flour was 13.3%, the yield of of the product directed to the V torn system amounted to 16.9%. As can be seen from (Table 5), the yield of intermediate products of grinding during the processing of hulled wheat-triticale grain mixture with the removal of 10.0%, sent for grinding-to-grinding systems, was 68.7%, the yield of wheat-triticale flour was 14.1%, the yield of of the product directed to the V torn system amounted to 15.4%. Thus, according to the results of the studies, it was found that the highest yield of intermediate products of grinding and flour during the processing of wheat-triticale grain mixture is obtained when 10% of the shells are removed and is 82.8%, which is 6.9% more compared to the original non-husked grain.

Conclusion

Thus, according to the results of the studies, it was found that abrasive peeling with the removal of up to 10% of the shells of wheat-triticale grain mixtures before grinding into varietal baking flour has a positive effect on the grain-forming ability and leads to an increase in the yield of intermediate coarse dunst products of grinding and an increase in the yield of flour on torn systems. The highest yield of intermediate products of grinding and flour during processing of the initial wheat-triticale grain mixture is obtained by removing 10% of the shells and is 82.8%, which is 6.9% more compared to the original non-hulled wheat-triticale grain mixture.

References

- Kandrokov RKh, GN Pankratov (2013) The role of peeling in the technology of processing grain of durum wheat. Bread products 3: 44-45.

- Kandrokov R Kh, Pankratov G N, Meleshkina E P, Vitol I S, Tulyakov D G (2019) Effective technological scheme for processing grain triticale grain into high quality baker’s grade flour. Foods and Raw Materials 7(1): 107-117.

- Kandrokov R Kh, G N Pankratov (2017) Technology for processing triticale grains into semolina. Bakery products 1: 52-54.

- Kandrokov R Kh, G N Pankratov (2019) Development of an effective technological scheme for processing triticale grain into high-quality baking flour. Russian agricultural science 1(1): 62-65.

- Manley M, Mc Goverin C, Snyders F, Muller N, Botes W, et al. (2013) Near-infrared spectroscopy. Cereal Chem 90: 540-545.

- Meleshkina E P, Pankratov G N, Vitol I S, Kandrokov R Kh, Tulyakov D G (2017) Triticale Grain Processing Technology. Foods and Raw Materials 5(2): 70-82.

- Meleshkina EP, G N Pankratov, R Kh Kandrokov, Vitol I S (2017) Technological and biochemical indicators as components of the quality of triticale flour. Product quality control 2: 38-44.

- Andreev N R, V V Kolpkakova, V G Goldstein (2018) On the issue of deep processing of grain triticale. Food industry 9: 30-33.

- Grabovets A I, Krokhmal A V, Dremucheva G F, Karchevskaya O E (2013) Breeding of triticale for baking purposes. Russ Agric Sci 39(3): 197-202.

- He M L, McAllister T A, Hernandez Calva L M, Aalhus J L, Dugan MER, et al. (2014) Effect of dietary inclusion of triticale dried distillers. Meat Sci 97: 76-82.

- Pankratov G N, E P Meleshkina, R Kh Kandrokov, I S Vitol (2016) Technological properties of new varieties of triticale flour. Bakery Products 1: 60.

- Vitol I S, E P Meleshkina, R Kh Kandrokov, I A Verezhnikova, G P Karpilenko (2016) Biochemical characteristics of new varieties of triticale flour. Bread products 2: 42.

- E P Meleshkina, G N Pankratov, I A Pankratieva, L V Chirkova, R Kh Kandrokov, et al. (2018) Triticale (processing technology). Monograph In: E P Meleshkina (Edt.)., M Publishing house FLINT. 188.

- Pankratov G N, R Kh Kandrokov, E V Shcherbakova (2016) The process of grinding grain triticale. Bakery products 10: 59.

- Tulyakov D G, DG Tulyakov, E P Meleshkina, I S Vitol, G N Pankratov, et al. (2017) Evaluation of the properties of triticale grain flour using the Mixolab system. Storage and processing of agricultural products 1: 20-23.

- Vitol I S, E P Meleshkina, R Kh Kandrokov (2016) Triticale grain processing products as an object for enzymatic modification. Storage and processing of agricultural products 9: 14.

Research Article

Research Article