ABSTRACT

Materials used to make goods, which produce a large share of greenhouse gas (GHG) emissions, is considered one of the main causes of the actual global warming and climate changing. Thus, conservation, restoration, land management actions and the circular economy, considered indispensable for removing the carbon emissions ,offer a way to avoid the environmental disasters and increase resilience of the climate change. Addressing these issues requires a coordinated effort among suppliers, buyers, market makers, consumers and the other entities involved in creating and trading to address and avoid all the actual toxic air emissions. Thus investing in nature adopting the green economy has became a must of our society. The proposal to utilize the actual waste for producing biodegradable polymers to be used for making innovative goods and bioplastics is the topic of this paper.

Keywords: Waste; Pollution; Polysaccharides; Chitin Nanofibrils; Nano lignin; Environment; GHG; Green Economy; Circular Economy

Abbreviations: GHG: Greenhouse Gas; WHO: World Health Organization; CN: Chitin Nanofibrils; ECM: Extra Cellular Matrix

Introduction

Given the increasing global level of waste and pollution and

its detrimental effects on air, water and the human health, The

safeness environment became a mast for worldwide consumers

together with wellbeing and longevity [1,2]. It is to underline in fact

that according to the World Health Organization (WHO),every year

occurs 4.2 million deaths as a result to outdoor pollution (Figure1)

[3], also if it isn’t to be forgotten the indoor nanoparticulates

represented from 10.000 to 240.000 nanoparticles/ml air [4].

Thus, it has been estimated that in 2015,diseases caused by air

pollution had a cost of USD 3.8 trillion in 176 Countries .Moreover,

the COVID-19 pandemic ,ravaging the World and attacking societies

at their core by an high impact on health and the economy never

ever imagined until today, has further increased the need to adopt

a Green Circular Economy [5,6]. Therefore, It has became a painful

evidence the necessity to shift healthcare system away from

profiting, giving a much bigger role to wellness and wellbeing, thus

changing the actual way of living [7]. However, our future survival

will depend on a new alignment between healthcare/wealth and

the preservation of both Environment and Biodiversity [3,8].

The materials and energy actually used to make consumer and

commercial goods ,in fact, produce a large share of greenhouse gas

(GHG) emissions impacting the environment by global warming

and climate changing [9,10]. Therefore, the urgent necessity to

produce and consume biodegradable goods that, decomposed or

deconstructed into different materials, can easily be recycled and

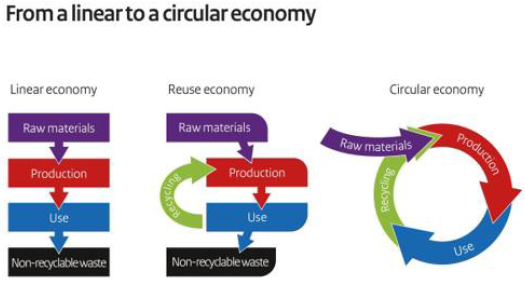

used without impacting the environment [10]. In conclusion the

Linear Economy, based on the taking, making and producing waste,

has to be changed by the Circular Economy of Reducing, Reusing

and Recycling (Figure 2). At this purpose many research studies

have been dedicated to emulate the productive strategies of nature

for making bio-based products from renewable feedstocks, without

waste and by a low consume of energy [5,6]. Thus, for example, both

cosmetic ingredients and packaging materials could be realized

by the use of biopolymers, involving the bacteria machinery to

make these products at zero waste, safe and inexpensive [11].

Consequently the new products of the circular economy might

be realized by the use of renewable sources and sustainable

technologies, possibly obtained from agroforestry or food waste,

such as chitin and lignin [12,13], preferably used in their nanosize,

such as chitin Nanofibrils (CN ) and Nanolignin (LG).

Chitin And Lignin for Innovative Tissues

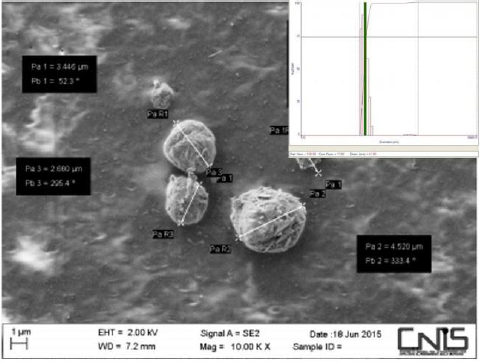

Both the natural polymers chitin and lignin, easily obtainable from food and agro-forestry waste at low cost, may be used as interesting biocompatible carriers to make smart particles and innovative biodegradable non-woven tissues for medical [14- 16] and cosmetic use [17-19], as well as to realize biodegradable films and nanocomposites for food packagings and cosmetic containers [20-22]. But how chitin and lignin can be used? Due to the fact that chitin is an electropositive polymer, while lignin has an electronegative backbone, they have been used to realize block polymeric particles by the gelation method (Figure 3). Successively, embedding the particles into a bio polymeric gel it has been possible to make tissues by the electrospinning technology or films by the casting technology. It is interesting to underline that these particles, more effective when in their nanosize, are able to encapsulate various active ingredients necessary to characterize the activity of the respective tissues and films [5,14-20] Thus, encapsulating nanoparticles made by nanostructured silver bound to fibers of chitin nanofibrils-chitosan ,it has been realized an innovative tissue that has shown an interesting anti-inflammatory and skin repairing activity both in vitro and in vivo [23-25].

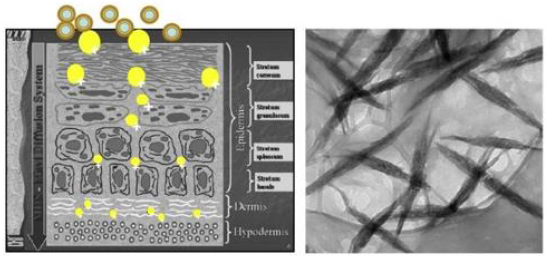

On the other hand, encapsulating other active ingredients such as vitamin A and E and nicotinamide and other compounds into the same tissue, innovative cosmeceuticals have been realized, effective to slow down the formation of fine lines and wrinkles and to repair the damaged hair, always respecting the environment [26-28]. However, it results important to underline that : polymer quality and purity ,method and size adopted to produce particles and complexes, quality and dose of the active ingredients selected and encapsulated, result fundamental to obtain effectiveness and safeness of the designed final product. Just to understand the importance of the polymer size it is to remember, for example, that small chitin (<40 micrograms) has shown an antiinflammatory activity, having on the other hand a pro-inflammatory activity with a size of 40-70 micrograms [29]. Moreover, the tissues and films possibilities to enter in contact with the right cells releasing the active ingredients at level of the different skin layers, depend not only to the polymeric fibers size, the electric charge of their surfaces and the pH of the environment, but first of all to the inter- fibrillar spaces necessary to permit the cell adhesion, proliferation and differentiation (Figure 4) [12,30]. However, the non-woven tissue, results effective to regenerate skin and other tissues when made by natural polymeric fibers reproducing the structure of the natural extra cellular matrix (ECM) [31].

Figure 4: Skin penetrability of Nanoparticles depends from their size, electrical charge and type of polymer but also from the tissue structure that has to be similar to native extra cellular matrix (ECM).

Conclusion

In a world where waste, pollution and carbon dioxide became a serious global threat to human health and the environment provoking many worldwide disasters, it results necessary to produce goods at zero waste by the use of bio-natural polymers and micro-nanoparticles, finally adopting the Circular Economy [13].The reported engineered micro-nano particles and tissues, in fact, could provide numerous advantages as green compounds characterized for their availability, reproducibility, biodegradability, renewability biocompatibility and non-toxicity. However due to their multi-functionality, these innovative biomaterials and carriers could represent active matrices effective to regenerate wounded, burned and aged skin as well as to make biotextiles for producing sportswear, biodegradable medical masks and other hygienic biomaterials or film-packagings to preserve food from bacterial contamination [5-7,12-28]. In any way, It is to underline that chitin, lignin and their complexes may be considered active carriers, being metabolized by the human enzymes to produce glucose, glucosamine, acetyl glucosamine and polyphenol compounds used from the cells as food or energy.

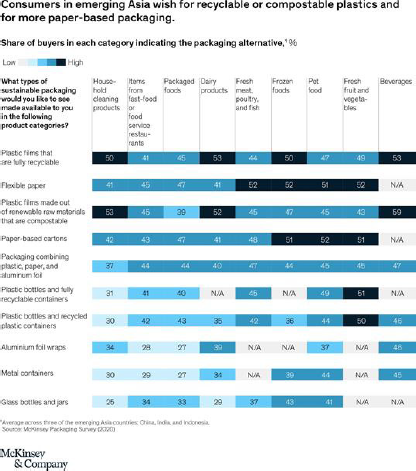

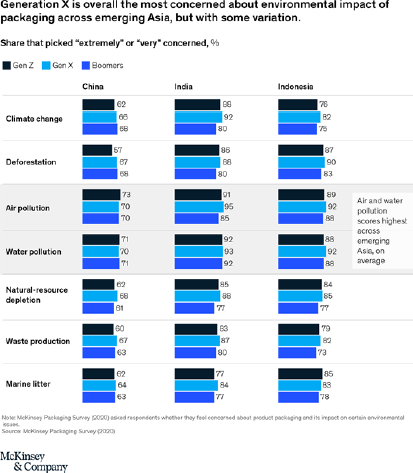

Additionally, it seems possible to stop the ocean’ mcroplastics waste, utilizing these biopolymers to produce the many plastic goods actually made by petrol-derived compounds. So doing it will be possible to avoid many toxic compounds dangerous for the algae, fish, sea mammals and birds as well as for the human health, because of their activity acting as endocrine disruptors for its content of toxic bis phenols [32]. For all these reasons the worldwide consumers, including Z Millennials (aged 18-34), Generation X (aged 35-50 ) and Baby boomers (51-69), request to prohibit the actual deforestation, eliminate air and water pollution and the natural resources depletion for the necessity to produce and consume, for example, recyclable or compostable packagings necessary to stop the climate change, as for our proposal. (Figure 5& 6) [33,34]. In conclusion ,natural climate solutions, that avoid GHG emissions and soil sequestration ,offer a way to limit warming and disasters by the worldwide introduction of the Green Economy.

Figure 5: Consumer request for environmental-friendly packagings (by courtesy of McKinsey & Company [33,34] ).

Figure 6: Request in Asia-Pacific for recyclable or compostable packagings (by courtesy of McKinsey& Company [33,34]).

References

- Reurbiesa J, Ruzgas I, Englom J, Holefors A (2018) The impact of pollution on skin. Cosmetics 5: 4.

- Puri P, Nandar SK, Kathuria S, Ramesh V (2017) Effects of air pollution on The Skin: A review. Indian J Dermatol Venereaol and Leprology 83(4): 415-423.

- Air pollution- Overview.2021 ,World Health Organization, United Nations, New York, USA.

- Nonynek GJ (2011) Nanotechnology and the skin: A Risk to human Health? In: Nanotechnology and Biotechnology in Cosmetics. proceedings, Milan.

- Morganti P (Ed) (2019) Bionanotechnology to Save the Environment. MDPI Editorial Office, Basel, Switzerland.

- Morganti P, Coltelli MB (Eds) (2021) An Introduction to the Circular Economy. NOVA Science Publishers, NY, USA ISBN: 978-1-53619-661-0.

- Morganti P (2016) Circular Economy: A New Horizon for Bio-Nanocomposites. Int J Biotech and Wellness Ind 5(4): 121-127.

- Rands MRW, Adams WM, Bennun L, Butchart SHM, Clemente A, et al. (2010) Biodiversity conservation: Challenges beyond 2010. Science 329: 1298-1303.

- Cooper P, Gibbs E, Mannion P Pinner D, Santoni G (2021) How Negative Emissions Can Help Organizations Meet Their Climate Goals. McKinsey and Company Report.

- Bissel J, Riley R, Eisemberg D (2021) Common goods: Fighting materials' Impact on climate change. McKinsey and Company Report

- Kawaguchi H, Ogino C, Kondo A (2017) Microbial Conversion of Biomass into Bio-based Polymers. Bioresources Technol 245:1664-1673.

- Morganti P (2016) Use of Chitin Nanofibrils from Biomass for an Innovative Bioeconomy. In :J Ebothe' and W Ahmed (Eds) Nanofabrication Using Nanomaterials. One Central Press, Manchester, UK, pp 1-22.

- Morganti P, Vannozzi A, Coltelli MB (2021) Chitin and Lignin Waste in The Circular Economy. In :P Morganti and MB Coltelli (Eds). An Introduction to the Circular Economy. NOVA Sciences Publishers ,NY,USA, pp 281-296.

- Morganti P, Danti S, Coltelli MB (2018) Chitin and Lignin to produce Biocompatible Tissues. Res Clin Dermatol 1(1): 5-11.

- Danti S, Trombi L, Fusco A, Azimi B, Lazzeri A, et al. (2019) Chitin Nanofibrils and Nanolignin as Functional Agents in Skin Regeneration. Int J Mol Sci 20: 266.

- Morganti P, Morganti G, Coltelli MB (2019) Chitin Nanomaterials and Nanocomposites for Tissue Repair. In: AH Choi and B Ben-Nissan (Eds)Marine-Derived Bionanomaterials for Tissue Engineering Applications 2019. Singapore, Springer, pp 523-544.

- Morganti P, Coltelli MB (2019) A New Carrier for Advanced Cosmeceuticals. Cosmetics 6:10.

- Morganti P, Morganti G, Colao C (2019) Biofunctional Textiles for Aging Skin. Biomedicines 7: 51.

- Morganti P, Morganti G, Coltelli MB (2020) Skin and Pollution: The Smart Nano-based Cosmeceutial-tissues to Save the Planet' Ecosystem. 2020.In:A Nanda, S Nanda, TA Nguyen, S Rajendran and Y Slimani (Eds)Nano cosmetics: Fundamentals, Applications and Toxicity, Elsevier, Amsterdam, Netherland, pp 287-304.

- Tischenko G, Morganti P, Stoller M, Kelnar L, Mikesova J, Koravova J, et al. (2019) Chitin Nanofibrils-Chitosan Composite Z Films:Characterization and Properties. In :P Morganti (Ed)Bionatechnology to Save the Environment MDPI, Basel, Switzerland, pp 191-226.

- Cinelli P, Coltelli MB, Signori F, Morganti P, Lazzeri A (2019) Cosmetic packaging to Save the Environment. Cosmetucs 6(2): 26.

- Coltelli MB, Aliotta L, Vannozzi A, Morganti P, Panaruello L, et al. (2020)Properties and Skin compatibility of Films Based on Poly(Lactic Acid)(PLA)Bionanocomposites Incorporating Chitin Nanofibriks(CN). J Funct Biomaterial 11: 21.

- Morganti P, Del Ciotto P, Stoller M, Chianese A (2016) Antibacterial And antiinflammatory Nanocomposites. Chem Eng Trans 47: 61-64.

- Donnarumma G, Fusco A, Morganti P, Pslombo M, Anniboletti T, et al. (2018) Advanced Medjcatiins made by Green Nanocomposites. Int J Res Nano Sci 5: 261-270.

- Anniboletti T, Palombo M, Moroni S, Bruno S, Palombo P, et al. (2019) Clinical Activity of Innovative Polymeric Nanoparticles and Non-woven Tissues. In: P Morganti(Ed) Green Bioeconomy and Bionanotechnology for a More Sustainable Environment MDPI, Basel, Switzerland, pp 340-360.

- Morganti P, Morganti G, Chen Hong-Duo(2020) Today Vision on Environment and Health. J Appl Cosmetol 38: 21-36.

- Morganti P, Morganti G, Gagliardini A, Lohani A (2021) From Cosmetics to Innovative Cosmeceuticals-non-Woven tissues as New Biodegradable Carriers. Cosmetics 8: 65.

- Morganti P, Morganti G, Coltelli MB (2021) Smart and Sustainable Hair Products Based on Chtin-derived Compounds. Cosmetics 8: 20.

- Lee CG, Da Silva CA, Lee JY, Z Hart LD, Elias JA (2008) Chitin Regulation of Z Immune Responses :An old Molecule with New Role. Curr Opin Immunol 20(6): 684-689.

- Morganti P, Carezzi F, Del Ciotto P, Morganti G, Nunziata ML, et al. (2014) Chitin Nanofibrils: A Natural Multifunctional Polymer. In: DA Phoenix and W Ahmed (Eds) Nanobiotechnology, 2014,One Central Press, Manchester, UK, pp 1-31.

- Morganti P, Fusco A, Paoletti I, Perfetto B, Del Ciotto P, et al. (2017) Antiinflammatory, Immunomodulatory, and Repair Activity on Human Keratinocytes by Green Innovative Nanocomposites. Materials 10: 843.

- Labor ER, Rahman MS, Ramani I (2015) A review on endocrine disruptors and their possible impact on human health. Environ Toxicol Pharmacol 40: 241-258.

- Erikson D, Lingquist O, Feber D, Nordigarden D, Granskog A. (2020) Sustainability in Packaging: Inside the Minds of Global Consumers. McKinsey & Company.

- Feber D, Kobeli L, Lingquist O, Nordigarden DM (2021) McKinsey on Packaging in the Next Normal. McKinsey & Company.

Short Communication

Short Communication