Abstract

Comfort is an important aspect especially in sports clothing, where the users perspire so much and sweat is in liquid moisture form. Clothing also influences an athlete’s physiology and performance during exercise. To determine the performance of various sportswear made of cotton and mostly used synthetic fibers (polyester, micro-polyester, channeled polyester, polyamide, and polyester/elastane) eight different athlete t-shirts were used in this experiment. Mechanical properties, air permeability, thermal resistance, and moisture management properties of the fabrics were measured. According to the results, it was determined that a very porous warp knitted structure has the highest Overall Moisture Management Capacity (OMMC) and air permeability, while it has the lowest thermal resistance. Cotton fabric has lower air permeability and bursting strength; however, it is a better heat insulator. In addition to this, since it is hydrophilic and absorbs water, it has been identified as “Good” in the case of moisture management property. Coolmax fabric has the highest maximum wetted radius, and it allows moisture to evaporate easier and provides quick drying.

Keywords: Sports Textile; Moisture Management; Sweat Transfer; Thermal Resistance

Introduction

Sport is an area that receives great attention and is subjected to a significant amount of investments. In the past years, the attraction towards sports and exercise has increased significantly. Thus, the number of people who exercise increased simultaneously. Considering its relevance to society and the economy, it is not surprising that other sectors are encouraged to develop innovative solutions in the area of sports [1,2]. This rise affected several sectors, especially in the textile sector. Sports clothing, shoes, and equipment have become a focus of textile companies. Therefore, many studies examine the innovations regarding this sector. In this research, the relationship between sports textile and sports performance is widely studied. The aim is to understand how various types of textile materials affect the performance and health of the athlete [3].

Sport Textile

Sport textile products include sports clothing, climbing ropes, parachute fabrics, sailing canvas, any type of shoes that are used during exercise such as running shoes, gym shoes, sleeping bags, ticking’s, etc. [4]. These products are expected to have certain standards in terms of adaptation to weather conditions, heatinsulation, water-resistance, comfort, flexibility, high-strength, air permeability, hygiene, dirt repellence, flame retardancy [2]. Therefore, the textile sector works to produce these in-demand types of fabrics [3]. In the textile sector, one of the basic factors while producing is to choose the right type of fabric, providing extra care for the features of fibers and the structure of the textile’s surface. Sport textile has a wide scope [5]. For instance, microfiber fabrics are quite in-demand today. This type of fabric contains a channeled structure and therefore provides good quality of air permeability [3]. Fabric type may easily affect the comfort and physiology of the person and lead to several problems such as excessive sweating, intense changes in body temperature, extra weight, inadequate protection against impacts, low resistance against water, low air permeability [2,6].

The characteristics of fabric in terms of fiber type and geometry may easily influence moisture evaporation [7]. Some studies analyze the factors that affect body heat while exercising [8]. Studies indicate that textiles that are hydrophilic (cotton etc.) have a positive effect in terms of balancing body heat. On the other hand, hydrophobic textiles (polyester, nylon, etc.) affect thermal comfort negatively during exercise [9]. However, after the development of channeled engineered fibers, synthetic fibers have a large application in comfortable clothes. Moisture transport properties of textiles are maintained by perspiring both in vapor and liquid form. Water vapor can pass through the fabric using diffusion, absorption, and desorption of vapor. Wetting and wicking are effective methods of liquid moisture transfer [10-12].

Fabrics and Sports Relation

When one exercises in an environment where the temperature is above average, heat is lost from the body through sweating. For this reason, the preservation of body temperature is quite essential during exercise [13]. The same principle is valid in environments with low temperature when the person who exercises uses special clothes to prevent heat loss [14]. Therefore, several studies may be found in the literature on sweating [15-21]. In terms of comfort provided by sports clothing, one can be affected in several ways: ergonomic, physiological, psychological, and skin-related [22,23]. Physiology may be affected by the type of fabric depending on thermal properties and permeability. Psychological effects are related to fashion and individual choices. Ergonomic comfort includes the ability to move without any restrictions to the body, depending on the elasticity of the clothing. Lastly, skin-related effects can be explained as the direct contact of fabric to the skin such as the softness of material [9]. The quality of sport cloth is directly linked to the comfort it provides to the athlete during exercise. Comfort is particularly an important issue since it directly influences the athlete’s performance and health. In case an athlete or anyone who exercises chooses a sports clothing with good air and moisture permeability, the person is expected to have a lower heart rate and body temperature compared to a person who chooses clothing with inadequate permeability [24-26]. Regarding the clear effect of sports clothing quality to sports performance and human health, it is important to use fabrics that have a good quality of air and moisture permeability and thermal features. There are various types of factors that affect the quality of clothing such as the structure of the fabric and the type of fiber that is used [9].

Thermal Comfort: The major benefit of sweating while exercising is heat preservation. The body can keep its temperature on a normal level through sweating. Body temperature maintenance is important to provide a balanced internal environment for all physiological systems to work. The mentioned situation is named heat acclimatization. Heat acclimatization decreases heat strain and also increases duration against heat [27]. Therefore, it provides thermal comfort for the body. However, when the moisture on the skin cannot be evaporated because of the covering sports clothing, this may cause the person to lose a greater amount of heat [28,29]. Therefore, it is important for the clothing to allow for air and water permeability. Otherwise, body temperature is expected to increase and result in thermal discomfort [30].

Water Loss: Water loss may be quite influential to the balance of the body affecting the thermoregulatory system, cardiovascular system, endocrine system, metabolic functions, etc. [31]. Water loss may impact athletic performance quite severely. Many studies in literature analyzed the relationship. According to some of the research, water loss does not influence athletic performance [32- 35]. However, other studies suggest otherwise, stating when water is lost from the body by 5% of the body weight, sports performance tends to be reduced [36,37]. Also, when water loss is 3% of body weight, muscle strength is expected to be decreased. Similarly, at a percentage of 2% or 3%, maximal aerobic power is affected negatively. In circumstances where the sports environment has a high temperature, the reductions in performance may be even higher [31,36]. In a textile preferable used for sport application, moisture and heat management are the key issues that have to be ensured for appropriate thermos physiological comfort [38]. The aim of this study is to investigate and compare the properties of different commercially available athlete fabrics.

Previous Studies: Several types of research have been made to understand how different fabrics that are used in sports clothing affect the human body during exercise. One study analyzed physiological aspects that can be influenced by the sports clothing using three types of fabric: 100% Tencel fibers, 100% polyester fibers, and a mix of both. According to the results, the mixed fabric type provided the best outcomes in terms of efficiency for the subjects [54]. Differences between the natural and synthetic types of fabrics and their effects on the regulation of body temperature are also analyzed in the literature. Some studies state that the fabric type that is used in the clothing is quite influential during exercise. When there is a more muscular activity, the body temperature rises [39,40].

Other than the specific issue of thermoregulation, many studies can be found on the influence of fabric type on heart rate, blood pressure, and oxygen level during exercise [41-45]. One research was conducted with the purpose to analyze the relationship between fabric type in sports clothing and thermal comfort people during sports. Subjects were asked to wear clothing with natural and synthetic fibers during and post- exercise [46]. After concluding the study, the researchers found out that cardiovascular and respiratory systems are highly affected by the material type. Another research also focused on the sports clothing fabric types’ of influences on athletes and their physiology. Volunteer athletes were asked to try three different sports clothing made of various types of fabrics: 100% cotton fibers, 35%/65% cotton-polyester mix fibers, and 100% polyester fibers. Different physiological parameters such as air permeability, moisture permeability, and thermal properties were studied. All three types of fabric demonstrated variating results on the subjects’ bodies and athletic performances. On the contrary to this present study, the researchers concluded that 100% polyester fabric provided better results in terms of physiology and performance [9].

Materials and Methods

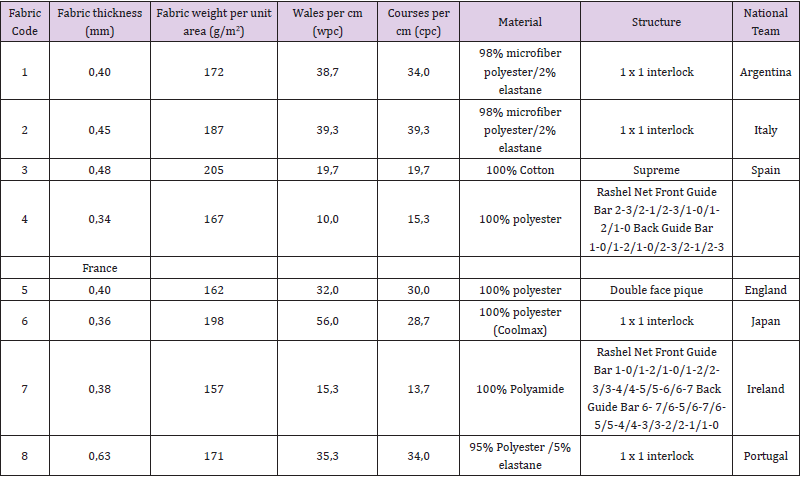

In this study, 8 different athlete t-shirts used in different national teams were used. They are summarized in (Table 1). They were obtained from an international supplier. After conditioning of the t-shirts for 24 hours under the standard atmosphere conditions (20 ± 2°C temperature and 65 ± 4% relative humidity), fabrics were tested for their physical properties. The structural properties of the fabrics are also given in (Table 1). Fabrics were produced from cotton, polyester, micro polyester, polyamide and polyamide/elastane yarns. The structural, mechanical and comfort characteristics of eight different fabrics were investigated. Mass per unit area was measured according to EN12127 standard, thickness was measured according to ISO 5084 standard. In order to determine mechanical performance of the fabrics, bursting strength values were measured according to ISO 13938-2 in 7.3 cm2 test area in Tru Burst Bursting tester. Air permeability tests were processed (by FX3300-Tester) according to ISO 9237 standard (Test area: 5 cm2, 100 Pa air pressure). Thermal resistance of the fabrics was tested according to ISO 11092 standard by using skin model. Thermal resistance, Rct, temperature difference between the two faces of a material divided by the resultant heat flux per unit area in the direction of the gradient [12]. The Moisture Management Tester (MMT) was used to test the liquid moisture management capabilities of textiles. It is designed to detect the liquid moisture transport properties in multiple directions [47,48].

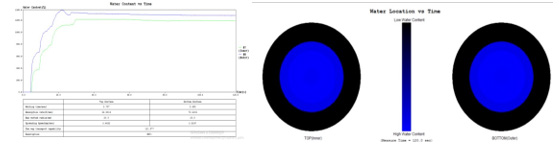

When moisture is transferred on fabric surface, the contact electrical resistance of the fabric changes and it changes according to two parameters: the components of liquid and the water content in fabric structure. Since the liquid properties are constant, the measured electrical resistance is associated with the water content in the fabric structure [49-51]. In order to simulate sweating, a special solution was prepared and is given onto the fabric. In this test design, the surface on which test liquid is dropped is designed as an inner surface that will be in contact with human skin surface. Overall Moisture Management Capacity (OMMC) is an index that is calculated by the instrument. It indicates the liquid transport properties of the fabrics. It is a key factor to indicate the overall capability of the fabric to manage the transport of liquid moisture [12,47,48,49,51]. When it is higher, the overall moisture management capacity of the fabric will be higher too.

Results and Discussion

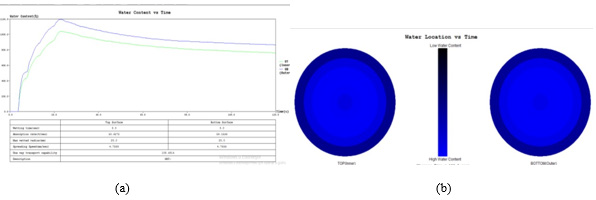

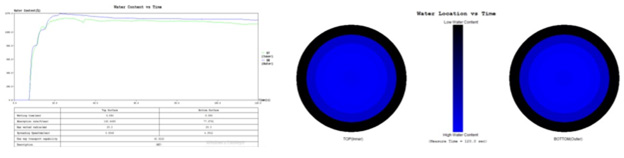

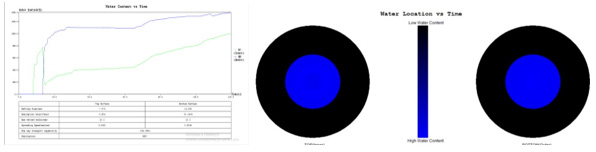

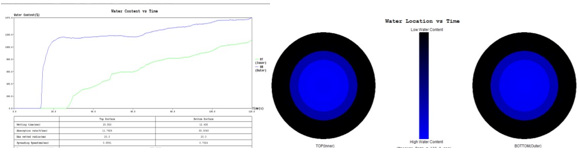

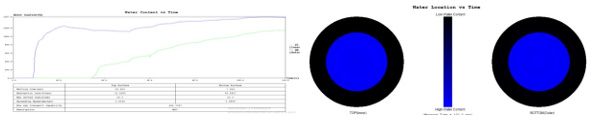

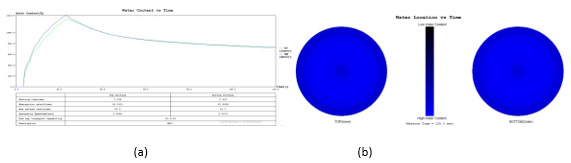

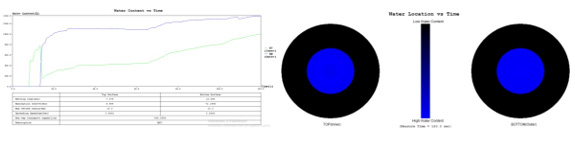

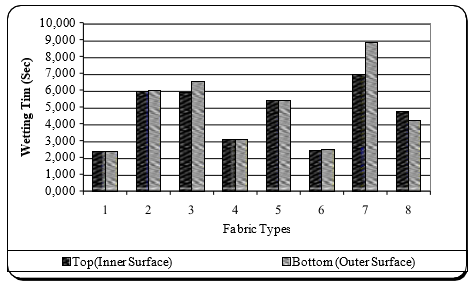

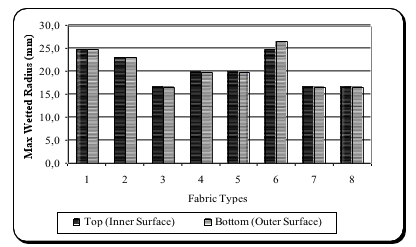

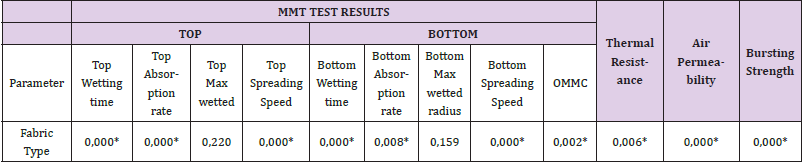

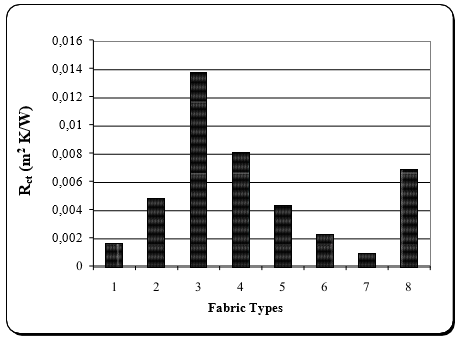

In order to determine whether the effects of fabric type on the measured parameters are significant or not, variance analysis were carried out and the p values are given in (Table 2). p values were examined according to the significance level of α = 0.05. Water content and water location vs. time graphics indicate water content change on face and bottom surfaces of the fabrics and total wetted areas after the measurement. The wetting times of the top and bottom surfaces of the tested double-faced fabrics are given in Figures 1- 9. Wetting time – WTT (top surface) and WTB (bottom surface) are the time period in which the top and bottom surfaces of the fabric just start to get wetted respectively after the test commences [47]. Maximum Wetted Radius (MWRtop and MWRbottom) are indicators of maximum wetted ring radius of top and bottom surfaces of the fabrics. Max Wetted Radius (mm) values of the test fabrics are given in Figure 5. According to Figure 10, Fabric 6 has the highest maximum wetted radius values, which means test liquid is transferred along the fabric easily. It is the result of the channeled fibers that increases the number of capillary channels between the fibers. Since liquid moisture is transferred along the fabric by capillary forces, Fabric 6 has the best performance among the investigated fabrics.

When microfibers are used in the structure, the fabric and fiber surface is enlarged; therefore, moisture is transported via more channels, since a better capillary effect is achieved [52]. For this reason, Fabric 1 and fabric 2 have high max wetted radius values. On the other hand, due to the hydrophilic character of cotton, some of the test liquid is absorbed by the cotton fibers, which results in lower moisture spreading along the fabric Spreading Speed (mm/ sec) is defined as the accumulative spreading speed from the center to the maximum wetted radius [43]. The accumulative spreading speed (SS) is calculated according to the given formula:

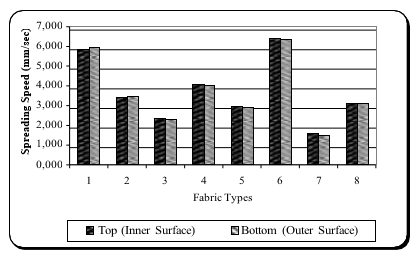

twrt and twrb are the times to reach the maximum wetted rings on the top and bottom surfaces, respectively [49]. Spreading speed test results are given in Figure 11. According to the results, it can be seen that Fabric 6 has the best performance, due to the channeled fibers in the structure. However, Fabric 7 has comparatively lower spreading speed value. Test liquid transferred by capillary forces between the synthetic fibers. Due to the very porous structure of the web, there is a smaller number of fibers that forms capillary tubes for moisture transfer. For this reason, low spreading speed value is measured. Fabric 3 (cotton) has also low spreading speed value. It is because of the hydrophilic characteristic of cotton, which quickly absorbs the water molecules, and it is entrapped in the structure. Thus, moisture transfer in the fabric direction is found comparatively lower. Spreading speed values of other fabrics were found between 2.8 mm/sec and 4 mm/sec.

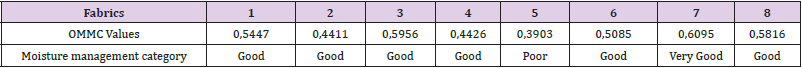

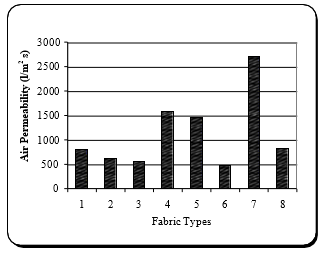

Overall Moisture Management Capacity (OMMC) is an index to indicate the overall capability of the fabric to manage the transport of liquid moisture, which is calculated by the software of the instrument [53]. According to the OMMC values of the fabrics (Table 3), fabric 7 has the highest value and identified as “very good”, due to its fabric construction. The dropped test liquid easily goes through the large pores of the fabric, and it increases OMMC value. It is followed by fabric 3, which is made of cotton and it is identified as “good” according to its overall moisture management property. Air permeability results are depicted in Figure 12. According to Figure 12, it can be seen that fabric 7, which has large pores in the structure, has the highest air permeability. Fabric 6, which has the highest density, has the lowest air permeability. Fabrics that have elastane yarn inside are tighter than the others and therefore they have low air permeability values. Cotton fabric, which is produced from staple fibers, has a hairy and thick structure and it causes low air permeability. Bursting strength values of the fabrics are given in Figure 13.

Table 3: OMMC values of test fabrics.

Evaluation: 0-0,2: Very poor, 0,2-0,4: Poor, 0,4-0,6: Good, 0,6-0,8: Very good, >0,8: Excellent.

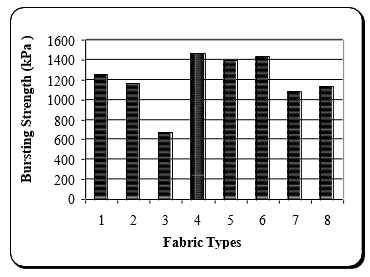

As it can be seen from the figure, fabric 3 (cotton fabric) has the lowest value, due the lowest fiber strength of cotton. Fabric 4, Fabric 5 and Fabric 6 have the highest values, which indicate that, these fabrics will reflect very good performance during the usage. It is a result of the 100% polyester fiber content in the fabrics. When elastane yarn is used in the structure, mechanical performance of the fabric decreases, however, fabric stretch ability increases. According, to the thermal resistance test results Figure 14, it can be depicted that, fabric 7 has the lowest thermal resistance, while fabric 3 has the highest. That means, thermal insulation of cottonbased fabric is the highest than all other samples. First reason of this is the staple fibers that create a hairy and bulky structure and, in this situation, entrapped still air inside the fabric is higher and this provides higher heat resistance. Secondly, thermal conductivity of cotton is 71 mW/m K, while it is 140 mW/m K for polyester fiber and 250 mW/m K for polyamide fiber [54]. For this reason, cotton material is less conductive, but more resistant to heat transfer. Large pores of Fabric 7 enable heat to transfer easily from one side to the other. Thus, in case of thermal resistance Fabric 7 has the lowest value.

Conclusion

Sports clothing is one of the factors that influence an athlete’s physiology and performance during exercise. Sports textile is a growing sector and offers several types of fabrics. In this concept, eight different athlete t-shirts, which are produced from cotton, polyester, micro-polyester, polyamide, and polyester/elastane were obtained and investigated for their moisture management, thermal and mechanical properties. Since synthetics have higher tensile strength than cotton fibers, all synthetic fabrics have higher bursting strength values than cotton fabric which means, they have good durability. However, in the case of comfort characteristics, the results are different. In the case of moisture management properties, fabric 7 and fabric 3 have high OMMC values, indicating that they have successful moisture management property. Fabric 7 is a warp knitted fabric and it has large pores inside that help liquid water to transfer. Cotton fiber has high water absorption capacity and is still used in different functional structures to maximize moisture transport properties. According to the results, it can be stated that water can be absorbed by cotton fabric (fabric 3) successfully and it is identified as “good” for moisture management property. Air permeability is related to the porosity of the structure and fabric 7 has the highest value for this reason. Fabric 3 (cotton fabric) and Fabric 6 which have the highest fabric density have low air permeability since they have low porosity and a more compact structure.

In the case of thermal resistance results, cotton fabric has the highest thermal resistance value, due to the low thermal conductivity and the entrapped air inside the fabric, which acts as a thermal barrier. However, Fabric 7 has the lowest thermal resistance. The porous structure of this fabric affects the thermal resistance and decreases its insulation property. The large pores increase liquid moisture, air, and heat transfer property. In conclusion, it was found that by using porous fabric constructions and synthetic fibers, air-permeable moisture management, thermally conductive and durable fabrics can be produced. In addition to this, nylon and polyester sports clothing work as an obstacle to the physiology and performance of athletes. However, cotton with its good moisture management property is still a suitable sportswear material and provides a quick sweat-absorbing property.

References

- Adolph EF (1947) Physiology of man in the desert. Interscience Publishers Inc., New York, USA. pp. 357.

- Ahlman K, Karvonen MJ (1961) Weight reduction by sweating in wrestlers, and its effect on physical fitness. J Sports Med Phys Fitness 1: 58-62.

- Akçalı K (2016) Spor tekstilleri üretiminde kullanilan farkli kumaş yapilarinin incelenmesi. Int J Sci Culture Sport 4(3).

- Akçalı K (2016) Teknik tekstillerin spor branşlarinda kullaniminin incelenmesi. Int J Sci Culture Sport 4(2): 533-546.

- Bosco JS, Terjung RL, Greenleaf JE (1968) Effects of progressive hypohydration on maximal isometric muscular strength. J Sports Med Phys Fitness 8(2): 81-86.

- Casa DJ (1999) Exercise in the heat. I. Fundamentals of thermal physiology, performance implications, and dehydration. J Athl Train 34(3): 246-252.

- Chowdhury P, Samanta KK, Basak S (2014) Recent development in textile for sportswear application. Int J Engg Res Technol 3(5).

- Ciesielska I, Mokwinski M, Orlowska Majdak M (2009) Influence of different kind of clothing material on selected cardiovascular, respiratory and psychomotor parameters during moderate physical exercise. Int J Occup Med Environ Health 22(3): 215-226.

- Cotter JD, Patterson MJ, Taylor NA (1995) The topography of eccrine sweating in humans during exercise. Eur J Appl Physiol Occup Physiol 71: 549-554.

- Das B, Das A, Kothari VK, Fanguiero R, Araujo M (2009) Studies on moisture transmission properties of PV-blended fabrics. In: The Journal of the Textile Institute 100(7): 588-597.

- Das B, Das A, Kothari VK, Fanguiero R, Araujo M (2007) Moisture transmission through textiles. Part I: processes involved in moisture transmission and the factors at play. In: AUTEX Research Journal. 7(2): 100-110.

- Davranche K, Audiffren M (2004) Facilitating effects of exercise on information processing. J Sports Sci 22(5): 419-428.

- Foster L (1998) Sportswear 2000-Interpreting fabric trends. World Sports Active Wear 4(3): 21-24.

- Gavin TP (2003) Clothing and thermoregulation during exercise. Sports Med 33(13): 941-947.

- Gavin TP, Babington JP, Harms CA, Ardelt ME, Tanner DA, et al. (2001) Clothing fabric does not affect thermoregulation during exercise in moderate heat. Med Sci Sports Exerc 33(12): 2124-2130.

- Gonzalez-Alonso J, Teller C, Anderson SL, Jensen FB, Hyldig T, et al. (1999) Influence of body temperature on the development of fatigue during prolonged exercise in the heat. J Appl Physiol 86(3): 1032-1038.

- Gülsevin N (2005) Spor Giysilerin Konfor Özellikleri Üzerine Bir Araştirma, Ege Üniversitesi Fen Bilimleri Enstitüsü (Yüksek Lisans Tezi), Bornova - Izmir.

- Gupta D (2011) Functional clothing-definition and classification. Ind J Fibre Textile Res 36: 321-326.

- Ha MA, Tokura H, Yoden K, Holmer I (1998) A comparison of skin temperatures and clothing microclimate during moderate intermittent exercise in the cold between one and two layers of cotton and polypropylene underwear. Int J Occup Saf Ergon 4: 347-362.

- Hassan M, Qashqary K, Hassan HA, Shady E, Alansary M (2012) Influence of sportswear fabric properties on the health and performance of athletes. Fibres and Textiles in Eastern Europe 4(93): 82-88.

- Hatch KL, Markee NK, Maibach HI (1992) Skin response to fabric a review of studies and assessment methods. Clothing Textiles Res J 10(4): 54-63.

- Havenith G, Fogarty A, Bartlett R, Smith CJ, Ventenat V (2008) Male and female upper body sweat distribution during running measured with technical absorbents. Eur J Appl Physiol 104(2): 245-255.

- Havenith G, Richards MG, Wang X, Brode P, Candas V, et al. (2008) Apparent latent heat of evaporation from clothing: attenuation and ‘‘heat pipe’’ effects. J Appl Physiol 104(1): 142-149.

- Heyward VH (2006) Advanced fitness assessment and exercise prescription. 5th Edition, Human Kinetics Publishers. Champaign, IL, USA.

- Hilper C, Elsner P (2006) Bio functional textiles and the skin. Karger AG, Basel: Switzerland. pp. 51-66.

- Hu J, Li Y, Yeung KW, Wong AS, Xu W (2005) Moisture management tester: a method to characterize fabric liquid moisture management properties. Textile Res J 75(1): 57-62.

- Ishtiaque SM (2000) Engineering comfort, proceedings on smart textiles, their production and market strategies. Eds: S Gupta. NIFT, New Delhi, India. pp. 58-64.

- Jeong YO, Tokura H, Zhang P (1996) Is endurance performance of handgrip exercise influenced by two different clothing ensembles? Appl Human Sci 15: 275-279.

- Li Y, Xu W, Yeung KW (2000) Moisture management of textiles. pp. 338.

- Lotens WA, Vandelinde FJ, Havenith G (1995) Effects of condensation in clothing on heat transfer. Ergonomics 38(6): 1114-1131.

- Machado-Moreira CA, Caldwell JN, Mekjavic IB, Taylor NA (2008) Sweat secretion from palmar and dorsal surfaces of the hands during passive and active heating. Aviat Space Environ Med 79(11): 1034-1040.

- Machado-Moreira CA, Smith FM, van den Heuvel AM, Mekjavic IB, Taylor NA (2008) Sweat secretion from the torso during passively-induced and exercise-related hyperthermia. Eur J Appl Physiol 104: 265-270.

- Machado-Moreira CA, Wilmink F, Meijer A, Mekjavic IB, Taylor NA (2008) Local differences in sweat secretion from the head during rest and exercise in the heat. Eur J Appl Physiol 104: 257-264.

- Moisture Management Tester Operation Manual.

- Nadel ER (1979) Control of sweating rate while exercising in the heat. Med Sci Sports 11: 31-35.

- Nguyen MH, Tokura H (2000) The different effects of black and white Vietnamese Aodai folk costumes on rectal temperature and heart rate in women walking intermittently in hot and sunny environment. Int J Occup Med Environ Health 13(1): 27-38.

- Özdil N, Anand S (2014) Recent developments in textile materials and products used for activewear and sportswear. Electro J Textil Technol 8(3): 68-83.

- Özdil N, Bahadır Ünal Z, Boz S, Süpüren Mengüç G (2014) Properties of the knitted upper clothes used by primary school children. Industria Textila 65(5): 287-293.

- Özdil N, Süpüren G, Özçelik G, Průchová J (2009) A study on the moisture transport properties of the cotton knitted fabrics in single jersey structure. Tekstilve Konfeksiyon pp. 218-223.

- Rupp J, Yonenaga A (2000) Microfibers-the new man-made fiber image. International Textile Bulletin 4. pp. 12-24.

- Saltin B (1964) Circulatory response to submaximal and maximal exercise after thermal dehydration. J Appl Physiol 19: 1125-1132.

- Sawka MN, Montain SJ, Latzka WA (1996) Body fluid balance during exercise-heat exposure. in: buskirk ew, puhl sm, eds. body fluid balance: exercise and sport. CRCPress, New York, USA, pp. 139-157.

- Shishoo R (2005) Textiles in sport. Woodhead Publishing Limited, pp. 177-202

- Smith CJ, Havenith G (2011) Body mapping of sweating patterns in male athletes in mild exercise-induced hyperthermia. Eur J Appl Physiol 111(7): 1391-1404.

- Spencer-Smith JL (1977) The physical basis of clothing comfort, part 4: the passage of heat and water through damp clothing assemblies. Clothing Res J 5: 116-128.

- Süpüren G, Oğlakçıoğlu N, Özdil N, Marmaralı A (2011) Moisture management and thermal absorptivity properties of double-face knitted fabrics. Textile Res J 81(13): 1320-1330.

- Taylor NA, Caldwell JN, Mekjavic IB (2006) The sweating foot: local differences in sweat secretion during exercise-induced hyperthermia. Aviat Space Environ Med 77(10): 1020-1027.

- Tortora PG, Collier BJ (1997) Understanding Textiles. Upper Saddle River. Prentice-Hall Inc, New Jersy, USA.

- Umbach KH (2001) Optimization of the wear comfort by suitable fiber, yarn and textile construction. 40th International Man Made Fibres Congress, Dornbirn, Austria.

- Umbach KH (2002) Measurement and evaluation of the physiological function of textiles and garments. 1st Joint conference ‘visions of the textile and fashion industry. Seoul, South Korea.

- Uttam D (2013) Active Sportwear Fabrics. Int J IT, Engg Appl Sci Res 2(1): 34-40.

- Webster S, Rutt R, Weltman A (1990) Physiological effects of a weight loss regimen practiced by college wrestlers. Med Sci Sports Exerc 22: 229-234.

- Zimniewska M, Huber J, Krucinska I, Torlinska T, Kozlowski R (2002) The influence of clothes made from natural and synthetic fibres on the activity of the motor units in selected muscles in the forearm-Preliminary studies. Fibres Textil Eastern Eur 39(4): 55-59.

- Zimniewska M, Laurentowska M, Bogacz E, Krysciak J, Domaszewska K, et al. (2008) Influence of Sportswear Made from Polyester and Man-Made Cellulosic Fibres on the Energy Cost of Physical Effort. Fibres and Textiles in Eastern Europe 3(80): 94-99.

Research Article

Research Article