Abstract

Polylactic-co-glycolic acid (PLGA) microparticles have attracted scientists and engineers from various research fields. PLGA microparticles have been extensively used for drug delivery since the synthesized polymer is FDA approved polymer. Here, we present a method to control the formation of PLGA microparticles. prose and the surface activation of microparticles. A series of nanoporous PLGA microparticles were synthesized with different surface porosity. The porosity agent concentration influenced the surface activation. Thus, nanoporous PLGA microparticle can be introduced as a new focused drug delivery platform. The porosity of the activated microparticles showed a direct relationship with the covalent attachment of Lysine primary amine molecule. The nanoporous PLGA microparticle synthesis is a fast and low-cost method. Furthermore, nanoporous PLGA microparticles are suitable for applications in targeting one or multiple extracellular ligands. In specific, cancer cell ion channels exist in the cell ‘s extracellular space and can be targeted without entering the target cells.

Keywords: Cell Targeting; PLGA; Ion Channels; Nanoporous; Target Delivery; Salt-Leaching.

Introduction

PLGA has been widely used for drug delivery and shown

significant improvement in therapeutic areas. PLGA blocks are

built from lactic and glycolic acid monomers that can be absorbed

by the cell. Therefore, PLGA is a non-immunogenic, non-toxic, and

stable polymer for the development of drug delivery. Furthermore,

hydrophilic and hydrophobic drug molecules, DNA, and proteins

can be encapsulated [1]. PLGA has an excellent biocompatibility

profile [2,3]; therefore, the encapsulated molecules achieved target

release profile through degradation and erosion of the polymer

matrix [4,5].

Nanotechnology offers unique and fascinating approaches

in the area of nanomedicine and healthcare application [6,7].

Nanoporous microparticles have been used for bioseparation,

drug release, and tissue engineering. In bioseparation, highly

nanoporous microspheres have been extensively commercialized in

chromatography [8-10]. In drug release, nanoporous microspheres

can be designed to be multifunctional carriers for efficiently loading

drugs [11,12]. The porous nanoparticles showed higher drug

loading and releasing over a period of 30 days from nonporous

nanoparticles [13]. In porous PLGA microparticles, autocatalytic

effects play an essential role in controlling the drug release. The

presence of the nanopores increases the drug molecules’ mobility

and altered the drug release mechanisms [14]. In tissue engineering

and regenerative medicine, nanoporous microspheres are one of

the best candidates for regenerative repair, and tissue engineering

[15,16]. These nanoporous microparticles show significant

advantages in many practical applications.

The primary aims of this study:

(i) Surface activate nanoporous PLGA microparticles (Figure 1),

specifically, the crosslinking of bis (sulfosuccinimidyl) suberate

(BS3) with primary amines to form amide bonds.

(ii) Characterize the effect of salt concentration on the formation

of nanoporous and microparticles porosity.

(iii) study the effects of the porosity on the covalent amide bond

formed between primary amine ligand and BS3 molecules.

We introduce a method that can be used to target extracellular ligand, such as cell ion channels. The channel blockers may crosslink to nanoporous PLGA microparticles and act like a cork in a bottle, preventing the flow of ions in targeted cells until it diffuses off gradually. A targeted cell approach blocking ion channels activity can provide controlled, and a better-tolerated treatment for patients.

Materials and Methods

Materials

All analytical grade reagents used in this work are purchased from Sigma-Aldrich (St. Louis, MO) unless noted otherwise. Poly (D, L-lactide-co-glycolide) 75:25 molar ratio with a carbocyclic group (uncapped) was obtained from Resomer® (Darmstadt, Germany). 1, 2-Dichloroethane (ACS reagent, ≥99%) polyvinylpyrrolidone (PVP-k90), Lysine, and sodium bicarbonate (NaHCO3) were purchased from Sigma-Aldrich (St. Louis, Missouri, USA). Micro BCA protein assay kit and bis (sulfosuccinimidyl) suberate (BS3) were purchased from Thermo-Scientific, Rockford, Illinois, USA.

Synthesis of Nanoporous PLGA Microparticles

PLGA microparticles were synthesized using a double emulsion

method [17]. First, 3% (w/v) of the PLGA solution was prepared by

dissolving PLGA in dichloroethane. Then, 0.2 mL of deionized (DI)

water was added to the PLGA solution and vortexed for 30 sec to

create a water-in-oil phase. A solution of 3%, 0.5%, and 0.1% (w/v)

of sodium bicarbonate in DI water were prepared. Then, the sodium

bicarbonate solution was added to the water-in-oil phase sample

to form nanoporous microparticles. Then, 5% of PVP-k90 solution

in DI water was prepared and two mg of BS3 dissolved in DI water

(100 μL) was added to PVP-K90 solution and vortexed for one

minute to ensure well mixing. The step of adding NaHCO3 solution

was skipped for the preparation of nonporous PLGA microparticles,

as shown by the schematic flowchart (Scheme 1). It was then added

dropwise to the stirring beaker of PVP-k90 solution. Table 1 shows

the prepared samples. Next, the solution vials were kept on stir plate

overnight in a chemical hood to allow dichloroethane to evaporate.

Once the dichloroethane evaporated entirely, the solution was

transferred into a 15 ml tube and centrifuged at 4000 rpm for 15

min. The pellets were collected and suspended in phosphate buffer

saline (PBS), then freeze-dried at -80 °C.

The freeze-dried microparticles were taken in a plastic tube,

washed with DI water, and centrifuged at 4,000 rpm for 15 min

three times to form nanoporous PLGA microparticles and remove

the trapped salt. Iterative washing in DI water after centrifugation

is known to remove the water-soluble salts completely [13, 18, 19].

The pellets were suspended in 5 mL PBS. ZetaPALS DLS detector

(Brookhaven Instruments, Holtsville, NY, USA) was used to measure

the size and polydispersity of microparticles

Scheme 1: Schematic flowchart for the procedure to synthesize nanoporous and nonporous microparticles. PLGA microparticles were synthesized using double emulsion method. DI water was added to PLGA solution and vortexed, then NaHCO3 was prepared and added to water-in-oil phase samples. The sample was added dropwise to solution of PVP-K90 with BS3. The sample was kept overnight on stir plate to complete the phase separation. Finally, the sample was washed with DI water to perform salt leaching step.

Preparation of Nanoporous PLGA Microparticles for Scanning Electron Microscope (SEM) Imaging

10 mg freeze-dried microparticles were suspended in 1.5 mL DI water; the sample was diluted for imaging in SEM. DI water was used instead of PBS to avoid crystallization and imaging artifacts stemming from the salts. The sample was sputter-coated with 50 Ǻ thick gold to prevent the surface from getting charged during SEM imaging. The thin layer of gold coating made sure that the glass coverslip surface was conductive enough to image with SEM.

Covalent Attachment of Lysine to Nanoporous PLGA Microparticles

The surface activated nanoporous PLGA microparticles were suspended in PBS for covalent attachment to Lysine. The microparticles underwent the process of conjugation, followed by PBS washing. For each sample in Table 1, 10 mg was suspended in 5 mL PBS, then 30 mg of Lysine was added to each sample and incubated for 30 min. The excess of Lysine was removed by centrifugation followed by PBS wash (x2) to obtain Lysine conjugated to nanoporous microparticles surface.

Results

Nanoporous PLGA Microparticle Morphology

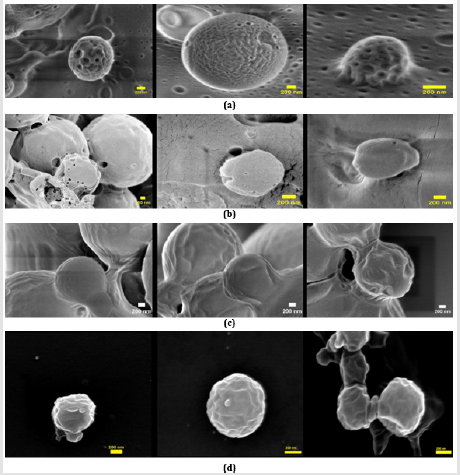

The shape of nanoporous PLGA microparticles is a critical feature in the success of targeting drug delivery [20]. Also, the shape of microparticle influences the surface area available for surface activation. Here, the nanoporous microparticles were prepared using the double emulsion method with NaHCO3 as the pores foaming agent. The morphology of synthesized nanoporous PLGA microparticles was found to be spherical from SEM micrographs (Figure 2). PLGA microparticles with large surface-to-volume ratios are preferred for targeting since sizable surfaces allow for the attaching of many ligands.

Figure 2: SEM images of 3% PLGA microparticles prepared using double emulsion method with different salt concentration. (a) 3% NaHCO3 (b) 0.5% NaHCO3 (c) 0.1% NaHCO3 (d) nonporous PLGA microparticles (Scale bar = 200 nm)

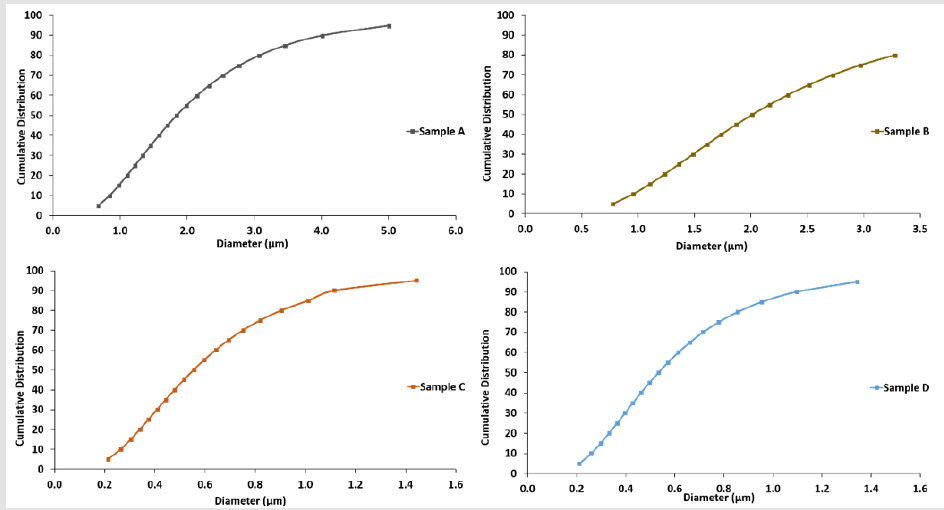

Nanoporous PLGA Microparticle Size

The size distribution of the microparticle samples was measured using a ZetaPALS DLS detector. The mean diameter of the nonporous PLGA microparticles was 0.60 ± 0.30 μm (polydispersity = 0.37). The diameter of nanoporous PLGA microparticles prepared with 0.1%, 0.5% and 3% NaHCO3 was 0.63 ± 0.32 μm (polydispersity = 0.40), 1.80 ± 0.66 μm (polydispersity = 0.40), and 2.11 ± 1.15 μm (polydispersity = 0.45), respectively. The mean diameter of the PLGA microparticles increased with the addition of NaHCO3. Figure 3 shows PLGA microparticle’s cumulative distribution vs. diameter of each sample.

Nanoporous PLGA Microparticle Porosity Analysis

PLGA microparticles samples porosity has been calculated using ImageJ software (National Institutes of Health, Bethesda, Maryland, USA). Using the analyze particles function within ImageJ, the percentage of pixels in the image have been highlighted by applying the built-in image threshold function (Table 2). Since the pores showed a different threshold than the background, porosity can be calculated in a very efficient technique (Figure 4).

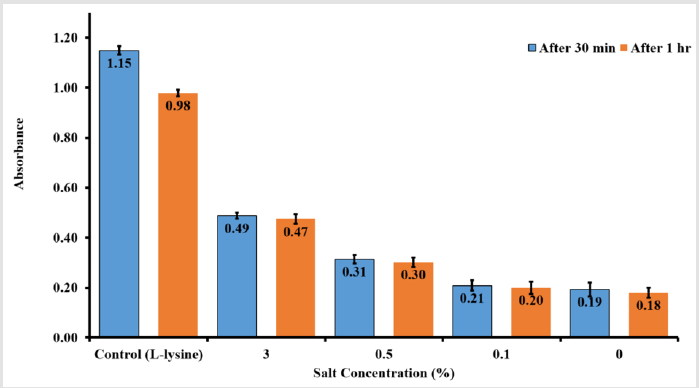

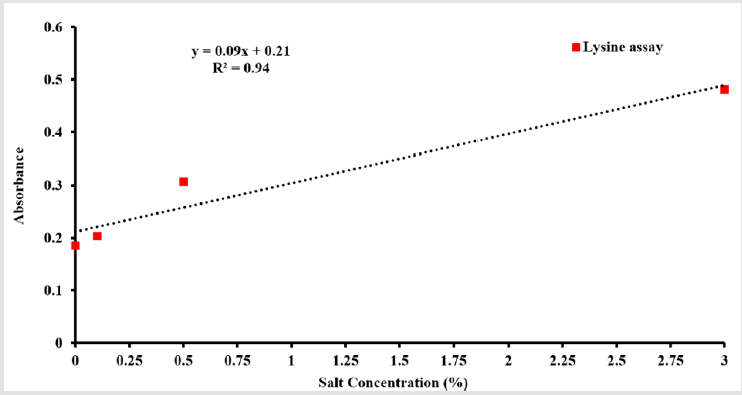

Lysine Assay

The micro BCA assay kit has been used for colorimetric detection and quantitation of total Lysine molecules have attached to nanoporous PLGA microparticles surfaces. The absorbance of the sample at 562 nm was measured on a plate reader (n =3), with a control sample of Lysine in PBS only (Figure 5). The data has been collected after 30 min and after one hour from Lysine addition to nanoporous PLGA microparticles. The assay results showed a correlation between the amounts of Lysine found in each sample with salt concentration used to prepare the sample. A linear response between the salt concentration and the Lysine binding to nanoporous PLGA microparticles surface with a reported R2 = 0.94 (Figure 6).

Discussion

The spherical morphology of the synthesized nanoporous

PLGA microparticle makes the movement more natural due to

their symmetry; therefore, they travel through indirect pathways

with fewer collisions [21]. No direct measurement has been

conducted to calculate the percentage of PLGA microparticles that

became nanoporous because the PLGA microparticles suspended

in the solution undergo Brownian motion. Therefore, the motion

of the particles is entirely random depends on the size, viscosity,

and temperature. Hence, an estimation of the percentage of PLGA

microparticles became nanoporous by reporting the cumulative

distribution percentage from Figure 3 that reflects mean diameters

from each sample. The result shows ~ 50%, 39.8%, and 50.4% of

Sample A, B, and C, respectively, are nanoporous microparticles.

Controlling the nanoporous PLGA microparticles diameter

size in such an approach can be very useful for the microparticles

applications. For example, platelets (size 2 -3 μm) are known to

promote metastasis by protecting cancer cells against natural killer

cells in the blood, because of direct contact between platelets and

targeted cells [22]. The PLGA microparticles size is very close to

platelets; this can be used to assist the physical attachment to the

targeted cell surface.

Table 2 shows the pore size measurement and porosity

percentage calculation for the samples prepared in Table 1 The

analysis shows an increase in porosity (%) as NaHCO3 concentration

increases. Based on the porosity analysis, the process efficiency

to produce nanoporous depends on the salt concentration. On

the other hand, the pore size is random in this case and does not

depend on the salt’s concentration. One-way ANOVA test shows a

p-value of 0.806, which means no significant difference between

the pore sizes from different samples.

The selective targeting approaches require ligands that

specifically interact with receptors expressed on the cell surface.

Therefore, this means multiple copies of the ligand on the PLGA

microparticles surface to increase the binding effects, which results

in higher affinity. The sample with higher porosity showed higher

Lysine concentration, which can be translated into more primary

amines are attached to the surface. The results show an approach

capable of controlling the density of ligand that could conjugate on

the microparticle surface to enhance the binding, which results in

higher affinity. Also, the results showed a stable covalent attachment

of Lysine to nanoporous PLGA microparticles.

Conclusion

This work demonstrates the method to control the porosity

of nanoporous PLGA microparticles. The nanoporous PLGA

microparticles surface was activated with BS3 to form a stable

amide bond with primary amine groups. The double emulation

technique has been used to synthesize the particles. The BS3

crosslinker chemistry has been used to functionalize the

nanoporous PLGA microparticles surface. This work shows stable

amide bond formation between the BS3 and L-lysine and a novel

method to control the amount of Lysine attachment to the surface

by controlling the porosity of PLGA microparticles. The nanoporous

PLGA microparticles platform can be designed to carry out

multifunctional purposes.

Due to the surface area increase, the functionalization of

microparticles can maximize receptor selectively targeting, which

can be recognized as an advanced therapy for cancer. A higher

density of ion channel blockers or any other ligand would be

available for specific binding and reduce non-specific binding.

The PLGA microparticles have been used to load and deliver drug

molecules. The future direction of this platform is to complete

studies with ion channel blockers to develop the cell-targeted

delivery platform.

Acknowledgment

The authors acknowledge experimental assistance and useful discussion with Dr. M. R. Hassan, Dr. Sai S. Sasank Peri, Dr. Nuzhat Mansur, and Dr. M. U. Raza.

Conflicts of Interest

The authors declare no conflict of interest.

References

- ZhengW (2009) A water-in-oil-in-oil-in-water (W/O/O/W) method for producing drug-releasing, doublewalledmicrospheres. Int J Pharm 374(1-2): 90-95.

- BarrowWW (2004) Microsphere technology for chemotherapy of mycobacterial infections. Curr Pharm Des10(26): 3275-3284.

- KapoorDN, Bhatia A, Kaur R, Sharma R, KaurG, et al.(2015) PLGA: a unique polymer for drugdelivery. TherDeliv 6(1): 41-58.

- ShiveMS, Anderson JM (1997) Biodegradation and biocompatibility of PLA and PLGA microspheres. AdvDrugDeliv Rev 28(1): 5-24.

- FredenbergS Wahlgren M,Reslow M,Axelsson A (2011) The mechanisms of drug release in poly lacticco-glycolic acid)-based drug delivery systems--a review. Int J Pharm 415 (1-2): 34-52.

- CegnarM,Kristl J, Kos J (2005) Nanoscale polymer carriers to deliver chemotherapeutic agents to tumours.Expert Opin Biol Ther 5(12): 1557-1569.

- Juillerat-JeanneretL, Schmitt F (2007) Chemical modification of therapeutic drugs or drug vector systemsto achieve targeted therapy: looking for the grail. Med Res Rev27 (4): 574-590.

- HalaszI, Horvath C (1964) Porous Layer Glass Bead Column Packing in Gas Adsorption LayerChromatography. Anal Chem 36(12): 2226.

- HalaszI, Horvath C (1964) Porous Layer Glass Bead Column Packing in Gas Adsorption LayerChromatography. Anal Chem 36(7): 1178-1186.

- KirklandJJ (1976) Porous Silica Microspheres for High-Performance Size Exclusion Chromatography. JChromatogr 125(1): 231-250.

- LaVanDA, McGuire T, Langer R (2003) Small-scale systems for in vivo drug delivery. Nat Biotechnol21(10): 1184-1191.

- Mohamed F van der WalleCF (2008) Engineering biodegradable polyester particles with specific drugtargeting and drug release properties. J Pharm Sci-Us 97(1): 71-87.

- IlyasA, Islam M, Asghar W, Menon JU,Wadajkar AS,et al. (2013) Salt-LeachingSynthesis of Porous PLGA Nanoparticles. Ieee T Nanotechnol 12 (6): 1082-1088.

- KloseD,Siepmann F,Elkharraz K,Krenzlin S,Siepmann J (2006) How porosity and size affect the drugrelease mechanisms from PLIGA-based microparticles. Int J Pharmaceut 314(2): 198-206.

- HutmacherDW (2000) Scaffolds in tissue engineering bone and cartilage. Biomaterials 21(24):2529-2543.

- ChungHJ, Park TG (2007) Surface engineered and drug releasing prefabricated scaffolds for tissueengineering. Adv Drug Deliver Rev 59(4-5): 249-262.

- AbdallahMG,Yousufuddin M,Yaman S, KhanR, Kim Y, et al. (2017) Surface functionalization ofnanoporous PLGA microparticles. 2017 IEEE 12th Nanotechnology Materials and Devices Conference(NMDC): 204-205

- LeeSB, KimYH, ChongMS, Hong SH, Lee YM (2005) Study of gelatin-containing artificial skin V:fabrication of gelatin scaffolds using a salt-leaching method. Biomaterials 26(14): 1961-1968.

- KimTG, Chung HJ, Park TG (2008) Macroporous and nanofibrous hyaluronic acid/collagen hybridscaffold fabricated by concurrent electrospinning and deposition/leaching of salt particles. ActaBiomater 4(6): 1611-1619.

- KarpF,Busatto C,TurinoL, LunaJ,Estenoz D(2019) PLGA nano- and microparticles for the controlledrelease of florfenicol: Experimental and theoretical study. J Appl Polym Sci 136: (12).

- AlmeriaB, Deng WW, Fahmy TM, Gomez A (2010) Controlling the morphology of electrospraygenerated PLGA microparticles for drug delivery. J Colloid Interf Sci 343 (1): 125-133.

- KocbekP, ObermajerN, CegnarM, Kos J, Kristl J(2007) Targeting cancer cells using PLGA nanoparticlessurface modified with monoclonal antibody. J Control Release 120(1-2): 18-26.

Research Article

Research Article