Abstract

Polysaccharides are natural polymers extracted from different sources, with excellent yields, and promising biotechnological applications, especially in the food, biomedical, pharmaceutical, and cosmetic fields. In Brazil, the main researches involving polysaccharides are directly linked to the enormous biodiversity of the country and to the potential industrial application of these polymers. This work aimed to extract the polysaccharide from the seeds of Manjerioba (called Polimanji) and produce films from the filmogenic solution. After the process extraction by ethanol precipitation, the extraction yield (%) and the total carbohydrate concentration were calculated; in addition, the polysaccharide was characterized by FT-IR and the solution was dried under controlled conditions in order to produce the polysaccharide-based film. FT-IR confirmed the polysaccharide nature of Polimanji, which was extracted with 19 % yield, had a total carbohydrate concentration of 3.25 ± 0.17 mg/mL, and resulted in an opaque and hygroscopic film. The obtained results indicate that Polimanji presents inherent properties suitable for the formulation of polysaccharide-based films for biomedical and food applications.

Abbreviations: Mi: Initial Seed Mass; Mf: Final Polysaccharide Mass; FT-IR: Fourier Transform Infrared; ATR: Attenuated Total Reflectance

Short Communication

Polysaccharides are complex polymers containing long chains of monosaccharide units linked by glycosidic bonds [1]. They are naturally extracted from plants, algae, animals, fungi, and microbial fermentation, with excellent yields´ extraction and promisor biotechnological applications, including on food, biomedical, pharmaceutics, and cosmetic fields. Polysaccharides are considered neutral, anionic or cationic depending on their electric charge; in addition, the conformation of the main chain of different polysaccharides is markedly dependent on the ionic strength, the pH, and the temperature of the medium, and the concentration of additional molecules [2]. Polysaccharides are classified as gums or mucilages, both of them derived from natural sources and considered biocompatible, biodegradable, bioavailable, and low- or non-toxic. Besides their similarities, they have particular differences: gums readily dissolve in water, while mucilages form viscous masses; gums are considered pathological products, whereas mucilages are physiological products [3].

The preference of polysaccharides when compared to synthetic materials is closely related to the above-mentioned biological properties, in addition to chemical properties such as polyfunctionality, high chemical reactivity, chirality, chelation, and adsorption capacities [4]. The considerably growing interest in the use of natural polymers occurs due to their diverse structural properties and metabolic functions applicable to different industry products. However, the consumer market still searches for new sources that reach the demand required by the industry [5]; thus, polysaccharides extracted from natural sources can be suggested as the new generation of products from sustainable materials that can combine both ecological and economic aspects. Starch, cellulose, chitin, agar, alginate, pectin, and galactomannan are the main polysaccharides reported in the scientific literature, presenting excellent results as dietary fibers [6,7], texture modifiers, stabilizers and/or emulsifiers [8-10], gelling agents [11,12], thickeners [13,14], food coating [15-17], films/gels for wound healing [18-20], and cosmetics [21,22].

In view of these results, their use was suggested safe in food additives and medications. In Brazil, the main researches involving polysaccharides are directly linked to the enormous biodiversity of our country and the potential industrial application of these polymers. This work aimed to extract the polysaccharide contained in the seeds of Manjerioba, the popular name of Cassia occidentalis, a shrub belonging to the Leguminosae family, subfamily Caesalpiniaceae, commonly found in the northeast region of Brazil. After extraction, the process yield, and the content of total carbohydrates were calculated. Finally, the polysaccharide solution was dried under controlled conditions in order to produce a polysaccharide-based film.

Materials and Methods

Polysaccharide Extraction and Calculation of the Extraction Yield

Cassia occidentalis seeds were collected in the city of Jucati, in the region called Agreste of the Pernambuco state, and processed according to the methodology of Albuquerque et al. [23] with some modifications. The seeds were crushed in an industrial mill, precipitated in 0.1 M NaCl at 5% (w/v), and homogenized in a blender (Power Black 500W - Mondial, Brazil). The resulting solution was filtered through filter paper (Brigitta, Brazil), and the obtained supernatant was precipitated with ethanol 46% (1: 3, w/v) for 18h. Then, the precipitate was washed with acetone PA (1: 1, w/v) twice for 30 min, submitting the precipitate to filtering with filter paper between each wash. The precipitate was dried at room temperature, ground with a pestle, and finally called Polimanji. The extraction yield was calculated by dividing the final polysaccharide mass (Mf) by the initial seed mass (Mi) and expressed as %.

Determination of the Total Carbohydrate Concentration

The concentration of total carbohydrates was carried out according to the methodology described by Dubois et al. [24].

Production of the Polysaccharide-Based Film

The filmogenic solution of Polimanji was prepared in distilled water with 0.5 % (w/v) concentration and keep under magnetic stirring (250 rpm) for 18 h, at room temperature (20 ± 2 0C). 15 mL of the filmogenic solution was distributed in a 90 mm diameter polystyrene Petri dish. The film was dried in an oven at 55.7 0C for 9 h and stored in a dry environment.

Fourier-Transform Infrared (FT-IR) Spectroscopy

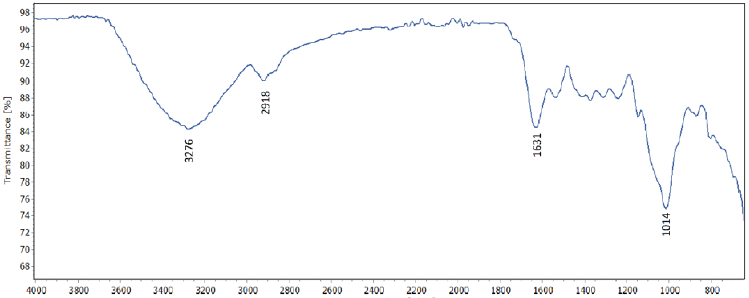

Polimanji was characterized by Fourier Transform Infrared (FT-IR) Spectroscopy on a Bruker FT-IR VERTEX 80/80 v (Boston, USA) in Attenuated Total Reflectance mode (ATR) with a platinum crystal accessory between 400 and 4000 cm-1, using 16 scans at a resolution of 4 cm-1. Data analysis was performed with GraphPad Prism 5.00.288 (GraphPad Software, Inc., San Diego, CA, USA).

Results

The extraction yield of Polimanji was calculated and expressed as a percentage of dry mass obtained after extraction in relation to the dry weight of the seeds, resulting in a value of 19%. The result of the chemical analysis for the content of total carbohydrates was determined to be 3.25 ± 0.17 mg/mL. The presence of carbohydrates in the seeds of Manjerioba allowed the production of a filmogenic solution at 0.5 % (w/v), which was dried, and resulted in a film with viscosity and opacity commonly found in Legumes seeds (Figure 1). The FT-IR spectra (Figure 2) showed typical absorption peaks of polysaccharides at around 3276, 2918, and 1014 cm-1 [25], which could be attributed to the stretching vibration of the O-H, C-H, and C-O bonds, respectively. The peak at approximately 1631 cm-1 is in the region correspondent to asymmetric stretching of the carboxylate anions (COO-) [26,27] (Figure 2).

Figure 1: Polysaccharide-based film formulated with the filmogenic solution of Polimanji at 0.5% (w/v).

Discussion

The endosperm of Legumes seeds contains carbohydrates responsible for the functions of hydration and energy reserve [28]. The yield of 19 % for the Polimanji extraction process is similar to the values of 20,49 % [29] and 17,95 % [30] for the Basil seed gum, and lower than the result obtained by Albuquerque et al. (2014) [23], whose yield for the extraction of the galactomannan from the seeds of Cassia grandis was 36 % ± 8. Regarding the extraction yield for the polysaccharides of the subfamily Caesalpinioideae, several studies reported values between 8 and 40 % of the seed weight, which are higher than the values for other species of Brazilian legumes [31]. The Polimanji solution presented a total carbohydrate concentration of 3.25 ± 0.17 mg/mL, similar than the results obtained for Vercelollotti et al., (1995) in postharvest fruits (6.78 ± 0.32, 5.74 ± 0.52, 4.26 ± 0.08, and 3.56 ± 0.60).

Other works presented values of total carbohydrate contents in percentage [32] and mg/g [33]; in general, the concentration of total carbohydrates can be influenced by different factors, such as extraction method, temperature, metabolism, and biosynthesis of different sugars, inferring about the storage capacity of sugars and, therefore, justifying the different values reported by the scientific literature. FT-IR is a valuable technique for studying polymers, estimating chemical interactions and possible modifications in their structure [34]. The FT-IR spectra for Polimanji shows typical bands and signals for a polysaccharide, confirming what is expected for the extraction of polymers from Legume seeds. In addition, the intrinsic properties of Polimanji and the ability to form a viscous filmogenic solution allows the use of the polysaccharide in different biotechnological applications, such as films for food and biomedical areas.

Conclusion

The production of polysaccharide-based films for food and biomedical areas have been extensively studied worldwide; however, new sources of carbohydrates are gaining special attention due to the recent concern to use natural products to formulate new products for the industry. The results obtained in this work contribute to the scientific and technical development of polysaccharide-based films from a Brazilian regional plant, meantime further studies are needed to better describe its biotechnological activities and applications.

Acknowledgment

Authors acknowledge the National Council for Scientific and Technological Development - CNPQ for the finantial support of the project n0 29014 / 2019-2.

References

- Gopinath V, Saravanan S, Al Maleki AR, Ramesh M, Vadivelu J (2018) A review of natural polysaccharides for drug delivery applications: Special focus on cellulose, starch and glycogen. Biomed Pharmacother 107: 96-108.

- Prajapati VD, Maheriya PM, Jani GK, Solanki HK (2014) Carrageenan: A natural seaweed polysaccharide and its applications. Carbohydr Polym 105(1): 97-112.

- Albuquerque LCBB, Coelho JA, Teixeira (2017) Approaches in biotechnological applications of natural polymers. AIMS Mol Sci 3(3): 386-425.

- M Hossain, IH Mondal (2014) Biodegradable Surfactant from Natural Starch for the Reduction of Environmental Pollution and Safety for Water Living Organism. Int J Innov Res Adv Eng 1(8): 424-433.

- Albuquerque PBS, Malafaia CB (2017) Perspectives on the production, structural characteristics and potential applications of bioplastics derived from polyhydroxyalkanoates. Int J Biol 107(Pt A): 615-625.

- W Zhang, G Zheng, Y Pan, W Chen, W Huang, et al. (2017) Properties of Soluble Dietary Fiber-Polysaccharide from Papaya Peel Obtained Through Alkaline or Ultrasound-Assisted Alkaline Extraction. Carbohydr Polym 172: 102-112.

- Nawrocka, M Szymanska Chargot, A Mis, AZ Wilczewska, KH Markiewicz (2017) Effect of dietary fibre polysaccharides on structure and thermal properties of gluten proteins - A study on gluten dough with application of FT-Raman spectroscopy, TGA and DSC. Food Hydrocoll 69: 410-421.

- Z Hao, X Peng, C Tang (2020) Edible Pickering High Internal Phase Emulsions Stabilized by Soy Glycinin: Improvement of Emulsification Performance and Pickering Stabilization by Glycation with Soy Polysaccharide,” Food Hydrocoll 103: 105672.

- K Xu, M Guo, J Du, Z Zhang (2019) Okra polysaccharide: Effect on the texture and microstructure of set yoghurt as a new natural stabilizer. Int J Biol Macromol 133: 117-126.

- SH Hosseini Parvar, JP Osano, L Matia Merino (2016) Food Hydrocolloids Emulsifying properties of basil seed gum : Effect of pH and ionic strength. Food Hydrocoll 52: 838-847.

- S Wang, G Shao, J Yang, H Zhao, L Ying, et al. (2019) The production of gel beads of soybean hull polysaccharides loaded with soy isoflavone and their pH-dependent release. Food Chemistry 313: 126095.

- Z Pang, H Deeth, S Prakash, N Bansal (2016) Development of rheological and sensory properties of combinations of milk proteins and gelling polysaccharides as potential gelatin replacements in the manufacture of stirred acid milk gels and yogurt. J Food Eng 168: 27-37.

- Cho HM, Yoo B (2015) Rheological characteristics of cold thickened beverages containing xanthan gum-based food thickeners used for dysphagia diets. J Acad Nutr Diet 115(1): 106-111.

- L de S Soares, GL Milião, B Tonole, GB de Souza, N de Fátima Ferreira Soares, et al. (2019) Chitosan dispersed in aqueous solutions of acetic, glycolic, propionic or lactic acid as a thickener/stabilizer agent of O/W emulsions produced by ultrasonic homogenization. Ultrasonics Sonochemistry 59: 104754.

- P Cazón, G Velazquez, JA Ramírez, M Vázquez (2017) Polysaccharide-based fi lms and coatings for food packaging : A review. Food Hydrocolloids 68: 136-148.

- MA Moreno, H Bojorges, I Falco, G Sanchez, G Lopez Carballo, et al. (2019) Active properties of edible marine polysaccharide-based coatings containing Larrea nitida polyphenols enriched extract. Food Hydrocoll 102: 105595.

- F Bouaziz, M Koubaa, M Neifar, SZ Ellouzi, S Besbes, et al. (2016) Feasibility of using almond gum as coating agent to improve the quality of fried potato chips: Evaluation of sensorial properties. LWT - Food Sci Technol 65: 800-807.

- Albuquerque PBS, Soares PAG, Aragão Neto AC, Albuquerque GS, Silva LCN, et al. (2017) Healing activity evaluation of the galactomannan film obtained from Cassia grandis seeds with immobilized C ratylia mollis seed lectin. Int J Biol Macromol 102: 749-757.

- Zhou J, Yao D, Qian Z, Hou S, Li L, et al. (2018) Bacteria-responsive intelligent wound dressing: Simultaneous In situ detection and inhibition of bacterial infection for accelerated wound healing. Biomaterials 161: 11-23.

- D Ribeiro, AR Carvalho, GHR Vale De Macedo, VL Chagas, L Dos Santos Silva, et al. (2020) Polysaccharide-Based Formulations for Healing of Skin-Related Wound Infections: Lessons from Animal Models and Clinical Trials. Biomolecules 10(1): 63-79.

- Gabriel AB Damasceno, Stella MAG Barreto, Fernanda PS Reginaldo, Augusto L Souto, Marília MF Negreiros, et al. (2020) Prosopis juliflora as a new cosmetic ingredient: development and clinical evaluation of a bioactive moisturizing and anti-aging innovative solid core. Carbohydr Polym 233.

- Jesumani V, Du H, Pei P, Zheng C, Cheong KL, et al. (2019) Unravelling property of polysaccharides from Sargassum sp . as an anti- wrinkle and skin whitening property. Int J Biol Macromol 140: 216-224.

- Albuquerque PB, Barros W, Santos GR, Correia MT, Mourão PA, et al. (2014) Characterization and rheological study of the galactomannan extracted from seeds of Cassia grandis. Carbohydr Polym 104: 127-134.

- M Dubois, KA Gilles, JK Hamilton, PA Rebers, F Smith (1956) Colorimetric Method for Determination of Sugars and Related Substances. Anal Chem 28(3): 350-356.

- SN Yuen, SM Choi, DL Phillips, CY Ma (2009) Raman and FTIR spectroscopic study of carboxymethylated non-starch polysaccharides. Food Chem 114(3): 1091-1098.

- P Zhao, Y Wang, L Yan, L Guo, L Huang, et al. (2020) Characterisation and saccharide mapping of polysaccharides from four common Polygonatum spp. Carbohydr Polym 233: 115836.

- Y Chen, JG Zhang, HJ Sun, ZJ Wei (2014) Pectin from Abelmoschus esculentus: Optimization of extraction and rheological properties. Int J Biol Macromol 70: 498-505.

- PBS Albuquerque, LCBB Coelho, MTS Correia, JA Teixeira, MG Carneiro da Cunha (2016) Biotechnological Applications of Galactomannan Matrices: Emphasis on Immobilization of Biomolecules. Adv Res 6(5): 1-17.

- SMA Razavi, S Naji Tabasi (2017) Rheology and Texture of Basil Seed Gum: A New Hydrocolloid Source. Advances in Food Rheology and its Applications pp. 405-435.

- F Salehi, M Kashaninejad, A Tadayyon, F Arabameri (2014) Modeling of extraction process of crude polysaccharides from Basil seeds (Ocimum basilicum l .) as affected by process variables,” J. Food Sci. Technol 52(8): 5220-5227.

- MS Buckeridge, VR Panegassi, DC Rocha, SMC Dietrich (1995) Seed galactomannan in the classification and evolution of the Leguminosae. Phytochemistry 38(4): 871-875.

- Samal PK, Dangi JS (2014) Isolation, preliminary characterization and hepatoprotective activity of polysaccharides from Tamarindus indica L. Carbohydr Polym 102: 1-7.

- F El Amerany, M Rhazi, S Wahbi, M Taourirte, A Meddich (2020) The effect of chitosan, arbuscular mycorrhizal fungi, and compost applied individually or in combination on growth, nutrient uptake, and stem anatomy of tomato. Scientia Horticulturae 261: 109015.

- PBS de Albuquerque, KS de Araújo, KAA da Silva, LM Houllou, GO Locatelli, et al. (2018) Potential production of bioplastics polyhydroxyalkanoates using residual glycerol. J Environ Anal Prog 3(1): 55-60.

Short Communication

Short Communication