Short Communication

The titanium has been a part of the group of materials used in

areas where excellent corrosion resistance and high strength are

required. Due to its outstanding properties it is used in medicine,

mainly thanks to biocompatibility and corrosion resistance in the

environment of body fluids. It is used to make implants, stents and

prostheses. Nevertheless, the titanium main disadvantage, apart

from high manufacturing costs, is its relatively low wear resistance.

The Titanium Metal Matrix Composites (TMMCs) are increasingly

used to eliminate this disadvantage. Hard ceramic reinforcement

phases in the form of fiber or powders, e.g. SiC, TiC, Al2O3, TiB2,

are often added to the metallic titanium matrix for this purpose [1-

7]. The preliminary studies of titanium composites reinforced with

nanocrystalline powders from (Ti,Mo)C/C system are presented by

this paper.

The powders were sintered using an SPS-type furnace

(U-FAST, GeniCore, Poland). Recent years have showed significant

developments in the methods of sintering by activated electric field.

These methods allow to perform the sintering process in a very

short period of time from a few to several minutes, thus reducing

the unfavorable grain growth in the consolidated material. In

these techniques the sintering process is performed at a uniaxial

pressure. U-FAST (Upgraded Field Assisted Sintering Technology)

having a characteristic method of powder heating. The innovative

solutions open the perspective for sintering of the new materials

and has unique characteristics. Pulse power modular supplies

offer the shortest impulse duration, less than 1ms. Together with

the higher power supply voltage (14 V), they make this technology

effective, energy-saving and dedicated to the consolidation of

nanocrystalline materials [8,9].

Experimental

As starting matrix material, the one type of cp-Ti powder (grade 1), with a spherical shape and its average particle size around 100μm from SLM Solutions GmbH, was employed. As a reinforcements two type of nanoparticles were used: (Ti,Mo)C with an average crystallite size of 25nm and (Ti,Mo)C/C carbides embedded in carbon network with an average crystallite size of 12nm and ca 40wt.% elemental carbon. Before the sintering titanium with reinforcing carbides phase was milled during 12h, in order to obtain a uniform mixing of powders. Sintering processes were conducted in high vacuum (10-5mbar). Powder mixtures were placed into cylindrical graphite die with inner diameter of 20mm. The pulse sequence was set to 1:1 (tON:tOFF). The temperature was monitored by an axial and a side optical pyrometer. Samples were heated to the desired temperatures with the ramp of 400°C/ min. Sintering temperature was 1050°C and 1150°C with 2min and 24min of dwell time, respectively. In all cases, the U-FAST was performer under uniaxial mechanical pressure of 50 MPa, applied during the whole sintering process, including heating ramps and cooling. The density was determined by hydrostatic method after ultrasonic cleaning and vacuum drying. The microhardness was measured by Vickers method under load 100g. Potentiodynamic polarization measurements were carried out on the Atlas-Sollich 9833 potentiostat in a three-electrode system. The parameters of the test were as follows: a scan rate of 0.01V/s at a potential initiated at -1.2V to +2.0V. The calomel (reference) and graphite (auxiliary) electrodes were used. The analysis of the results has been carried out by means of the AtlasLab software. Pure titanium (cp-Ti) and Ti-6Al-4V alloy were used as reference samples.

Results

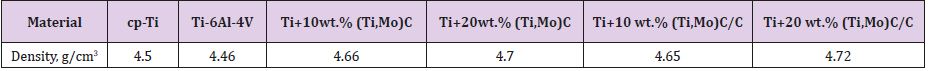

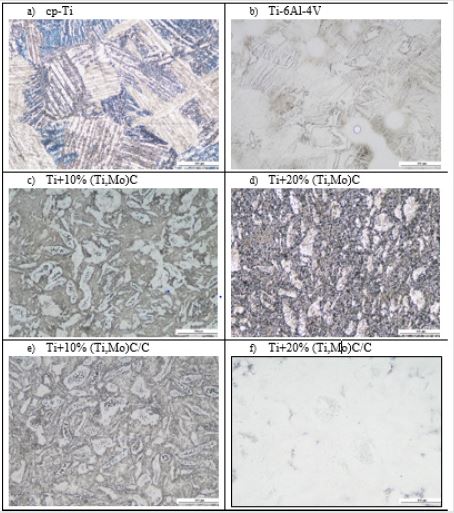

The sintering processes of titanium materials with the addition of titanium strengthening phases (Ti,Mo)C and (Ti,Mo)C/C were carried out. The materials were sintered at 1050oC, which allowed to obtain a density of samples corresponding to theoretical values. In the case of addition 20% (Ti,Mo)C/C the minimum temperature to achieve total compaction was 1150oC with dwell time 24min. The density after sintering at 1050oC was 3.86g/cm3, thus not been studied. The obtained values are summarized in (Tables 1 & 2). Vickers hardness measurements made at different locations on the surface of each samples are summarized in (Figure 1). The samples were polished to a mirror finish before the hardness measurement. The measured hardness was observed to be near uniform throughout each sintered sample, indicating uniform densification.

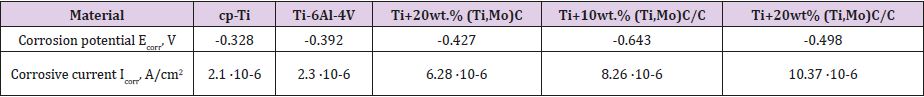

Based on images from an Optical Microscope (OM), the microstructure of the tested materials was determined. Pictures are shown in (Figure 2). In the case of pure titanium, a typical needle (dendritic) structure is visible (Figure 2a). For the Ti-6Al-4V alloy (Figure 2b), the bi-modal microstructure of titanium α and β is observe. The lighter fields are the α phase, while the darker fields are the Widmanstätten phase. Figures 2 c-f show the microstructure of composites with a strengthening phase. The greater addition of this phase has a positive effect on the homogeneity of the material, which is confirmed by measurements of both density and hardness. Smaller amounts of matrix are visible in the case of (Ti,Mo)C/C type of carbides, due to the reaction of free carbon with the titanium matrix. This is especially visible in the case of 20% (Ti,Mo)C/C.

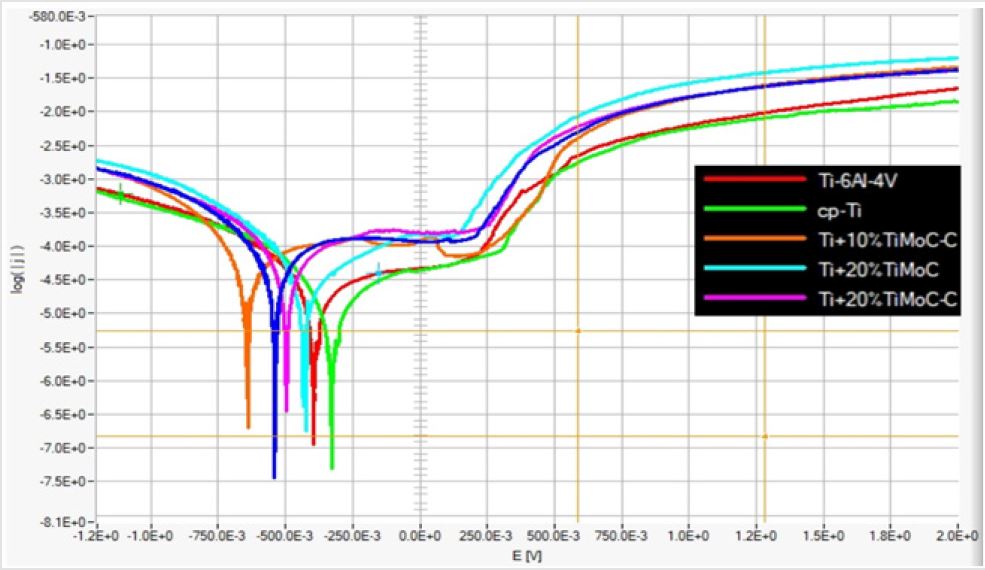

For selected materials tested corrosion. Polarizing curves for titanium and titanium composites are shown in (Figure 3). Corrosion tests were carried out in Ringer’s solution, an electrolyte with a composition similar to extracellular fluid, simulating body fluids. Corrosion parameters of sintered materials are shown in (Table 2) In case of pure Ti sample immersed in artificial saliva solution, corrosion potential was at the level of -0.328 V and corrosion current density reached 2.1·10-6 A∙cm-2, and in the case of Ti-6Al-4V alloy corrosion potential was at the level of -0.392V and corrosion current density reached 2.3∙10-6 A∙cm-2 Corrosion results shows that the composites generally displayed similar polarization curves and passivity characteristics. However, the corrosion potentials (Ecorr) of the composites were clearly distinct and occurred in the ranges of -0.498 to -0.643V. Analysis of the results of corrosion tests showed that the corrosion potential (Ecorr) and the density of corrosive current (Icorr) of composites show a constant tendency to change the value with the increase of the mass fraction of the reinforcement phase. When titanium composites were immersed in Ringer’s solution, the corrosion potential generally shifts to lower values towards cathodic region. Also, corrosion current increased with increasing reinforcing phase content.

Summary

Powder contaminations are an obstacle to mass transport processes during the sintering. U-FAST technology allows better control over diffusion processes. Spark discharges generated during sintering remove adsorbed gases and oxides from the surface of particles, facilitating the formation of active contacts between sintered powder particles. This affects the lower sintering temperature and a shorter heating time. This work has already produced perfectly concentrated (100% of theoretical density) titanium material, a popular alloy as well as titanium composite materials at 1050oC by 2min. Together with the applied load, it results in rearrangement of powder particles and obtaining a homogeneous sintered microstructure. The use of 20 wt.% (Ti,Mo)C additive in U-FAST sintering technology allowed to obtain materials with the HV hardness 1203±108, even up to 600% compared to pure titanium. In the case of 20wt.% of the (Ti,Mo)C/C additive, the material has a hardness of 1581±138HV, which is over 800% higher than hardness of the pure titanium. Corrosion properties of titanium composites similar to reference cp-Ti and Ti-6Al-4V were obtained. The article shows that U-FAST technology is useful for the production of titanium-based biomaterials. Further optimization of the powders preparation and sintering processes will contribute to the manufacturing materials with even more favorable parameters.

References

- Poletti C, Balog M, Schubert T, Liedtke V, Edtmaier C (2008) Laser Additive Manufacturing of High-Performance Materials. Compos Sci Technol 68(9): 2171-2177.

- Alman DE, Hawk JA (1999) The abrasive wear of sintered titanium matrix–ceramic particle reinforced composites. Wear 1: 629-639.

- Gülsoy HO, Gunay V, Baykara T (2015) Influence of TiC, TiN and TiC(N) additions on sintering and mechanical properties of injection moulded titanium based metal matrix composites. Powder Metall 58(1): 30-35.

- Da Silva AM, Meyer A, Dos Santos JF, Kwietniewski CEF, Strohaecker TR (2004) Compos Sci Technol 64: 1495-1501.

- Gu D, Hagedorn YC, Meiners W, Wissenbach K, Poprawe R (2011) Selective Laser Melting Additive Manufacturing of TiC/AlSi10Mg Bulk-form Nanocomposites with Tailored Microstructures and Properties. Compos Sci Technol 71: 1612-1620.

- Figiel P, Garbiec D, Biedunkiewicz A, Biedunkiewicz W, Kochmański P, et al. (2018) Microstructural, Corrosion And Abrasive Characteristics Of Titanium Matrix Composites. Arch Metall Mater 63 (4): 2051-2059.

- Wang Z, Zhang H, Guo C, Liu W, Yang Z (2016) Mater Sci 51(10): 4996-5007.

- Jach K, Rosiński M (2018) Ceramic Materials 70: 293-300.

- Ppc sintering machines.

Short Communication

Short Communication