Abstract

Nanocomposite Ti 50 wt% Nb with and without reinforcement of carbon nanotubes were successfully fabricated by ball milling of Ti, Nb and SWCNTs nano powder mixture followed by field activated spark plasma sintering process (FASPS) for biomedical application, superconductivity and magnetism in the ITER Project. The use of brittle Ti powder, instead of ductile elemental powder, led to significant increment in the yield of mechanically alloyed powder. The powder consisted of homogeneously distributed nano-sized Ti/Nb particles together with micron-sized pure Nb particles. Sintering of the powders under low temperature and pressure conditions (1273 K, 1473 K and P=50 MPA) resulted in the fine-grained heterogeneous microstructure consisting of α and β phases. On the other hand, sintering at higher temperatures (1473 K) resulted in a relatively coarsegrained chemically homogeneous microstructure with almost complete phase.

Coarse-grained homogeneous β TiNb alloy exhibited higher average hardness as compared to that of heterogeneous fine-grained microstructures. An attempt has been made to illustrate the correlation between the microstructural characteristics and mechanical properties of the sintered Ti50Nb compacts. To studies and to develop the influence of CNTs on the behavior of the nanocomposite TiNb/CNTs and the welding joint interface between TA6V and nanocomposite by Sparck plasma sintering. At last, the continuation of the work has been discussed and prepared, planning dynamic flexion tests to measure the TiNb, TiNb/CNTs, TiNb/CNTs,/TA6V fatigue limit and developing a computer processing chain in order to customize prostheses respecting patients’ morphology. The fluid enhanced lubrification of the prosthesis articulation is currently also in preparation.

Keywords: Titanium alloys; Ti50Nb; CNTs; Stress-shielding Nano-indentation; Wear; Friction coefficient; Galvanic corrosion; Biomechanics; Biomedical; Superconductivity

Introduction

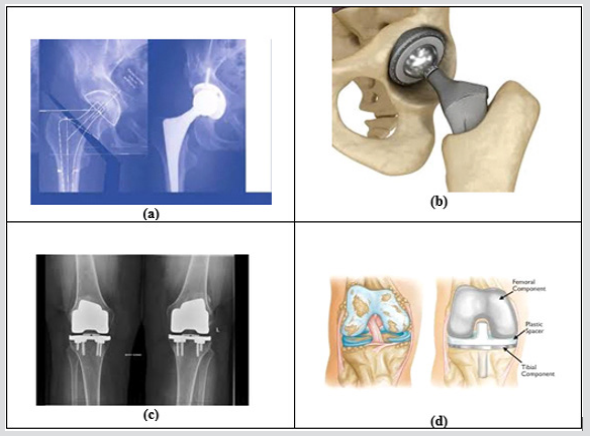

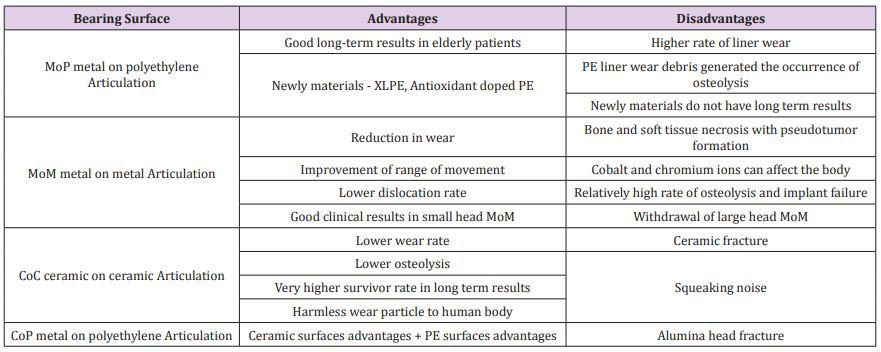

Total hip arthroplasty (THA) and Total knee arthroplasty (TKA) (Figure 1) has been a successful, increasing practice for caring for hip arthritis in the aging and active population by novel biomaterials (Table 1). The advent of new techniques and efficiency has advanced the practice to one of the more reproducible and beneficial operations orthopedic surgeons perform. Because of the increasing age of the American population, the need and number of hip replacements performed is expected to increase over the coming decades. With that in mind, surgeons have been advancing the practice of joint replacement in both the knee and the hip to accommodate the active lifestyles and demands of patients [1,2]. More and more patients desire to be home in a timely manner and get back to work and daily activities as soon as they can tolerate. Several studies have shown the benefits and successful outcomes of an outpatient approach to joint replacement surgery [3,4].

One surgeon’s experience with transitioning to outpatient total hip arthroplasty and the development of a successful outpatient program (Figure 1). The bearing surfaces of the novel biomaterials used in THA and THK is presented in (Table 1). Over the past two and a half years, the technique has evolved, and patients were followed to determine whether this idea was plausible. The thought being that patients who are healthy enough and motivated to go home after surgery might recover just as well as those who had traditionally stayed in a hospital for two-sometimes three-days. The practice has instituted an outpatient hip replacement model that has been used successfully in both the hospital and ambulatory surgery center settings. Total Hip Arthroplasty (THA) is used to replace a damaged hip joint. Bone is a living tissue which remodel itself depending on its solicitations. If a bone does not withstand enough stresses, it will lose density be weakened and fracture. After a joint replacement, the differences of mechanical properties, and mostly the Young’s modulus, between the prosthesis (110 GPA) and the bone (20 GPA) modifies the solicitations distribution. This phenomenon is called stress-shielding because it obstructs the constraints transmission from the implant to the bone.

Figure 1: Novel biomaterials used in Total hip arthroplasty (THA) and Total knee arthroplasty (TKA).

Table 1: Advantages and disadvantages of bearing surfaces of the novel biomaterials used in THA and THK.

However, coating the prosthetic stem, by the process, with a super elastic titanium alloy, TiNb, might reduce the stressshielding effect. This TiNb alloy [5,6] has a low Young’s modulus (60 to 80 GPA) which can be lowered (about 35 GPA) thanks to a “flash sintering” The stresses distribution should be enhanced, the bone more stimulated resulting in a lower risk of fracture or implant loosening. The ultimate aim of this work is to demonstrate the biomaterials TiNb alloys, TiNb/CNTs [3] nanocomposites and TiNb/CNTs/TA6V after welding by FASPS has the required mechanical and chemical properties for this kind of biomedical applications. First, nanoindentation tests were performed with a coupled analysis in a scanning electron microscope to show the gradient properties the interface between the bulk TA6V [7-9] and the TiNb, TiNb/CNTs, bulk biomaterials. Scratch and wear tests were used to study the tribological properties of this titanium alloy nanocomposite in comparison with welded with TA6V. Then, galvanic corrosion risk was also analyzed between the interface of TA6V and TiNb and TiNb/CNTs in physiological medium.

At last, the continuation of the work has been discussed and prepared, planning dynamic flexion tests to measure the TiNb, TiNb/CNTs and TiNb/CNTs/TA6V fatigue limit and developing a computer processing chain in order to customize prostheses respecting patients’ morphology. Titanium and its alloys have been widely used in key engineering applications covering a variety of areas, such as aerospace, marine, biomaterials, chemical industries, sports, etc., due to their unique combination of outstanding mechanical and chemical properties. In spite of all the meritorious properties of titanium-based alloys and reinforced by CNTs, the complexities associated with their thermo-mechanical processing and subsequent machining limit their widespread usage. Therefore, it is necessary to develop an optimum fabrication/processing strategy to offer commercially viable and good quality Ti-based near-net shaped products.

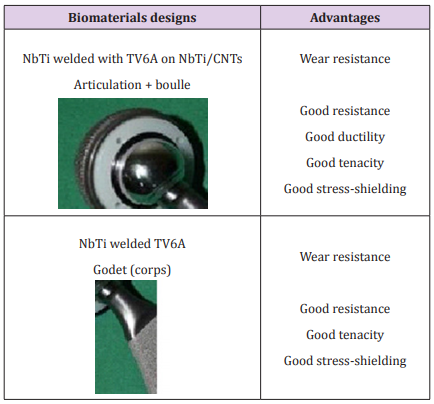

A field activated sparks plasma sintering process (FASPS). Based on the processing approach could be a suitable way of achieving good relative density and mechanical properties. However, the preparation and handling of Ti-based powders has several issues associated with it. The suggested novel biomaterials proposed for THA and THK is illustrated in the Table 2. Nevertheless, in recent years, several new processes have been developed to prepare high quality elemental Ti and Ti-alloys at a relatively lower cost [10]. These processes combined with other secondary powder metallurgy-based operations in situ spark plasma sinter design and manufacturing of prosthesis offer several advantages over other conventional fabrication processes, enhancing the feasibility of commercial viability of titanium, its alloys and nanocomposites.

Conclusion

THA remains a highly successful procedure providing good pain relief and improvement of activity levels. Despite its success, the expectations continue to increase with more and more young patients undergoing hip replacement and most of them seeking higher activity level (higher range of motion and stability in those ranges) as well as longevity of the prosthesis. Besides, the fixation method for the prosthesis, good surgical approach, bearing surfaces remains the most important determinant of longevity of the hip prosthesis. Newer bearing surfaces in current clinical practice have shown promising clinical outcomes. With success of these wear reducing bearing surfaces, the scientific community will need to focus on not only further reducing abrasive wear but on reducing stress shielding as well by newer biomaterials as well as designs. Ongoing research and the future of biomaterials in the hip are anticipated. The effect carbon nanotubes additions and sintering temperature on the microstructure and mechanical properties of the sintered binary Nb 50 wt.

Ti% alloy compacts have been evaluated, and the results related to this aspect are presented and discussed. The possibility to develop the weldability of NbTi/CNTs nanocomposites [3] with TA6V alloys to form NbTi/CNTs/TA6V by in situ spark plasma sinter design and manufacturing of prosthesis is achieved after a technology of the machining of the spacer, die and matrix of the FCT sintering machine of the more complicate geometry of the Total Hip and Knee Arthroplasty (THA, TKA) prosthesis. The prosthesis ball and joint is made of NbTi and NbTi-CNT because it offers good ductility and reduce strain, stress and bearing surfaces and wear resistance by addicting of the CNT at the hip, the body of the prosthesis is made of TV6A welded with the ball and introduced with the femur one offering him a good tenacity, NbTi/CNTs nanocomposites has required mechanical and chemical properties for this kind of biomedical applications. First, nanoindentation tests were performed with a coupled analysis in a scanning electron microscope to show the gradient properties the interface between the TA6V bulk substrate and the NbTi/CNTs adding.

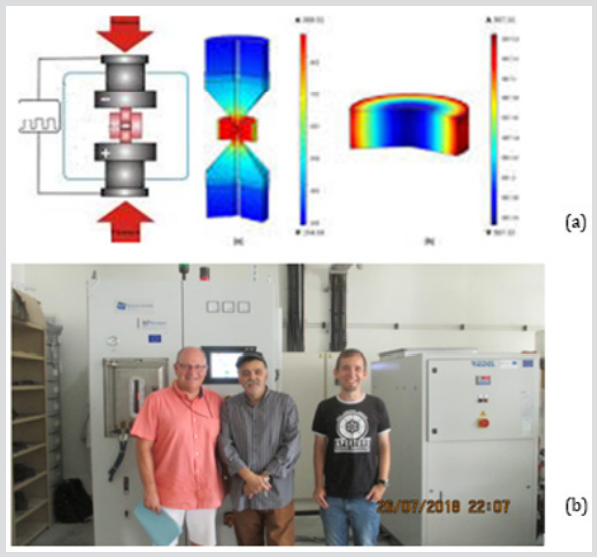

Scratch and wear tests were used to study the tribological properties of this Titanium alloy in comparison with TA6V. Then, galvanic corrosion risk was also analyzed between TA6V/TiNb and NbTi/CNTs in physiological medium. At last, the continuation of the work has been discussed and prepared, planning dynamic flexion tests to measure the NbTi and NbTi/CNTs/TA6V fatigue limit and developing a computer processing chain in order to customize prostheses respecting patients’ morphology. The in-situ spark plasma sintering process for the manufacturing of prosthesis of THA and THK with the detailed parameters. The design and manufacturing of punch, spacer and die for the prosthesis (KHA and TKA), simulation of the thermomechanical properties (temperature, strain-tress) and weldability under Abaqus will be performed in the near future (Figure 2). The fluid lubrification of the prosthesis articulation is currently also in study.

Figure 2: a- Design and manufacturing of punch and die for the prosthesis (KHA and TKA), b- Simulation of the thermomecanical properties and weld ability under Abaqus. c-Sparck plasma sinter machine (FCT Germany) at the Laboratoire Interdisciplinaire Carnot of Bourgogne (ICB), Dijon, France (Photo July 2018).

References

- RA Berger, S Sanders, T Gerlinger, Della Valle C, Jacobs JJ, et al. (2005) Outpatient total knee arthroplasty with a minimally invasive technique. J Arthroplasty 20 (7 Suppl 3): 33-38.

- Berger RA, Sanders SA, Thill ES, Sporer SM, Della Valle C (2009) Newer anesthesia and rehabilitation protocols enable outpatient hip replacement in selected patients. Clin Orthop Relat Res 467(6): 1424-1430.

- Dorr LD, Thomas DJ, Zhu J, Dastane M, Chao L, et al. (2010) Outpatient total hip arthroplasty. J Arthroplasty 25(4): 501-506.

- Goyal N, Chen AF, Padgett SE, Tan TL, Kheir MM, et al. (2017) Otto Aufranc Award: A multicenter, randomized study of outpatient versus inpatient total hip arthroplasty. Clin Orthop Relat Res 475(2): 364-372.

- K Zhuravleva, M Bonisch, S Scudino, M Calin, L Schultz, et al. (2014) Phase transformations in ball milled Ti40Nb and Ti45Nb powders upon quenching from beta phase. Powder Technol 253: 546.

- Zhuravleva K, Bönisch M, Prashanth KG, Hempel U, Helth A, et al. (2013) Production of Porous β-Type Ti40Nb Alloy for Biomedical Applications: Comparison of Selective Laser Melting and Hot-Pressing Materials 6(12): 5700-5712.

- C Zhenhua , Y Guangyin, K Hidemi, X Guoqiang, Y Dianran (2015) The study on interface and property of TiNb/Zr-based metallic glassy composite fabricated by SPS. Journal of Non-Crystalline Solids 426: 83-87.

- P Goudeau, L Vandenbulcke, C Met, M I De Barros, M Gailhanou (2005) X-ray diffraction analysis of residual stresses in smooth fined-grain diamond coatings deposited on TA6V alloys; Surface and Coatings Technology 200(1-4): 170-173.

- Damien Mauduit, Marion Le Fournier, Kevin Grondin, Thomas Pottier, Yannick Le Maoult (2017) Industrial applications of the superplastic forming by using Infra-Red heater, Procedia Engineering 207: 1898-1903.

- FH Froes, M Ashraf Imam, Fray Derek (2004) Cost Affordable Titanium, Warrendale, PA: TMS.

Mini Review

Mini Review