Opinion

A new technical solution for removing a filter unit from a laboratory extraction hood in safety conditions for an operator and for the surrounding environment according to Italian Legislative Decree 81/2008 and subsequent amendments, with particular reference to Titles I and IX, transposition of Directive 89/391/EEC , Directive 2009/104/EC concerning the minimum safety and health requirements for the use of work equipment by workers at work, Directive 2009/148/EC on the protection of workers from the risks related to exposure to asbestos at work, Directive 2004/37/EC on the protection of workers from the risks related to exposure to carcinogens or mutagens at work. Asbestos is a highly dangerous carcinogenic agent: airborne fibres are very resistant when inhaled and can lead to asbestosis, lung cancer or cancer of the pleura. In Europe, asbestos-related diseases lead to thousands of deaths each year and the number of the cases is rising. Safety measures are therefore required in individual cases to prevent the release of fibres and the resulting environmental threats.

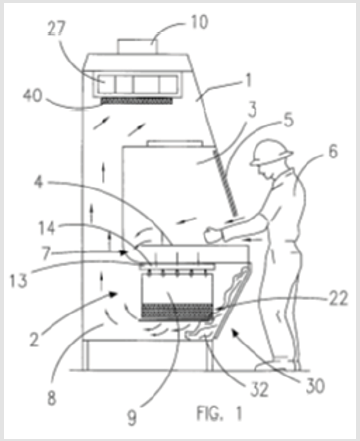

According to Council Directive 89/391/EEC of 12 June 1989, the employer has a duty to ensure the safety and health of workers in every aspect related to the work. Within the context of his responsibilities, the employer has to take the measures necessary for the safety and health protection of workers, on the basis of the following general principles of prevention such as adapting to technical progress and giving collective protective measures priority over individual protective measures. A recent technological innovation is currently available for all laboratories carrying out asbestos sample analysis as well as airborne fibers concentration detection: a chemical hood, specifically designed for managing risks coming from asbestos and other cancerogenic/mutagenic substances, is a new technical solution in compliance with European rules on safety and health of workers (Figure 1).

It is known that laboratory extraction hoods require the filter unit to be replaced periodically: replacing a filter unit is a very delicate operation that requires extreme caution and suitable measures to protect the operator ant the environment from contamination by hazardous substances laying on the filter, such as asbestos fibers.

Individual protective measures (such as gloves, masks etc.) may not be sufficient to meet European requirements: there is thus a great need to improve measures for protecting operators and environment, in particular during critical operations of removing and replacing laboratory extraction hoods filter units.The aforesaid hood fulfills these specific needs providing a method that enables a filter unit to be removed in safety conditions both for workers and environment. With reference to the drawing that illustrates a schematic and section side view of a laboratory extraction hood: The laboratory extraction hood 1 comprises a containing chamber 3 or booth, and aworktop 4 made of a material with great mechanical resistance that is highlyresistant to corrosion, such as a stainless steel of the AISI 316 type. The containing chamber 3 is bounded by a wall 5 provided with a front opening to enable anoperator 6 to handle samples to be analyzed on the worktop 4.

On the worktop 4 a passage 7 is obtained for conveying the air. The passage 7extends along a zone located below a worktop 4 and above a space 8 dedicated tofiltering the air. During operation, the sucked air penetrates the chamber 3, isconveyed to the worktop 4 and is subsequently made to flow through the passage 7to the space 8 underneath. In the space 8, through an access opening that is closable with a removable hatch,a filter unit 9 is hostable. The filter unit 9 comprises one or more5 filters of the so-called HEPA and/or of the ULPA type and/or of the active carbontype. The laboratory extraction hood 1 comprises an electric aspirator 27 that has thefunction of sucking air from the containing chamber 3 to make the air flow firstthrough the passage 7, then through the filter unit 9, to retain the hazardoussubstances, and then evacuate the air from the laboratory extraction hood 1 throughan upper evacuation opening 10. An active-carbon filter 40 is located in a positionupstream of the electric aspirator 27 with respect to the direction of advancement ofthe air flow: this active-carbon filter 40 acts on the air flow being expelled beforethe electric aspirator 27 to retain possible acetone fumes.

The filter unit 9 is contained in a filter enclosure housing 11, having a box shape,which is suitable for being inserted into the space 8 of the laboratory extraction hood1. The enclosure housing 11 is open above, in particular comprises an opening zone 12through which the filter unit 9 can receive, and interact with, the flow of air comingfrom the containing chamber 3, to retain the toxic contaminating substances. The laboratory extraction hood 1 is configured for operating, if required, with alaminar flow inside the containing chamber 3: in this case, part of the air isreintroduced into the containing chamber 3 and part is evacuated to the exterior andreplaced with other air taken from the exterior and introduced into the containing chamber 3. It is thus clear that this innovation enable filter extracting operations to be made completely safe: upon removing the filter unit, the fibers, (which are knownto be invisible and highly volatile) are not dispersed in the surrounding environment, preventing severe risks to the health of anyone who may come into contact therewith: operators, technicians, third people as fibers are carried around.

Furthermore, laboratory decontamination is not required anymore when filters replacement is needed. This technological innovation allows employers to fulfill European rules requirements in risk management as arising from exposure to carcinogens, mutagens, asbestos fibers at workplace as stated by Directive 2004/37/EC and Directive 2009/148/EC. The technological innovation as described is fully compliant with provisions of art. 6 of Directive 89/391/EC as transposed by Article 15, paragraph 1, letter c) of the afore mentioned Legislative Decree 81/2008, “elimination of risks in relation to knowledge gained on the basis of technical progress and, where this is not possible, their reduction to a minimum”, and Article 18 paragraph 1 letter z) “the employer ……updates the prevention measure ………, or rather in relation to the degree of evolution of the prevention and protection technique.”

Opinion

Opinion