Impact Factor : 0.548

- NLM ID: 101723284

- OCoLC: 999826537

- LCCN: 2017202541

M Vasubabu1, R Jeevan Kumar1*, T Ramprasad1,2 and E Rekha1

Received: November 11, 2017; Published: December 12, 2017

Corresponding author: R Jeevan Kumar, Molecular Bio-physical Laboratories, Department of Physics, Sri Krishnadevaraya University, Anantapur- 515 055, India

DOI: 10.26717/BJSTR.2017.01.000583

Acrylic is a polymer material made of poly methyal acrylate used as polymer electrolytes, complex polymer preparation and dental base material for fixation. Acylic Polymeric materials reinforced with ceramic compositions provide advantages of high stiffness and strength to weight ratio as compared to conventional denture. The main objective of this work is to study variation in sturctural and physical and chemical transformations such as glass transition and degradations of Acrylic based denture materials such as Acralyn-H, RR Cold Cure material and Quick Ashvin were analyzed by X-ray diffraction, TGA and DTA.

Keywords: Acrylic based denture materials; X-rd TGA; DTA; Transition temperature; Degradations

Acrylic resins were first utilized as denture base materials. Poly (methyl methacrylate) is the primary base resin used today. Polymerization of poly (methyl methacrylate) may be effected by heating the polymer–monomer mixture in a water bath, by chemical activation at room temperature using a material such as dimethyl-p-toluidine, or by activating the reaction using microwave energy or visible light [1]. Addition polymerization requires the activation of the initiator (benzoyl peroxide) to provide free radicals. Polymerization takes place as the free radicals open the double bonds of the methyl methacrylate, creating a chain reaction where the monomer attaches to polymer free radicals. Barron, Rueggeberg & Schuster [2] stated that the degree of monomer conversion of resin materials is a measure of the carbon double bonds (C=C) converted into carbon single bonds (C–C).

The goal of conventional/ rapid curing of acrylic resins is to completely polymerize the resin without porosity. In the conventional/ rapid curing methods, the monomer molecules are moved by thermal shocks from other molecules, and passively moved due to external heat. In the microwave method, the monomer molecules are moved by internal heat produced by a high-frequency electro-magnetic field [3-6]. This investigation involves structural and chemical changes in different resins by using thermal analysis.

Three denture base resins namely Acralyn-H, RR Cold Cure material and Quick Ashvin were polymerized using casting method, then samples are used characterized by x-Ray diffraction technique polymerization changes are analyzed by using TG-DTA.

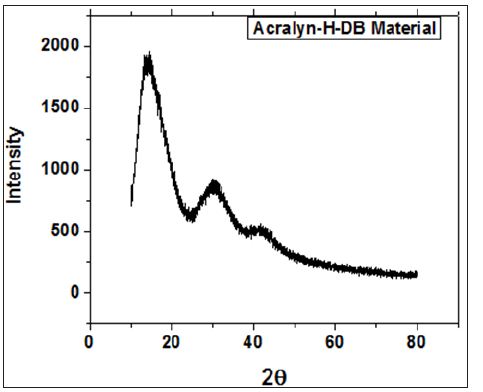

The typical X-ray diffraction patterns were obtained in the present investigations for the various compositions as shown in the Fig.1 represents partially crystalline nature with peaks of three phases .The broad peak in the XRD pattern corresponds to the amorphous region of the material. The intensity of the crystalline peak same in all acrylic based resins. It clearly indicates that the crystallinity of acrylic based resin is due to thermoplastic phase. The acrylic based resin exhibits higher percentage shows more amorphous.

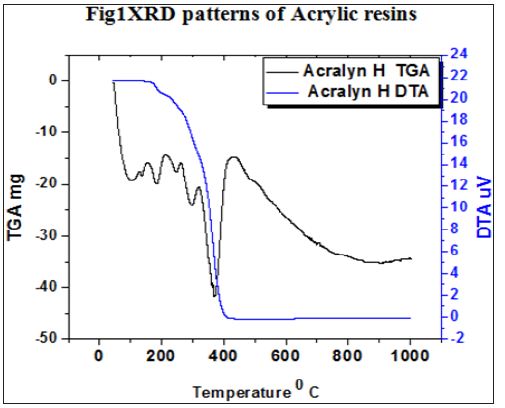

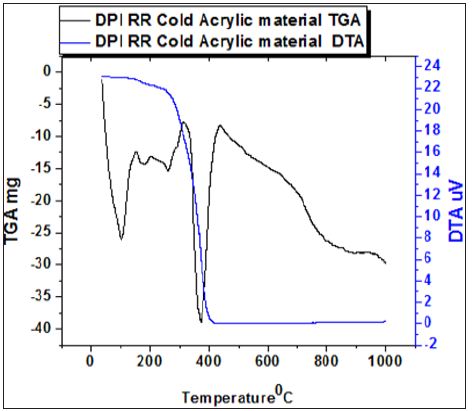

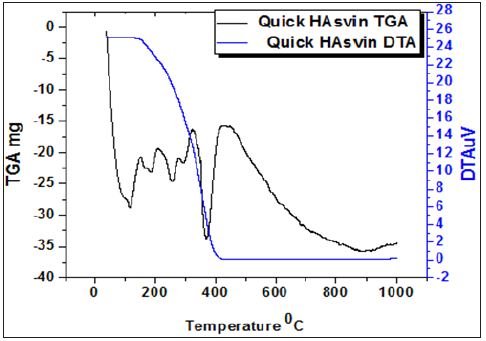

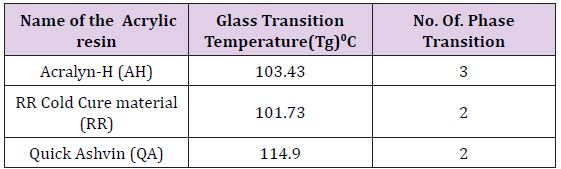

In the dental restorations, specific resin systems are applied to the damaged tooth area to form a cast restoration that is then heat-treated using special ovens under controlled laboratory conditions. The ideal temperature for heat treatment application depends on the thermal behavior of each composite, such as glass transition temperature (Tg) analysis and initial degradation temperature [7]. The Tg can successfully be used as a reference to sign the ideal heat treatment for photo-irradiated resin composites. Above Tg, the secondary molecular interactions are weakened and, as a consequence, material properties are optimized once trapped radicals are given the opportunity to react [8-9]. In addition, the maximum temperature for heating without damaging, i.e., initial degradation temperature, needs to be determined to avoid weight loss [10]. In the present investigation, Conventional TG-DTA is a powerful and convenient thermal analysis technique which allows various important physical and chemical transformations such as glass transition and degradations are examined (Figures 1-4). Glass transition temperature (Tg) and number of phase transitions are evaluated for different dental materials are shown in Table 1.

Figure 1:

Figure 2: XRD patterns of Acrylic resins.

Figure 3: TG-DTA patterns of DPI_RR Cold cure resin.

Figure 4: TG-DTA patterns of Quick Aswin resin.

Table 1: Data on Thermal analysis of Acrylic resin.

a) This method of quantifying degree of polymerization represents a repeatable and expedient analysis of monomer conversion without the use of an internal standard.

b) All resins obtained similar degrees of peaks determined by XRD.

c) Acrylic resin such as Acralyn-H, RR Cold Cure material and Quick Ashvin values for the casting technique, though statistically significantly variation in weight percent with variable glass transition temperature (Tg).