Impact Factor : 0.548

- NLM ID: 101723284

- OCoLC: 999826537

- LCCN: 2017202541

Seongwoo Woo1*, Dennis L O’Neal2, Yimer Mohammed Hassen1, Gezae Mebrahtu1 and Hadush Tedros Alem1

Received: January 18, 2024; Published: February 09, 2024

*Corresponding author: Seongwoo Woo, Manufacturing Technology, Mechanical Technology, Ethiopian Technical University, Addis Ababa, Ethiopia

DOI: 10.26717/BJSTR.2024.55.008634

To raise the fatigue life of mechanical system randomely vibrated in transit, parametric Accelerated Life Testing (ALT) as organized procedure is proffered, which is generated in life–stress type and sample size. The arranged steps allow engineer to uncover the constructional weakness that has a notable consequence on reliability. Finally, company may halt to occur recalls from the market. As a case, upgrading the life of mechanical systems during transit was examined.

Keywords: Mechanical Product; Mechanical System; Parametric ALT; Transit, Fatigue; Design Imperfections

The system worked by machine transmits (generated) power to retain a planned result that necessitates forces & motion and gains mechanical advantages by correctly attaining unknown mechanisms. By carrying out the refrigerating cycle, a household refrigerator allows conditioned air from evaporator to refrigerator & freezer section. In the process, foods in each freezer and refrigerator section can be kept freshly. Refrigerator is formed of compressor, condenser, capillary, and evaporator. It should be devised to properly work under the occurrences actually employed by the end-user. As there are design weakness in the construction, it cannot immediately work in its presumed life (Figure 1). When discovering them by reliability testing, a designer may work out it in the most optimized mode [1]. It holds:

• An ALT scheme,

• Load investigation,

• An ALTs with some alternations, and

• The ability to judge well if product gets to the desired BX lifetime. As an instance investigation, the mechanical systems in transit will be examined.

Parametric ALT in Mechanical Product

Answering for the Schrodinger’s governing formulation can be found:

Linear transport shall be described:

J = LX (2)

As an instance, solid-state diffusion, J, shall be abridged

As Equation (3) places the inverse, the life-stress (LS) type shall be explained:

In Equation (4) the

1)

2)

3)

As the effect materializes from effort in transmitting power, Equation (4) shall be restated as:

To attain the acceleration factor (AF), declared as the relatedness between the raised-level stress and ordinary stress, it shall be defined as:

To achieve the mission cycles for aimed life - B1 life of ten years, sample size unified with Equation (6) may be defined as [2]:

Case Investigation: Upgrading the Fatigue Life of a Household Refrigerator Exposed to Random Vibrations in Transported by Rail

Refrigerators were transported from the Los Angeles located in the West Coast to consumers who resided in the East Coast of the United States. This journey of seven days was 7,200 km for a whole travel period. As stated by field statistics, after refrigerators exposed to random vibrations in the rail transportation route (US) were shipped, they did not function because the compressor rubbers were torn and the attaching tubes were broken, accompanying by designers to ask for replacing it. That is, in the US, the interval at which first unsuccessfulness happened over two days was about 2,500 km in rail transit. In Chicago, 27% of the conveyed products was unsuccessful. As the refrigerators moved the 7,200-km interval from West Coast to Boston over seven days, 67% of the products was unsuccessful. It was obvious that the failed refrigerators had design defects. To correctly function the refrigerator for its presumed life in transit, after identifying them by laboratory tests such as parametric ALT, the manufacturer had to modify the problems (Figure 2).

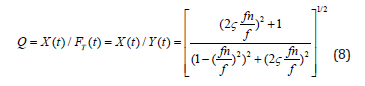

Due to the foundation load, Y, the force transmissibility, Q, can be expressed:

where X is the unvarying solution in a physical process, FT is the induced force, Y is the span of base excitations, r is the frequency proportion

As the stress in transportation comes from the conveyed vibration loads, FT, which may be stated as the power spectral density (PSD) level of acceleration for a determined frequency band, Equation (5) may be expressed:

Thus, found on Equation (6), the AF can be stated:

where a1 is the raised PSD level for the given frequency band, a0 is the usual PSD level for the given frequency band, R, amplitude ratio of gravitational acceleration. After examining the calculated vibration spectra, the natural frequencies of vibration (left ↔ right and up ↔ down) were 5 Hz and 9 Hz. The damping ratio was expected to have ζ= 0.1 with a settling time of 2 sec and about 5% overshoot. The frequency proportion also was expected to have r

In the 1st ALT, the failures of the stress levels — 1.00 Grms at the natural frequency