Impact Factor : 0.548

- NLM ID: 101723284

- OCoLC: 999826537

- LCCN: 2017202541

Khandakar Akhter Hossain*

Received: September 24, 2017; Published: October 11, 2017

Corresponding author: Khandakar Akhter Hossain, Chief Naval Architect and Marine Engineer, BN GuidedMissile Corvette Project, Wuchang Shipbuilding Industry Co Ltd, Wuhan, China

DOI: 10.26717/BJSTR.2017.01.000428

The fabric of a ship, whether of wood a century ago, or steel today has always had considerable value. Ship recycling is an engineering process [1] of dismantling obsolete ship to collect useable materials. One interesting point is that, the shipping industry is well ahead of other industries, such as the automotive and aviation sectors, in re-using some 85-98% of a ship by weight. On the other hand, even if ship recycling has been efficient in providing a ready supply of steel and other metals for re-use, there has been a cost in terms of lives lost and local environmental impact. The demolition of ships is widely associated with dangerous practices and pollution. Cutting apart big steel structures is a complex and hazardous business. And even though a high proportion by weight of the ship’s structure is re-usable, there are significant amounts of plastics, chemical product and other materials that should be handled carefully and appropriately. However, there are few dozen operational ship-recycling yards located along coastal belt at Chittagong of Bangladesh [2] comprehensively. This industry provide main source of steel, create huge employment [3] and generates large amounts of revenues for the government of Bangladesh. It is also contributing to the local shipbuilding industry.

Abbreviations:PPE: Personal Protective Equipment; SBSRB: Ship Building and Ship Recycling Board; MOI: Ministry of Industry; DOE: The Department of Environment; ECC: Environmental Clearance Certificates; BSBA: Bangladesh Ship Breaker Association; MT: Metric Ton; LDT: Light Dead Weight Ton

Local ship recycling yards are following beaching method for recycling the ship. The beaching method is the most common ship demolition today, make it difficult to ensure safety and to contain and manage pollutants. In this method, ship is beached over the flat muddy land where it is dismantled to small parts using semi-skilled and unskilled labor. Then the dismantled parts are pulled to the dry shore area using electric winch and labor force. Gas cutting is widely used to make relatively small pieces from the steel structure. Usually, minimum knowledge of safety is needed in this process and that leads to some accidents like explosion, causing death, fatal injuries and permanent disabilities. Apart from economic benefit from this industry, the social and environmental costs demand huge attention for further development [4].

The improper storage and disposal of hazardous material (HazMat), result in air, soil and water contamination [5]. In many ship breaking yards in south Asia and particularly in Bangladesh, workers are not using proper personal protective equipment (PPE), such as skin, eye or lung protection. It’s mainly managerial and motivational failure to workforce along with socio-economic problem of the country. There is usually less equipment for machine, fire, and chemical safety. With a few exceptions, the vast majority of workers do not receive proper information on the hazards or risks to health and safety, nor do they receive require training [6]. Most of the local ship recycling yards neither have good containment to prevent pollution of soil, air, marine and freshwater resources, nor follow the appropriate technology to ensure the environmentally safe management [3] and disposal of hazardous wastes and materials.

It is no doubt that ship breaking is necessary for South Asia, particularly for Bangladesh. We should ensure that our ship recycling yards are maintaining at least minimum standard in respect of health, safety & environmental issues. It does not necessarily to imply that we have to follow dry docking instead of beaching, rather keeping the beaching method intact, we can improve the situation by providing some common facilities and training, which we are lacking now. At present, Bangladesh Government has established the “Ship Building and Ship Recycling Board” (SBSRB) as the onestop service provider under the Ministry of Industry (MOI). After operational, it is providing integrated services including granting required permissions and certificates for Ship breaking, recycling and other related activities in cooperation with other responsible departments and ministries [7].

The Department of Environment (DOE) was placed under the MOEF in 1989 as its technical wing and is statutorily responsible for the implementation of the Environment Conservation Act, 1995. DOE is working to ensure sustainable environmental governance for pollution control. This department is solely responsible for issuing an Environmental Clearance Certificates (ECC) prior to the establishment of any industrial unit in Bangladesh and thus ship recycling yards as well. It also issues authorizations for handling hazardous wastes generated from ship recycling activities. On the other hand, Bangladesh Ship Breaker Association (BSBA) is a representative body of ship recyclers or yards in Bangladesh established in 2003. This trade organization is working in the interests of ship recycling activities, safeguarding the rights of its members and ensuring environmentally sound ship recycling.

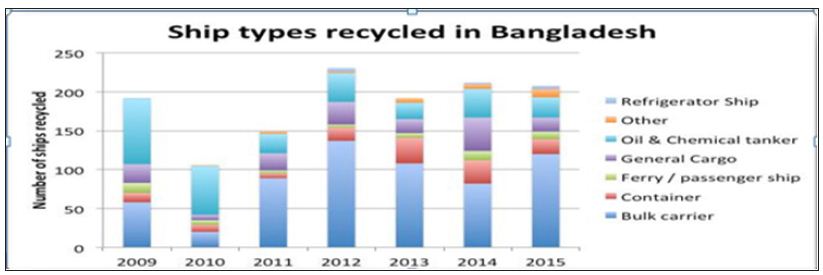

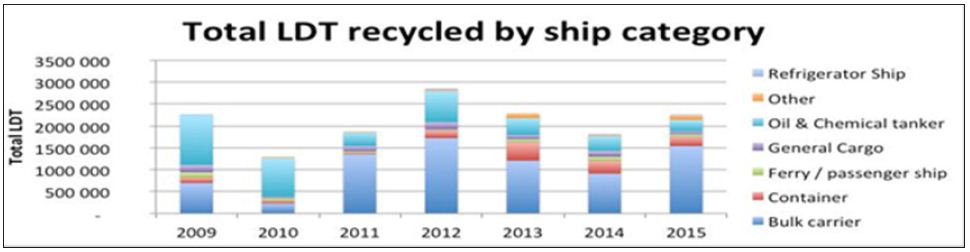

The world-wide ship recycling industry dismantles around 1,000 large ocean-going vessels per year. If we look to the on ground statistics of ship recycling yards of Bangladesh, we can see that, average 200 different types of obsolete ships are recycled annually in different yards located in Chittagong. Those different types of ships are bulk carrier, tanker, container carrier, cargo carrier, passenger or ferry, refrigerator ship, floating pontoon/restaurant, and other different types of ships. In (Figure 1), total number of different types/category of ships recycled annually in Bangladesh between the years 2009 to 2015 has been shown. Again, from on ground statistics of ship recycling yards of Bangladesh, we can see that, average 2000000 Metric Ton (MT) or Light Dead-Weight Ton (LDT) different types of obsolete ships are recycled annually in different yards in Bangladesh. In Figure 2, total LDT of different types/category of ships recycled in Bangladesh between the years 2009 to 2015 has been shown Figure 2.

Figure 1 : Total number of ships recycled in Bangladesh by type/category between the years 2009 to 2015.

Figure 2 : Total number of ships recycled in Bangladesh by type/category between the years 2009 to 2015.

To determined the total amount of reusable material in MT and reusable material factor in percentage of local ship recycling industry in Bangladesh; author has been involved directly with the local ship recycling yards since last eight years. Author collect and made inventory of materials, equipments, machinery, items and HazMat on different types of ships recycled in local yards in different years from 2009 to 2016. Total 27 in number of different types/category of recycled ships has been considered as sample to calculate the average annual amount of reusable materials output. It has been determined that, there are average 1,833,461 MT (minimum) and up to 1,989,252 MT (maximum) reusable material produce annually from ships recycling industry of Bangladesh. In Table 1, reusable material factor and amount of materials output per year in MT for different types of recycled ships in Bangladesh has been shown.

Table 1 : Reusable material factor and amount of materials output per year in MT for different types of recycled ships in Bangladesh (between the years 2009 to 2015).